Methods for preparing CuO/rGO@PNIPAm (poly(N-isopropylacrylamide)) electrode and structuring non-enzyme glucose sensor

A glucose sensor, glucose technology, applied in instruments, scientific instruments, material analysis through electromagnetic means, etc., can solve the problems of yield limitation, low synthesis steps, etc., and achieve the degree of easy compounding, low energy consumption, and significant temperature switch effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

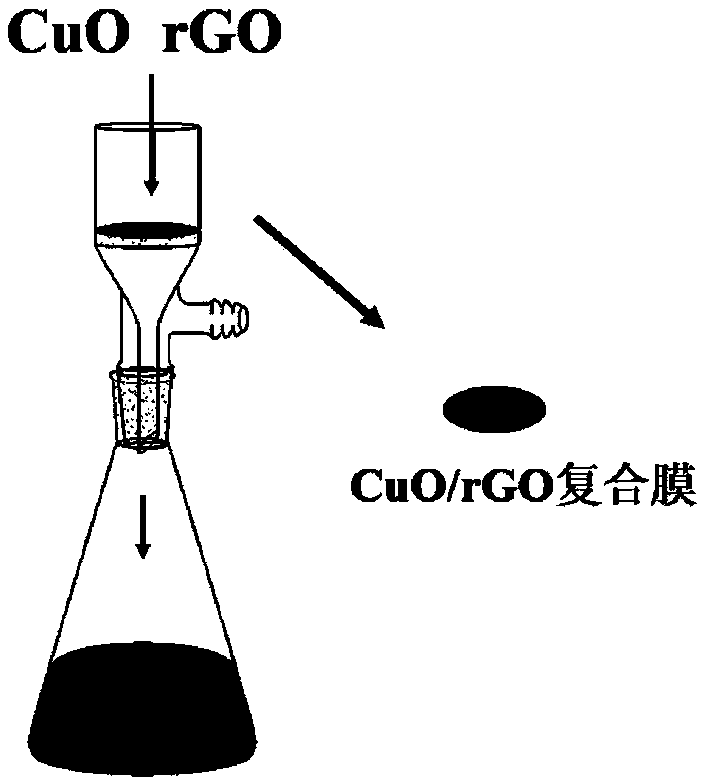

[0027] a) 5g porous CuO and 5g graphene oxide were prepared into a uniformly dispersed suspension, and a CuO / rGO composite film was prepared by suction filtration with a thickness of 10 μm-30 μm.

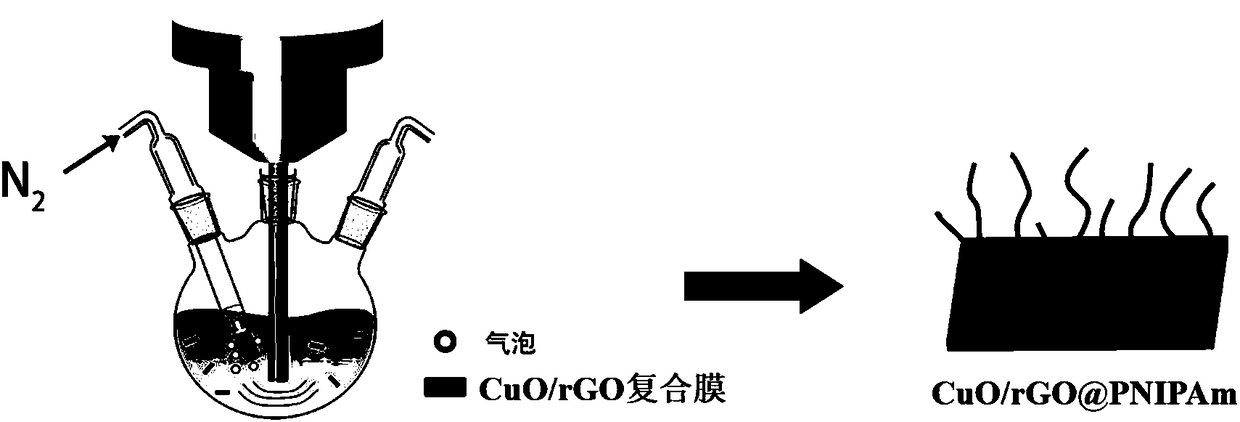

[0028] b) Place the CuO / rGO composite film in 1g / L NIPAm monomer aqueous solution, and carry out plug-in reaction by selecting an ultrasonic horn with an ultrasonic frequency of 20kHz, and the ultrasonic power is 200W. The CuO / rGO@PNIPAm composite film was prepared as a temperature-responsive flexible electrode by ultrasonic-intermittent (N2 gas) circulation mode for polymerization reaction and cumulative ultrasonic irradiation for 1 h.

