A dual optical path laser marking equipment and marking method thereof

A technology of laser marking equipment and dual optical paths, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of accumulated errors, inability to correct deviation, and high cost of two-dimensional platforms, so as to improve production efficiency and ensure processing quality. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

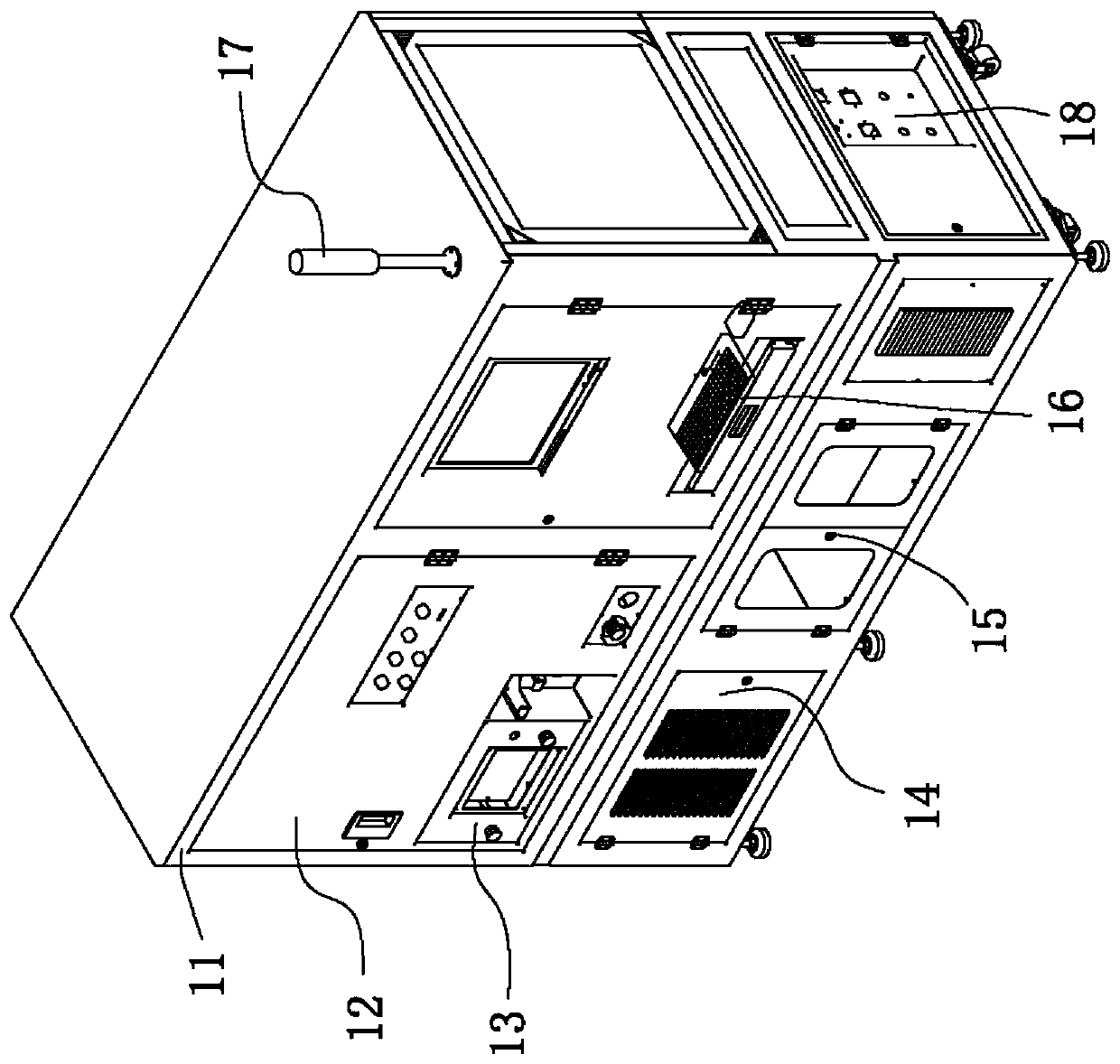

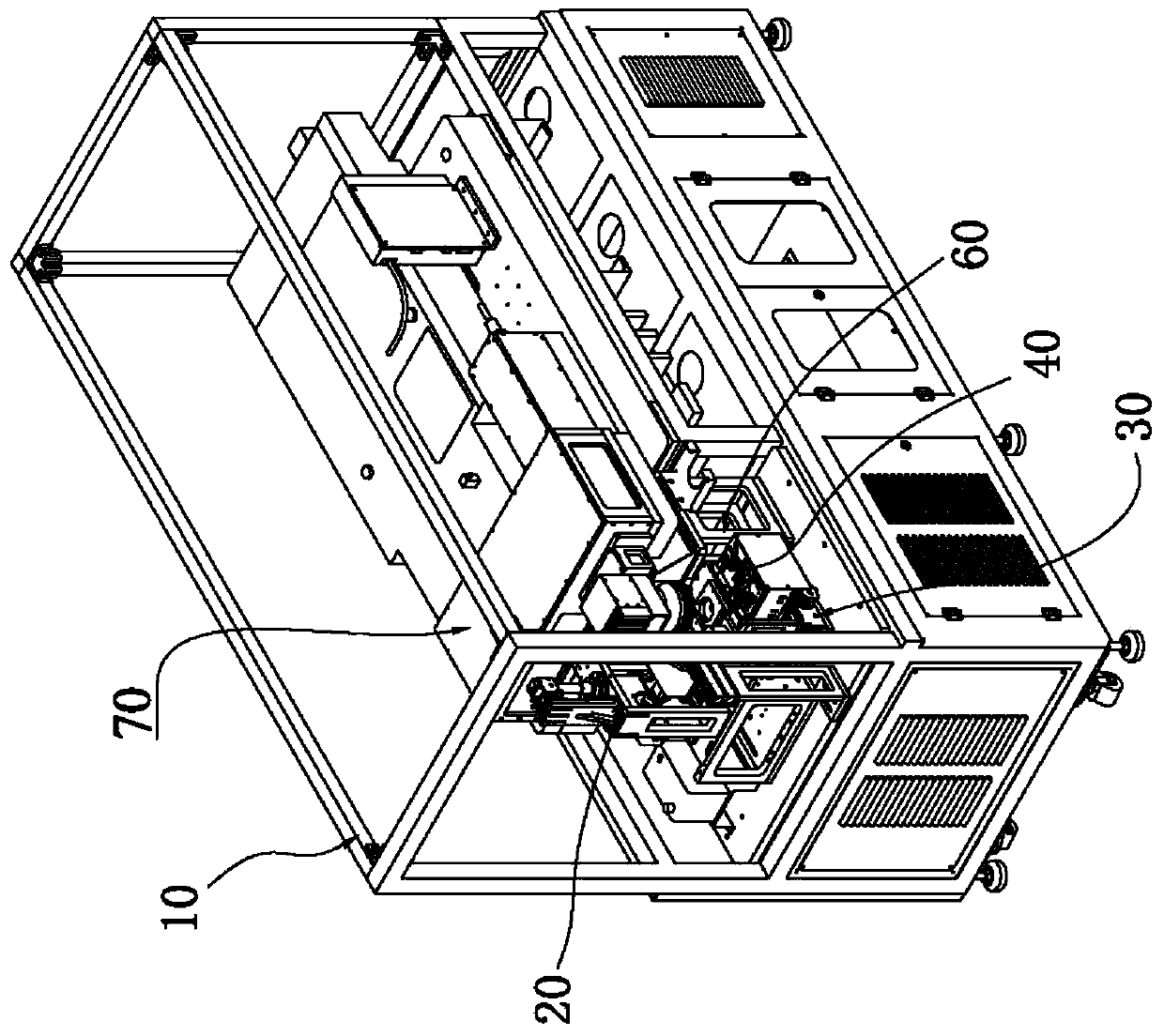

[0045] The present invention is a dual optical path laser marking equipment, which adopts picosecond laser, nanosecond laser, precise optical control system, various high-precision cylinders, and linear guide rails, and is equipped with customized light sources and industrial cameras at the same time, and cooperates with precision fixtures , so as to realize the positioning of the product sheet, implement the picosecond laser for contour processing, and the nanosecond laser to fill the interior of the contour to achieve a 2.5D etching effect on the stainless steel surface.

