A variable rate self-circulation ozone electrolysis preparation device

A preparation device and self-circulation technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of deflagration, waste of energy, cost surge, etc., and achieve the effect of high efficiency, high electrolysis efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

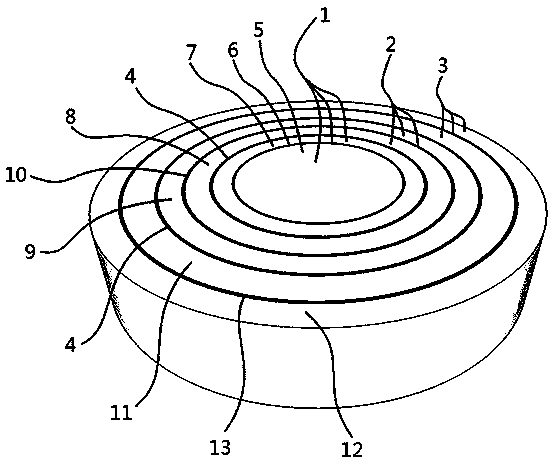

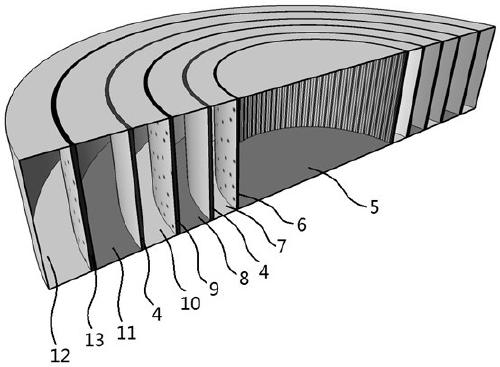

[0038] A variable-rate self-circulating ozone electrolysis preparation device, including a first electrolytic generator group 1, a second electrolytic generator group 2, and a third electrolytic generator group 3, all of which are annular, and the first electrolytic generator group Group 1, the second electrolytic generator group 2, and the third electrolytic generator group 3 are arranged in concentric circles, the first electrolytic generator group 1 is located at the inner center of the concentric circle, and the second electrolytic generator group 2 is surrounded in a ring shape. The periphery of the first electrolytic generator group 1, the third electrolytic generator group 3 is annularly surrounded on the periphery of the second electrolytic generator group 2; the first electrolytic generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com