Waterborne anti-corrosion ethylene-propylene emulsion coating

An ethylene-propylene emulsion and anti-corrosion technology, which is applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor water resistance of polyvinyl acetate coatings, and prevent marine organisms from attaching and growing. Long life, good inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

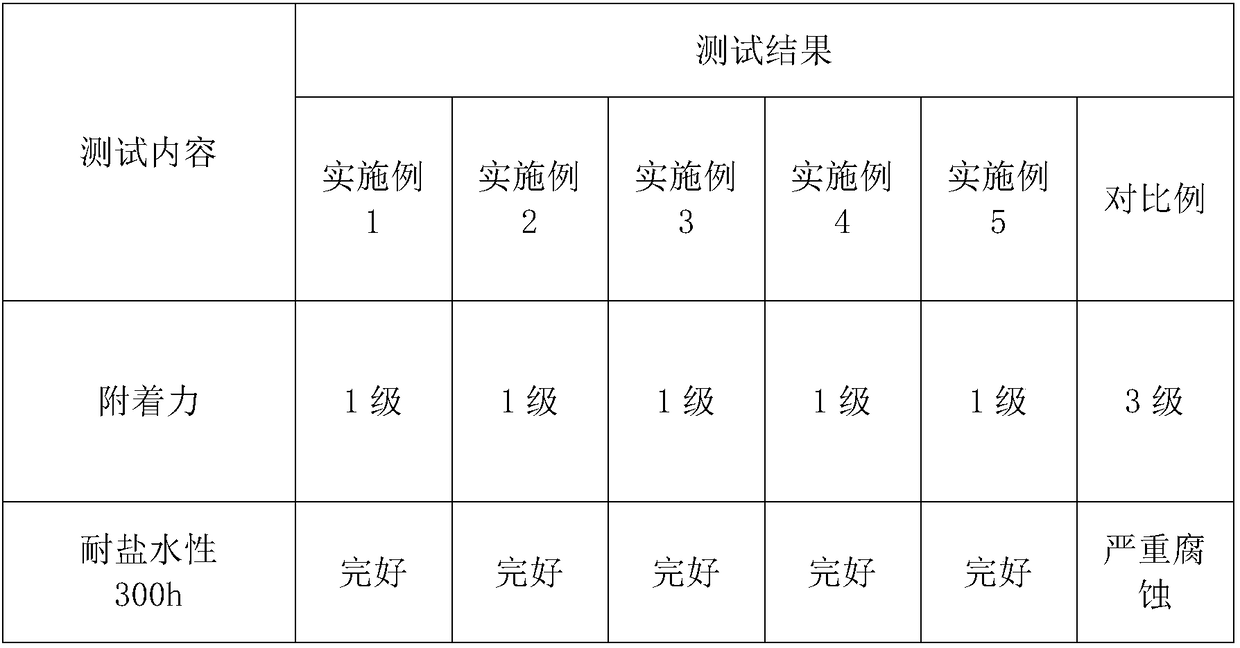

Examples

Embodiment 1

[0030] A water-based anti-corrosion ethylene-propylene emulsion coating, in parts by weight, comprises the following components:

[0031] 100 parts of modified ethylene-propylene emulsion, 16 parts of mica iron oxide, 10 parts of silica, 5 parts of polyethylene glycol-400, 3 parts of adhesion promoter, 4 parts of dipentene, 1 part of polyacrylic acid, carboxymethyl 5 parts of the mixture of cellulose and hydroxypropyl methylcellulose, 2 parts of 2,6-di-tert-butyl-p-cresol, and 30 parts of water;

[0032] The solid content of the modified ethylene-propylene emulsion is 65%;

[0033] The preparation method of described modified ethylene-propylene emulsion, comprises the following steps:

[0034] (1) The nano-TiO 2 The powder was dispersed in the aqueous solution of dodecyl polyglycoside, ultrasonically dispersed for 45 minutes, then added sodium polyacrylate, stirred at 600 rpm for 2 hours, and then dried to obtain modified nano-TiO 2 powder;

[0035] (2) Disperse vinyl acet...

Embodiment 2

[0041] A water-based anti-corrosion ethylene-propylene emulsion coating, in parts by weight, comprises the following components:

[0042] 100 parts of modified ethylene-propylene emulsion, 23 parts of mica iron oxide, 15 parts of silica, 9 parts of polyethylene glycol-400, 5 parts of adhesion promoter, 7 parts of dipentene, 2 parts of polyacrylic acid, carboxymethyl 9 parts of the mixture of cellulose and hydroxypropyl methylcellulose, 5 parts of 2,6-di-tert-butyl-p-cresol, and 40 parts of water;

[0043] The solid content of the modified ethylene-propylene emulsion is 65%;

[0044] The preparation method of described modified ethylene-propylene emulsion, comprises the following steps:

[0045] (1) The nano-TiO 2 The powder was dispersed in an aqueous solution of dodecyl polyglycoside, and ultrasonically dispersed for 60 minutes, then sodium polyacrylate was added to it, stirred at a speed of 800 rpm for 3 hours, and then dried to obtain modified nano-TiO 2 powder;

[0046...

Embodiment 3

[0052] A water-based anti-corrosion ethylene-propylene emulsion coating, in parts by weight, comprises the following components:

[0053] 100 parts of modified ethylene-propylene emulsion, 16 parts of mica iron oxide, 15 parts of silica, 5 parts of polyethylene glycol-400, 5 parts of adhesion promoter, 4 parts of dipentene, 2 parts of polyacrylic acid, carboxymethyl 5 parts of the mixture of cellulose and hydroxypropyl methylcellulose, 5 parts of 2,6-di-tert-butyl-p-cresol, and 30 parts of water;

[0054] The solid content of the modified ethylene-propylene emulsion is 65%;

[0055] The preparation method of described modified ethylene-propylene emulsion, comprises the following steps:

[0056] (1) The nano-TiO 2 The powder was dispersed in an aqueous solution of dodecyl polyglycoside, ultrasonically dispersed for 45 minutes, then sodium polyacrylate was added to it, stirred at a speed of 800 rpm for 2 hours, and then dried to obtain modified nano-TiO 2 powder;

[0057] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com