Epoxy mortar and terrace coating

A technology of epoxy mortar and epoxy resin, which is applied in the field of construction, can solve the problems of low compressive strength and poor wear resistance, and achieve the effects of improving wear resistance and compressive strength, high corrosion resistance, and inhibiting settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

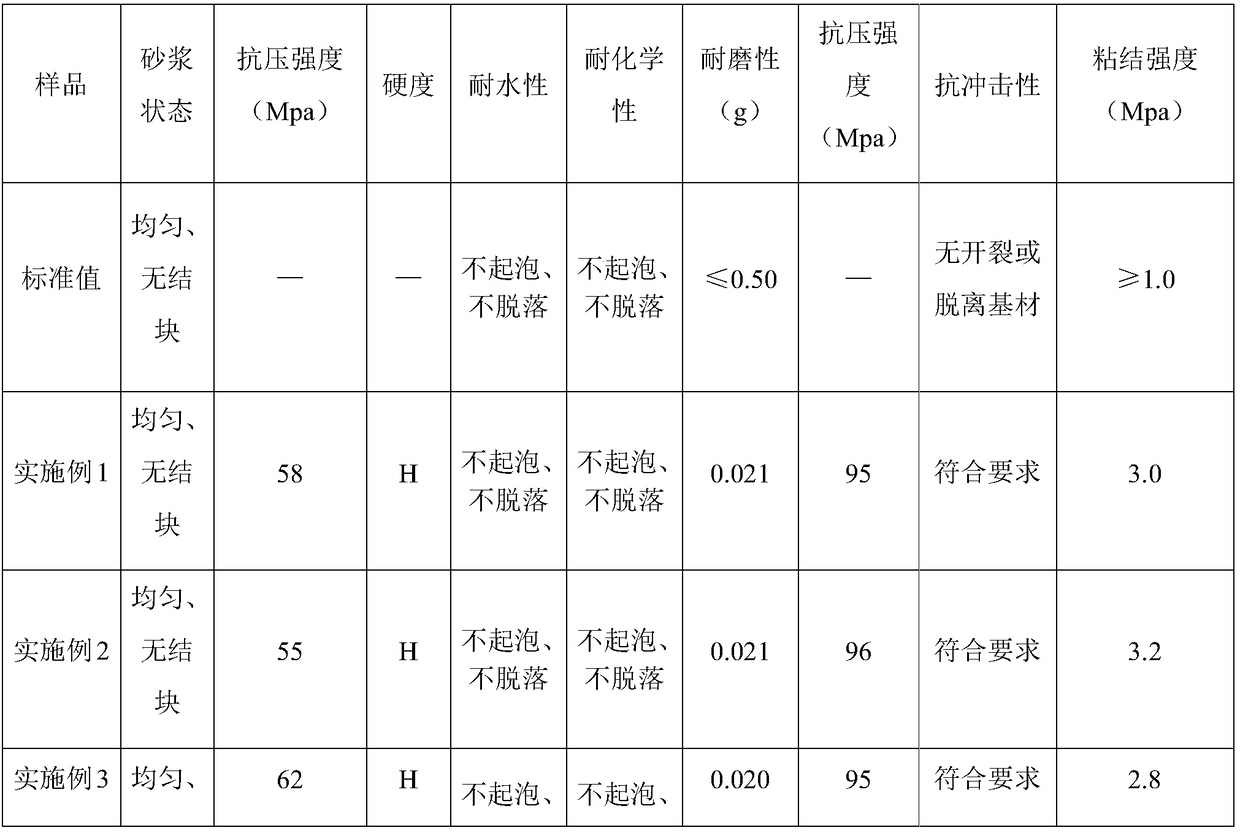

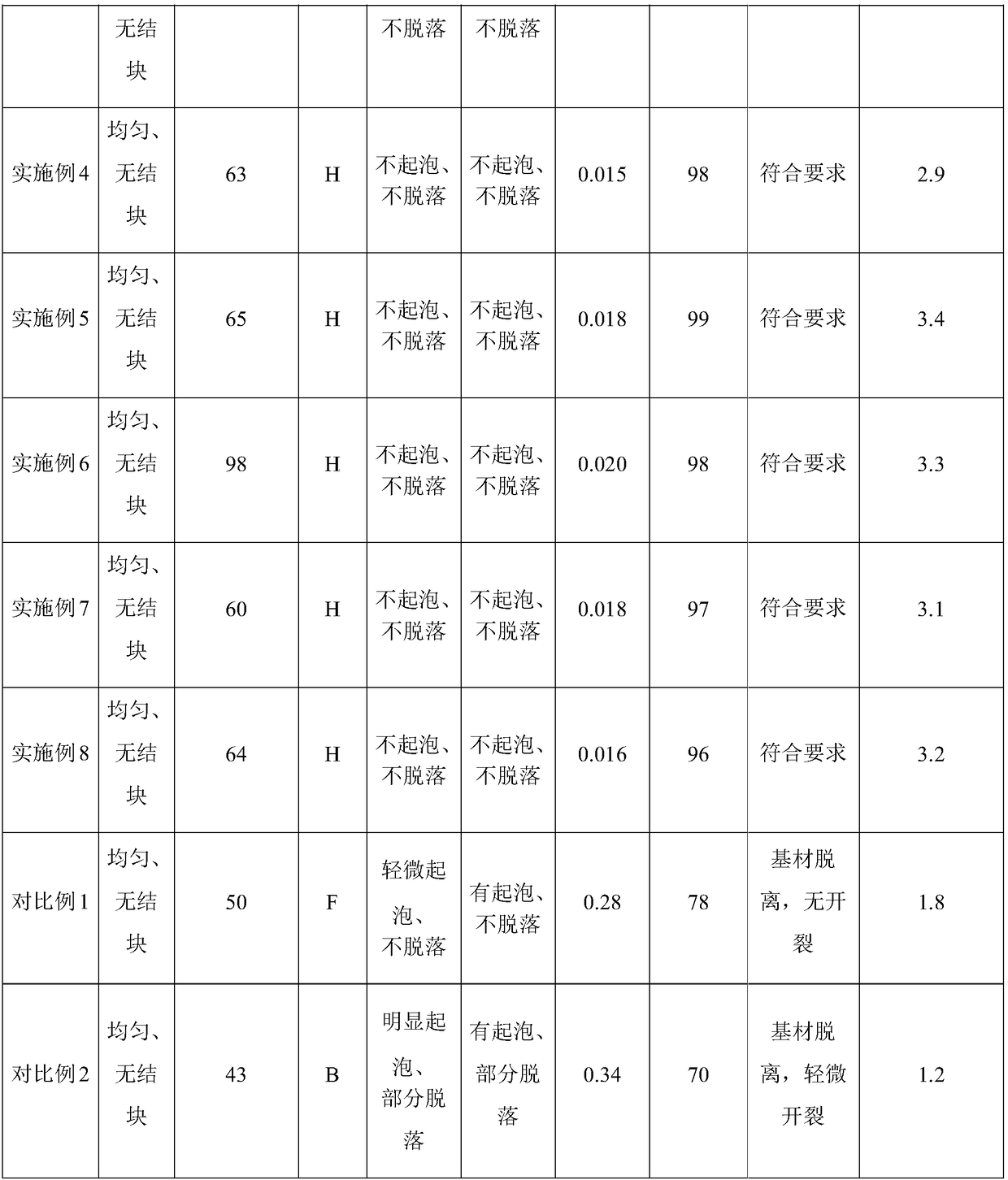

Examples

preparation example Construction

[0072] The preparation method of epoxy mortar of the present invention comprises:

[0073] (1) First mix epoxy resin and active diluent at a speed of 120-180r / min for at least 3 minutes, then add defoamer, rheological agent and surfactant in turn, and then mix at a speed of 180r / min for 3 minutes ~6min, prepare A component, and seal it, and keep it heat-insulated.

[0074] (2) Mix the curing agent and the accelerator at 120-180r / min for 3-6 minutes to prepare component B, and keep it sealed and heat-insulated.

[0075] (3) Mix the filler, glass fiber reinforced plastic wear-resistant aggregate and quartz sand through a mixer for 3-6 minutes to prepare component C, and keep it sealed.

[0076] (4) Mix components A and B at a speed of 120 to 180r / min for 2 to 6 minutes, then add component C and mix at a speed of 180r / min for 3 to 6 minutes; components A and B The mass ratio to component C is (1.7-2): (0.8-1): (4-6).

[0077] The present invention also provides a floor paint, ...

Embodiment 1

[0081] An epoxy mortar, including component A, component B and component C, the mass ratio of component A, component B and component C is 1.7:0.9:6;

