Method for dehydrogenating low-carbon alkane by using metal oxide

A low-carbon alkane, oxidative dehydrogenation technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve problems such as difficult industrial promotion, hidden safety hazards, etc., and achieve improved reaction conversion rate and complete heat matching. , to achieve the effect of heat matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0026] Take the oxide of metal vanadium as an example to prepare (each part by mass is 1g), impregnate the carrier into a solution containing metal ions, and then calcine

[0027] Step 1, get 1.8g ammonium metavanadate (NH 4 VO 3 ) and 2.8g oxalic acid (C 2 o 4 h 2 ) was dissolved in 3g deionized water, after the reaction was complete, 2.0gAl 2 o 3 Soak in the above solution, dry at room temperature for 12 hours, and dry at 80°C for 2 hours;

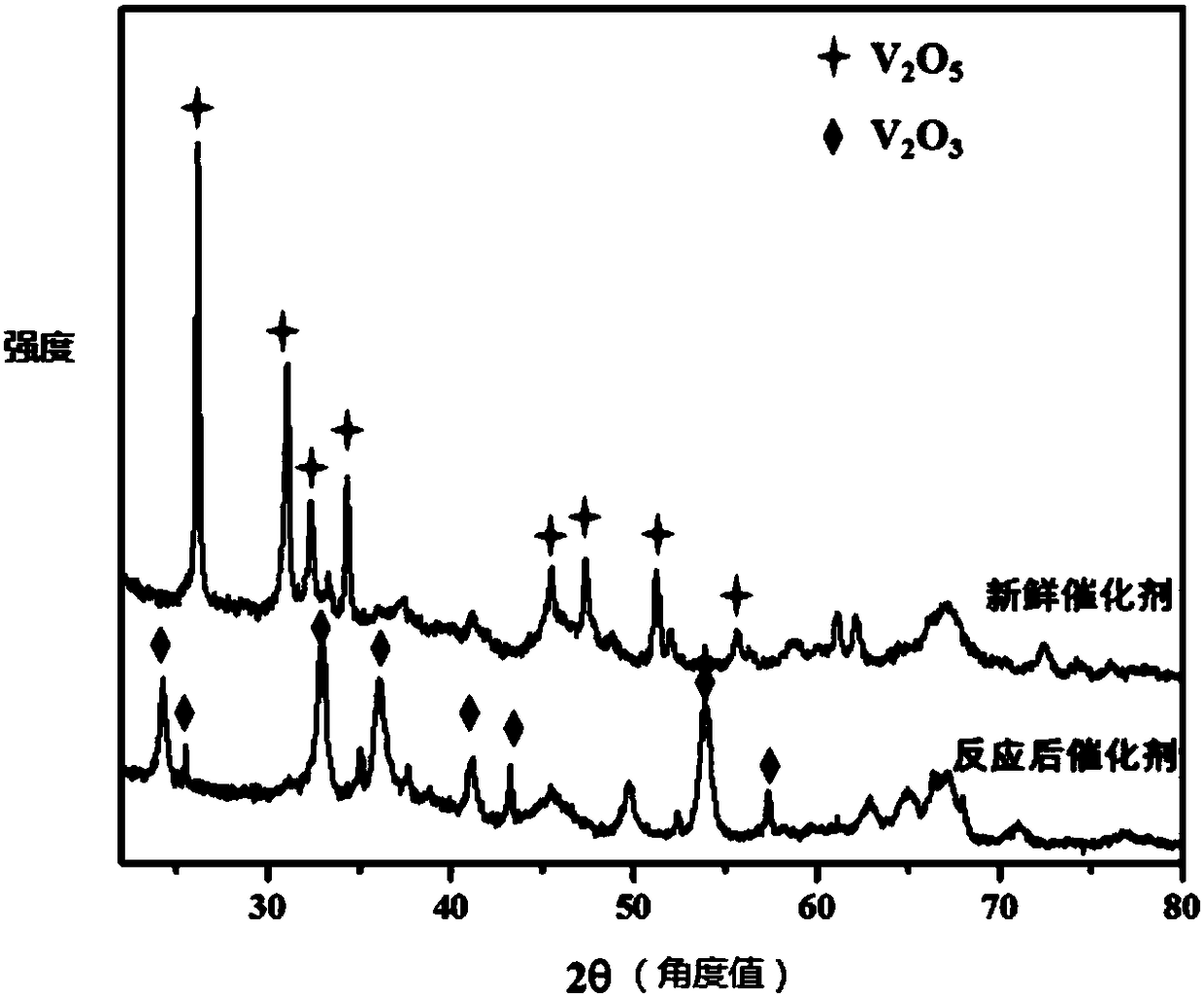

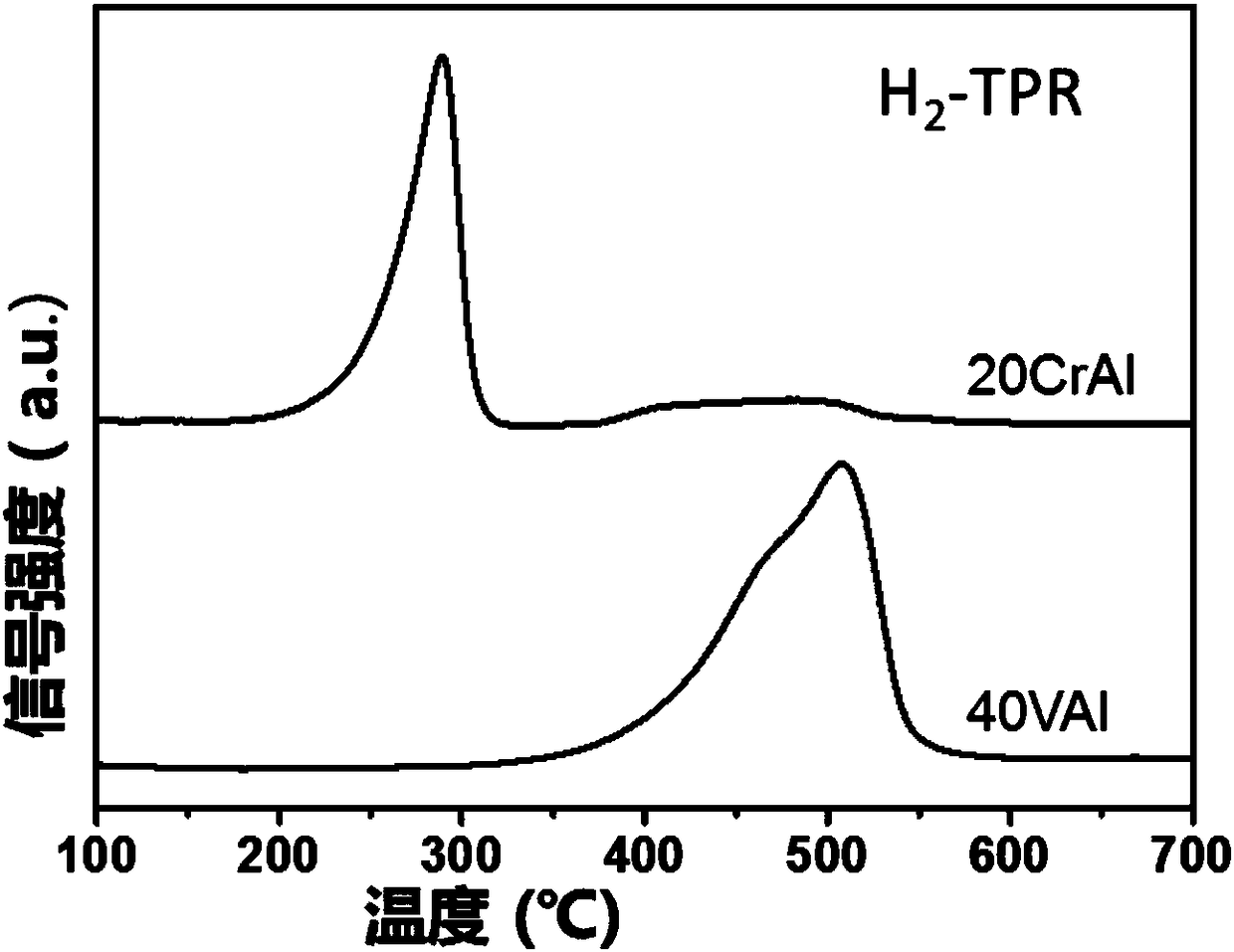

[0028] Step 2, calcining the solid obtained in (1) at 600°C for 2h to obtain VO x / Al 2 o 3 Catalyst (i.e. aluminum oxide loaded with vanadium pentoxide in a high oxidation state);

[0029] Step 3, put VO x / Al 2 o 3 Catalyst powder catalyst tablet molding to make a granular catalyst with a size of 20-40 mesh;

[0030] Step 4, weigh 0.5g of the above-mentioned catalyst and pack it into a fixed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com