Preparation method of nano composite board for furniture

A kind of composite board and nanotechnology, applied in the field of furniture, can solve the problems of wood boards being difficult to clean and not wear-resistant as a whole, and achieve the effects of easy popularization of production, simple manufacturing method and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

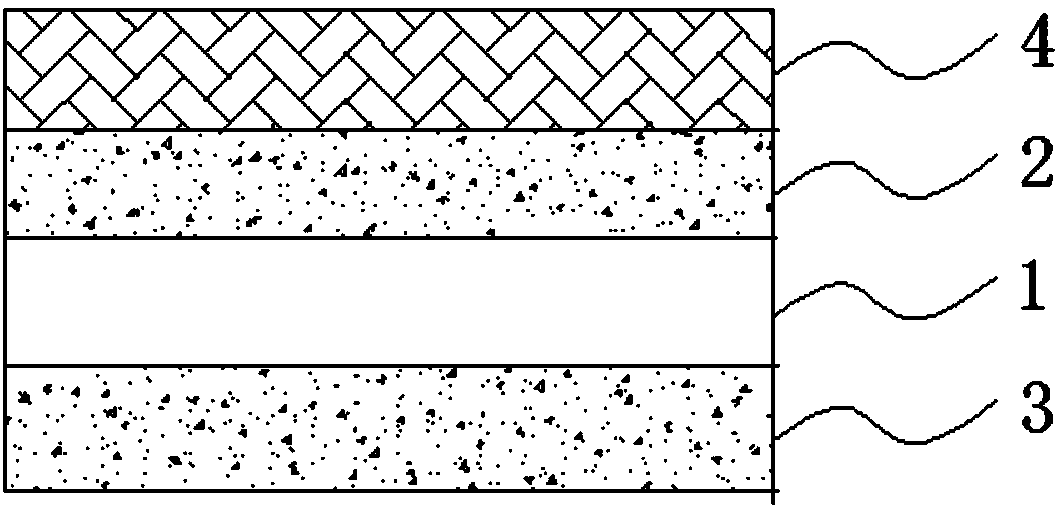

[0036] Example: A preparation method of nano composite board for furniture, such as figure 1 As shown, it includes a nano-substrate, a first wear-resistant layer located on any side of the nano-substrate, a second wear-resistant layer located on the other side of the nano-substrate, and the other side of any one of the first wear-resistant layers Easy to clean layer;

[0037] The preparation method of the nanocomposite board includes the following steps:

[0038] Step 1: Prepare nano-substrate slurry

[0039] The raw materials of the nano-substrate slurry include (in parts by weight): 25-50% nano calcium oxide powder, 20-40% nano silicon carbide powder, 5-15% nano titanium dioxide powder, 18-40% wood fiber, 26-47% of reinforcing fiber, 5-10% of thermoplastic resin, 5-10% of adhesive, 2-6% of thickener and 60-80% of water; each component of the nano-substrate slurry is added to the mixer in proportion Stir evenly to obtain a slurry mixture;

[0040] Step 2: Finalize and dry the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com