Styrene-acrylic negative ion coating containing formaldehyde catching agent

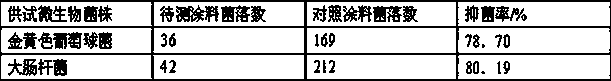

A technology of formaldehyde scavenger and negative ion paint, which is applied in the field of styrene-acrylic negative ion paint and its preparation, can solve the problems of easy aging safety hazards, easy fading, yellowing, etc., and achieve improved construction performance, environmental protection and energy saving performance, good sterilization effect, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of styrene-acrylic negative ion coating that contains formaldehyde scavenger, its raw material comprises the following components by weight: 10 parts of styrene-acrylic emulsion, 10 parts of diatomaceous earth, 10 parts of nano-titanium dioxide slurry, 4 parts of antibacterial nano-titanium dioxide, powder ash 50 parts, 10 parts of titanium dioxide, 10 parts of heavy calcium carbonate, 1 part of negative ion powder, 1 part of hydroxyethyl cellulose solution, 3 parts of formaldehyde capture agent, 0.5 part of dispersant, 0.2 part of defoamer, film-forming aid 1.0 parts, 0.5 parts of thickener, 1 part of antifreeze, 40 parts of deionized water.

[0028] The titanium dioxide rutile type titanium dioxide has a particle size of 100 μm.

[0029] The negative ion powder is tourmaline powder with a particle size of 80nm.

[0030] The formaldehyde scavenger is adipic acid dihydrazide.

[0031] The dispersant sodium tripolyphosphate.

[0032] Described defoamer is AMP-1...

Embodiment 2

[0041]A kind of styrene-acrylic negative ion coating that contains formaldehyde scavenger, its raw material comprises the following components by weight: 20 parts of styrene-acrylic emulsion, 20 parts of diatomaceous earth, 16 parts of nano-titanium dioxide slurry, 6 parts of antibacterial nano-titanium dioxide, powder ash 60 parts, 20 parts of titanium dioxide, 20 parts of heavy calcium carbonate, 3 parts of negative ion powder, 3 parts of hydroxyethyl cellulose solution, 5 parts of formaldehyde capture agent, 1.0 parts of dispersion, 0.5 parts of defoamer, 2.5 parts of film-forming aid 0.9 parts of thickener, 3 parts of antifreeze, 60 parts of deionized water.

[0042] The titanium dioxide rutile type titanium dioxide has a particle size of 150 μm.

[0043] The negative ion powder is tourmaline powder with a particle size of 150nm.

[0044] The formaldehyde scavenger is adipic acid dihydrazide.

[0045] The dispersant sodium tripolyphosphate.

[0046] Described defoamer i...

Embodiment 3

[0055] A kind of styrene-acrylic negative ion paint containing formaldehyde scavenger, its raw material comprises the following components by weight: 15 parts of styrene-acrylic emulsion, 15 parts of diatomaceous earth, 12 parts of nano-titanium dioxide slurry, 5 parts of antibacterial nano-titanium dioxide, powder ash 55 parts, 15 parts of titanium dioxide, 15 parts of heavy calcium carbonate, 2 parts of negative ion powder, 2 parts of hydroxyethyl cellulose solution, 4 parts of formaldehyde capture agent, 0.6 part of dispersant, 0.4 part of defoamer, film-forming aid 1.5 parts, thickener 0.8 parts, antifreeze 2 parts, deionized water 45 parts.

[0056] The titanium dioxide rutile type titanium dioxide has a particle size of 120 μm.

[0057] Described anion powder is the tourmaline powder that particle size is 120nm.

[0058] The formaldehyde scavenger is adipic acid dihydrazide.

[0059] The dispersant sodium tripolyphosphate.

[0060] Described defoamer is AMP-19.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com