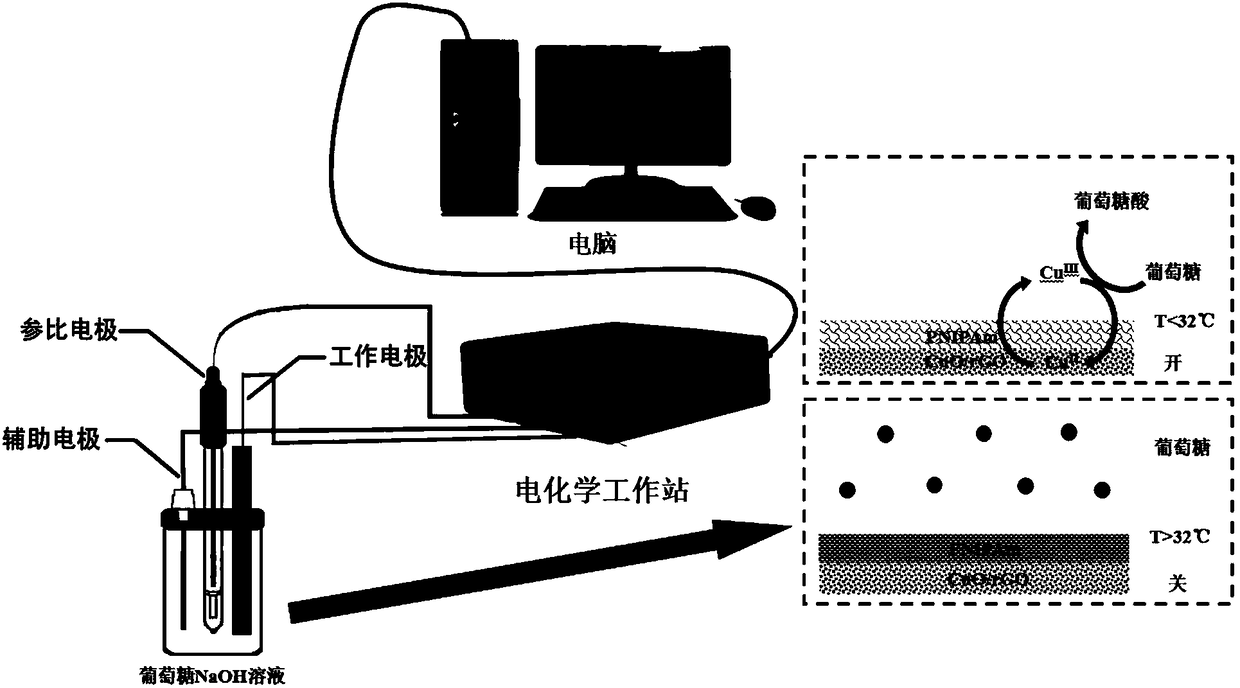

[0029] c) The CuO / rGO@PNIPAm composite film is used as the working electrode, the saturated calomel electrode (SCE) is used as the reference electrode, and the platinum electrode (Pt) is used as the auxiliary electrode. Put the three-electrode system into a weighing bottle filled with 5mM / L glucose NaOH solution, and then put the whole into a water...

Embodiment 2

[0031] a) 5g of porous CuO and 10g of graphene oxide were prepared into a uniformly dispersed suspension, and by suction filtration, a CuO / rGO composite film was prepared with a thickness of 10 μm-30 μm.

[0032] b) Place the CuO / rGO composite film in 1g / L NIPAm monomer aqueous solution, and carry out plug-in reaction by selecting an ultrasonic horn with an ultrasonic frequency of 20kHz, and the ultrasonic power is 200W. Ultrasonic-intermittent (pass N 2 The CuO / rGO@PNIPAm composite film was prepared as a temperature-responsive flexible electrode after the polymerization reaction was carried out in the gas) circulation mode, and the cumulative ultrasonic irradiation was 1 h.

[0033] c) The CuO / rGO@PNIPAm composite film is used as the working electrode, the saturated calomel electrode (SCE) is used as the reference electrode, and the platinum electrode (Pt) is used as the auxiliary electrode. Put the three-electrode system into a weighing bottle filled with 5mM / L glucose NaOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com