Antiallergic plant extracting solution for biological enzyme processing and corrosion resistance as well as preparation method and application of antiallergic plant extracting solution

A plant extract and anti-allergic technology, which is applied in the direction of chemical instruments and methods, plant raw materials, allergic diseases, etc., can solve the problems of low safety and efficacy, weak anti-allergic properties of extracts, etc., and achieve the goal of overcoming compatibility Limitations of application, improvement of anti-allergic ability, strong anti-allergic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of the antiallergic plant extract liquid processed and antiseptic with biological enzyme, described method comprises the following steps:

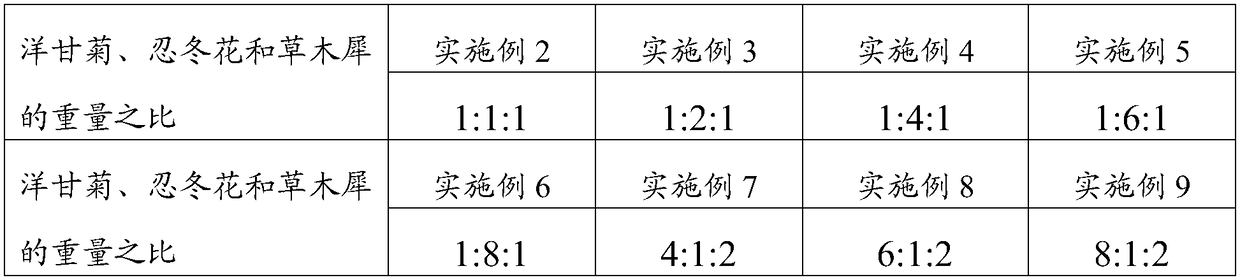

[0028] Step 1, pretreating 10-80 parts of chamomile, 10-80 parts of honeysuckle and 10-80 parts of sweet rhinoceros as raw materials to obtain mixed plant pieces whose length is less than the preset value;

[0029] Specifically, the chamomile is selected from one or a mixture of Roman chamomile (CHAMAEMELUM NOBILE), German chamomile (MATRICARIA RECUTICA) and Moroccan chamomile (ORMENIS MULTICAULIS). Preferably, the chamomile is Roman chamomile. The honeysuckle is selected from one or more of honeysuckle in Guangdong, honeysuckle in Hubei, honeysuckle in Hainan and honeysuckle in Jiangsu. Preferably, the honeysuckle is honeysuckle from Guangdong area. The said sweet rhinoceros is one or two or more of the white-flowered sweet-scented sweet-scented rhinoceros, fine-toothed ...

Embodiment 1

[0070] Clean 20 parts of chamomile, 10 parts of honeysuckle, and 10 parts of sweet rhinoceros, cut into small pieces, mix well, and use a juice extractor to break up; then add 50 parts of water, 9.5 parts of the first enzyme preparation (cellulase 3.5 1 part, 3.5 parts of pectinase, 2.5 parts of xylanase), 1 part of alcohol (1 part of propylene glycol), soaked in a constant temperature water bath at 25 ℃ for 30 minutes; Continue to sonicate for 1 hour at ℃; then stand for stratification, centrifuge or filter to obtain the supernatant; then heat the supernatant at 90℃ for 10 minutes, and after the supernatant cools to room temperature, add 5.5 parts of the second enzyme preparation (2 parts of glucose oxidase, 3.5 parts of lysozyme), and continue to sonicate for 1 h at 25°C to obtain a mixed solution; finally, the mixed solution is passed through a chromatographic column filled with a resin filler, washed with water to remove impurities, and collected The eluent is the antialle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com