Equipment and method for producing tetramethyl ammonium hydroxide by using continuous process

A technology of tetramethyl ammonium hydroxide and tetramethyl ammonium carbonate, applied in the direction of electrolytic organic production, cells, electrolytic components, etc., can solve the problems of large changes in electrolyte concentration, affecting product performance, increasing production costs, etc. Small change range, increased lifespan, and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

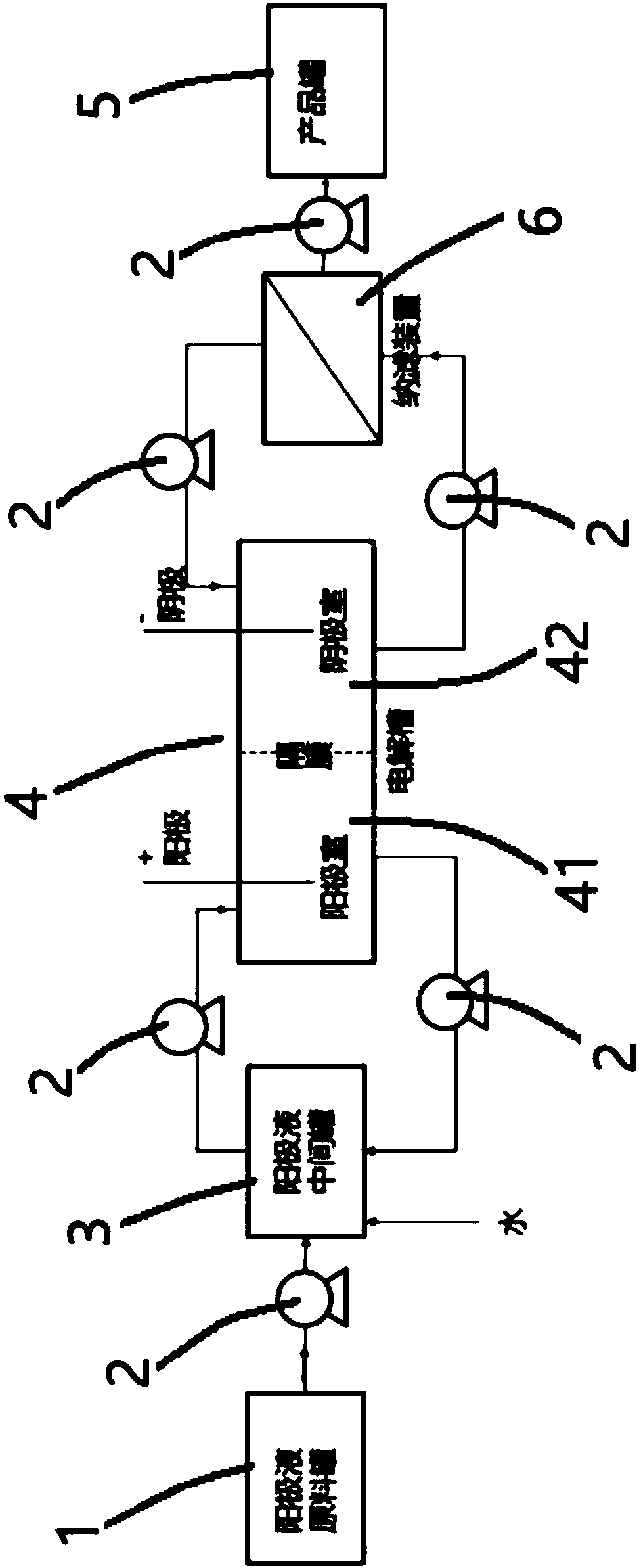

Image

Examples

Embodiment 1

[0032] Tetramethylammonium carbonate is the raw material, and the concentration of tetramethylammonium carbonate in the anolyte raw material tank is 65%. In the initial stage, the concentration of tetramethylammonium carbonate is 35% by controlling the ratio of raw materials and water in the anolyte intermediate tank. , and then inject this solution into the anode chamber for electrolysis. As the electrolysis proceeds, the concentration of the anolyte decreases. At this time, part of the anolyte is pumped into the anolyte intermediate tank, and the anolyte intermediate tank is combined with the raw materials and water in the anolyte raw material tank. The concentration of tetramethylammonium carbonate in the tank is 35%, and then this solution is replenished to the anode chamber, so that the anolyte concentration in the anode chamber is kept between 25-30% in circulation. The concentration of tetramethylammonium hydroxide in the cathode chamber continues to rise with the electr...

Embodiment 2

[0034] Tetramethylammonium carbonate is the raw material, and the concentration of tetramethylammonium carbonate in the anolyte raw material tank is 65%. In the initial stage, the concentration of tetramethylammonium carbonate is 35% by controlling the ratio of raw materials and water in the anolyte intermediate tank. , and then inject this solution into the anode chamber for electrolysis. As the electrolysis proceeds, the concentration of the anolyte decreases. At this time, part of the anolyte is pumped into the anolyte intermediate tank, and the anolyte intermediate tank is combined with the raw materials and water in the anolyte raw material tank. The concentration of tetramethylammonium carbonate in the tank is 35%, and then this solution is replenished to the anode chamber, so that the circulation keeps the anolyte concentration in the anode chamber between 25-30%. The concentration of tetramethylammonium hydroxide in the cathode chamber continues to rise as the electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com