High-quality attapulgite oil decolorizing agent

A technology of attapulgite and decolorizing agent, applied in the field of attapulgite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

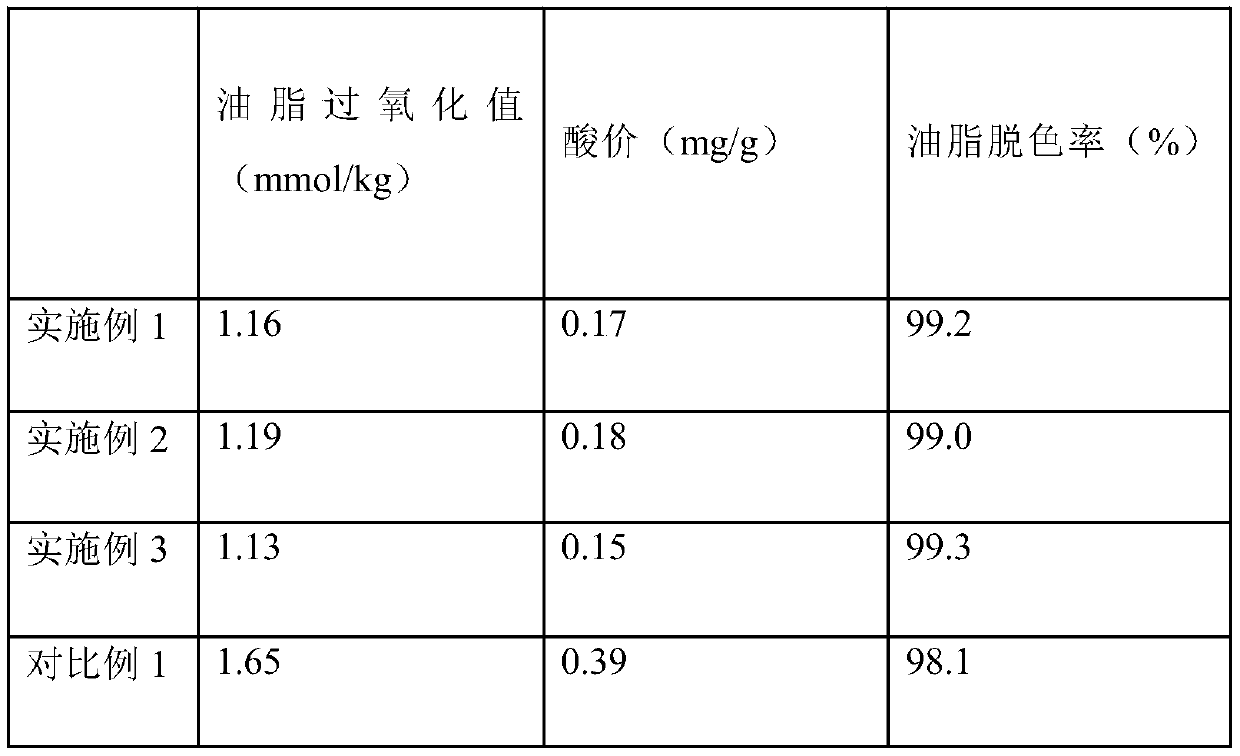

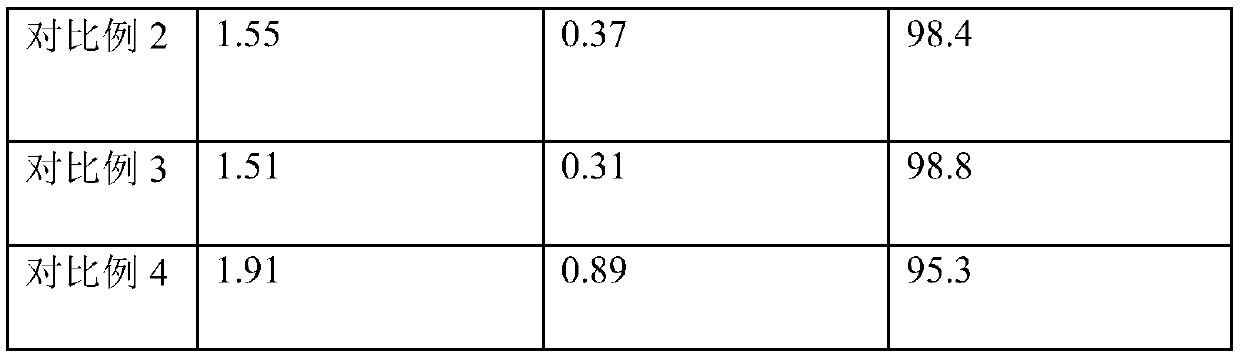

Examples

Embodiment 1

[0026] The invention provides a high-quality attapulgite oil decoloring agent. The oil decolorizing agent is compounded by modified attapulgite, gelatinized modified starch, and crosslinking agent. The modified attapulgite, gelatinized modified starch, and crosslinking agent The mass ratio of substances is 80:9:2;

[0027] The preparation method of high-quality attapulgite oil decolorizer includes the following steps:

[0028] Step 1: Add the modified attapulgite to the ethanol medium, and then send it to the magnetic stirrer for pre-dispersion. The pre-dispersion speed is 300r / min, the pre-dispersion time is 10min, and the stirring temperature is 60°C;

[0029] The preparation method of modified attapulgite is:

[0030] S1: Put the attapulgite in clean water for ultrasonic cleaning for 10 minutes, and then air-dry to a surface moisture content of 3%, and then add it to the reaction tank for activation treatment with phosphoric acid at a speed of 100r / min and an activation time of 20m...

Embodiment 2

[0038] The invention provides a high-quality attapulgite oil decoloring agent. The oil decolorizing agent is compounded by modified attapulgite, gelatinized modified starch, and crosslinking agent. The modified attapulgite, gelatinized modified starch, and crosslinking agent The mass ratio of substances is 90:14:5;

[0039] The preparation method of high-quality attapulgite oil decolorizer includes the following steps:

[0040] Step 1: Add the modified attapulgite to the ethanol medium, and then send it to the magnetic stirrer for pre-dispersion. The pre-dispersion speed is 400r / min, the pre-dispersion time is 20min, and the stirring temperature is 70°C;

[0041] The preparation method of modified attapulgite is:

[0042] S1: Put the attapulgite into clean water and ultrasonically clean for 20 minutes, then air-dry to the surface moisture content of 7%, then add it to the reaction tank and firstly activate it with phosphoric acid. The activation speed is 200r / min and the activation ti...

Embodiment 3

[0050] The invention provides a high-quality attapulgite oil decoloring agent. The oil decolorizing agent is compounded by modified attapulgite, gelatinized modified starch, and crosslinking agent. The modified attapulgite, gelatinized modified starch, and crosslinking agent The mass ratio of substances is 85:11.5:2.5;

[0051] The preparation method of high-quality attapulgite oil decolorizer includes the following steps:

[0052] Step 1: Add the modified attapulgite to the ethanol medium, and then send it to the magnetic stirrer for pre-dispersion. The pre-dispersion speed is 350r / min, the pre-dispersion time is 15min, and the stirring temperature is 65°C;

[0053] The preparation method of modified attapulgite is:

[0054] S1: Put the attapulgite in clean water for ultrasonic cleaning for 15 minutes, then air-dry to the surface moisture content of 5%, and then add it to the reaction tank for activation treatment with phosphoric acid at a speed of 150r / min and an activation time of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com