[0082] Component A is composed of the following raw materials in parts by weight: 85 parts of bisphenol A epoxy resin, 8 parts of allyl glycidyl ether, 3 parts of silicone defoamer, 3 parts of organic bentonite and high-carbon fatty alcohol polyoxygen 1 part vinyl ether;

[0083] Component B is composed of the following raw materials in parts by weight: 94 parts of isophorone diamine and 6 parts of 2,4,6-tris(dimethylamino)phenol;

[0084] Component C is composed of the following raw materials in parts by weight: 70 parts of quartz sand, 20 parts of fiberglass wear-resistant aggregate and 10 parts of heavy calcium powder;

[0085] Wherein, the epoxy equivalent in the bisphenol A type epoxy resin is 150 and the hydroxyl equivalent is 100;

[0086] The particle size of the quartz sand is 80-120 mesh graded quartz sand;

[0087]...

Embodiment 2

[0095] An epoxy mortar, including component A, component B and component C, the mass ratio of component A, component B and component C is 2:0.9:4;

[0096] Component A is composed of the following raw materials in parts by weight: 88 parts of bisphenol A epoxy resin, 5 parts of allyl glycidyl ether, 1 part of silicone defoamer, 4 parts of organic bentonite and high-carbon fatty alcohol polyoxygen 2 parts vinyl ether;

[0097] Component B is composed of the following raw materials in parts by weight: 92 parts of isophorone diamine and 8 parts of 2,4,6-tris(dimethylamino)phenol;

[0098] Component C is composed of the following raw materials in parts by weight: 75 parts of quartz sand, 15 parts of fiberglass wear-resistant aggregate and 10 parts of heavy calcium powder;

[0099] Wherein, the epoxy equivalent in the bisphenol A type epoxy resin is 200 and the hydroxyl equivalent is 70;

[0100] Quartz sand adopts graded quartz sand with a particle size of 80-120 mesh;

[0101]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com