Composite die master die as well as manufacturing method and application thereof

A composite material and manufacturing method technology, applied in the field of composite material mold manufacturing, can solve the problems of layer material deformation, difficulty in layer laying, size deviation, etc., and achieve the effects of high mold precision, increased working strength, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

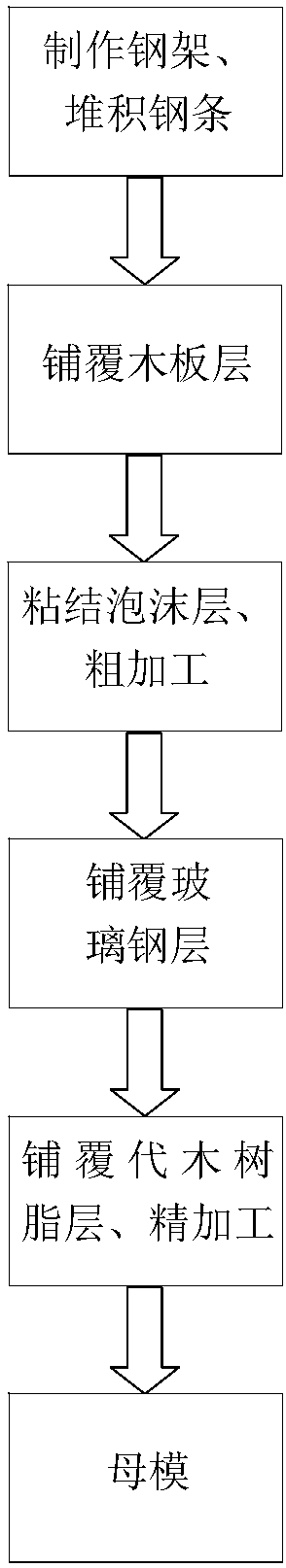

Method used

Image

Examples

preparation example 1

[0082] The preparation of preparation example 1 master model

[0083] This preparation example is carried out in the following way:

[0084] (1) Weld a steel frame (model Q235) with a size of 6000*2500*10mm, and make a steel frame and stack steel bars (45#) on the steel frame to form a steel profile, and then conduct heat treatment at a temperature of 140°C 3 hours.

[0085] (2) Lay a wood layer with a thickness of 20mm on the steel surface to form a wood layer surface (such as figure 2 shown), thereby eliminating the gap between the steel frames;

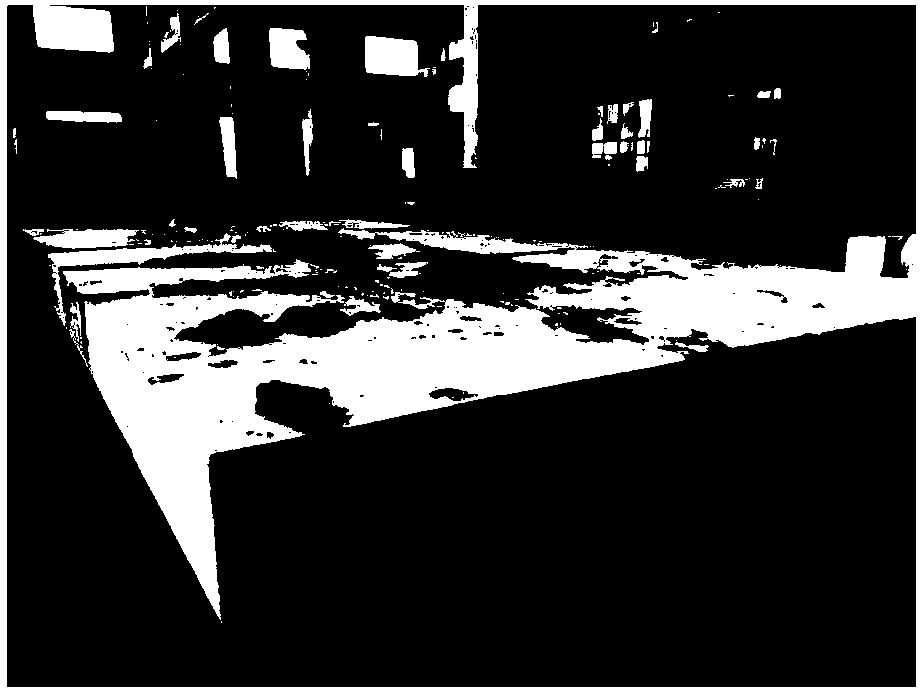

[0086] (c) Adhere a polyurethane foam layer with a thickness of 10mm on the surface of the plank layer and rough machine it until the surface accuracy is about ±3mm to form a rough machined surface; image 3 Prepare site photos for the master model with foam.

[0087] (d) Lay a FRP layer with a thickness of about 5 mm on the foam surface to form a FRP layer profile; then polish the FRP layer to roughen the surface so that the ...

preparation example 2

[0090] It was carried out in substantially the same manner as in Preparation Example 1, except that PS (polystyrene foam) foam was used instead of polyurethane foam.

preparation example 3

[0092] The method was basically the same as that of Preparation Example 1, except that PMI (purchased from Zhejiang Zhongke Hengtai New Material Technology Co., Ltd.) foam was used instead of polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com