Anti-vulcanization LED package silicone material and preparation method thereof

A technology of LED encapsulation and organic silicon, which is applied in the field of anti-vulcanization LED encapsulation organosilicon materials and its preparation, can solve problems affecting the use of LEDs, reducing luminous flux, color temperature drift, etc., and achieves extended service life, excellent anti-vulcanization performance, and parameters reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

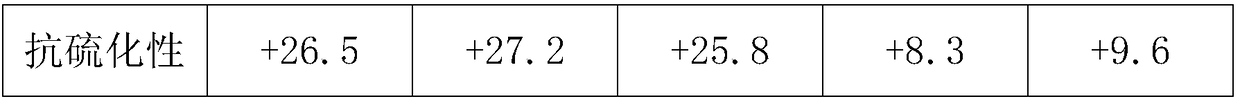

Embodiment 1

[0021] An anti-vulcanization LED encapsulation organosilicon material proposed by the present invention comprises the following raw materials in parts by weight: 60 parts of hexamethyldisiloxane, 45 parts of octamethylcyclotetrasiloxane, bis(dimethylsilane) tetrasiloxane 30 parts of phenylcyclotetrasiloxane, 6 parts of 1,1,3,3-tetramethyl-1,3-divinyldisiloxane, 0.05 parts of Karstedt catalyst, 2,5-dimethyl-2 , 0.8 parts of 5-bis(tert-butylperoxy)hexane, 0.3 parts of tetramethylthiuram disulfide, and 1 part of low-hydrogen silicone oil.

[0022] Its preparation method comprises the following steps:

[0023] S1. According to 60 parts of hexamethyldisiloxane, 45 parts of octamethylcyclotetrasiloxane, 30 parts of bis(dimethylsilane)tetraphenylcyclotetrasiloxane, 1,1,3,3- 6 parts of tetramethyl-1,3-divinyldisiloxane, 0.05 parts of Karstedt catalyst, 0.8 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, di 0.3 parts of tetramethylthiuram sulfide, 1 part of low-hydrogen silico...

Embodiment 2

[0029] An anti-vulcanization LED encapsulation organosilicon material proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of hexamethyldisiloxane, 37.5 parts of octamethylcyclotetrasiloxane, bis(dimethylsilane) tetra 25 parts of phenylcyclotetrasiloxane, 5 parts of 1,1,3,3-tetramethyl-1,3-divinyldisiloxane, 0.08 parts of Karstedt catalyst, 2,5-dimethyl-2 , 0.6 parts of 5-bis(tert-butylperoxy)hexane, 0.4 parts of tetramethylthiuram disulfide, and 0.8 parts of low-hydrogen silicone oil.

[0030] Its preparation method comprises the following steps:

[0031] S1. According to 50 parts of hexamethyldisiloxane, 37.5 parts of octamethylcyclotetrasiloxane, 25 parts of bis(dimethylsilane)tetraphenylcyclotetrasiloxane, 1,1,3,3- 5 parts of tetramethyl-1,3-divinyldisiloxane, 0.08 parts of Karstedt catalyst, 0.6 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, di Prepare 0.4 part of tetramethylthiuram sulfide and 0.8 part of low-hydr...

Embodiment 3

[0037] An anti-vulcanization LED encapsulating organosilicon material proposed by the present invention comprises the following raw materials in parts by weight: 40 parts of hexamethyldisiloxane, 30 parts of octamethylcyclotetrasiloxane, bis(dimethylsilane) tetrasiloxane 20 parts of phenylcyclotetrasiloxane, 4 parts of 1,1,3,3-tetramethyl-1,3-divinyldisiloxane, 0.1 part of Karstedt catalyst, 2,5-dimethyl-2 , 0.5 parts of 5-bis(tert-butylperoxy)hexane, 0.5 parts of tetramethylthiuram disulfide, and 0.5 parts of low-hydrogen silicone oil.

[0038]Its preparation method comprises the following steps:

[0039] S1. According to 40 parts of hexamethyldisiloxane, 30 parts of octamethylcyclotetrasiloxane, 20 parts of bis(dimethylsilane)tetraphenylcyclotetrasiloxane, 1,1,3,3- 4 parts of tetramethyl-1,3-divinyldisiloxane, 0.1 part of Karstedt catalyst, 0.5 part of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, di 0.5 part of tetramethylthiuram sulfide and 0.5 part of low hydrogen-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com