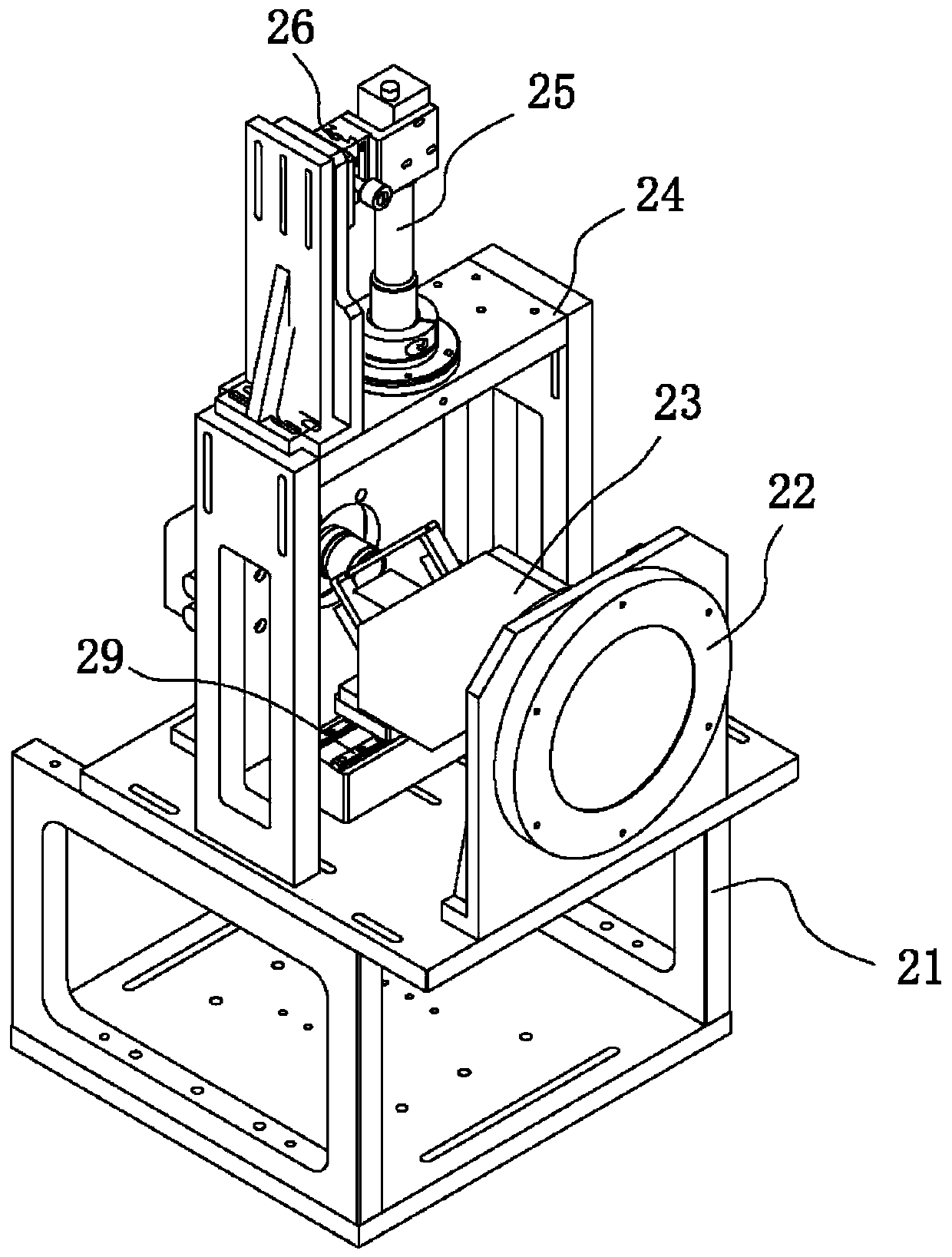

[0046] Such as figure 1 with figure 2 It is a structural schematic diagram of a dual-optical path laser marking equipment, which includes a frame assembly 10, a camera assembly 20, an elevating platform mechanism 30, a jig assembly 40, a mirror assembly 60, an optical and vibrating mirror system 70, and Dust extraction structure 90.

[0047] The frame assembly 10 is welded by a 40mm square hole and cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com