Mosfet with semi-insulating region and its preparation method

A technology of semi-insulating and insulating gate layers, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low avalanche breakdown tolerance of MOSFETs, reduce leakage current, improve UIS robustness, and improve The effect of breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

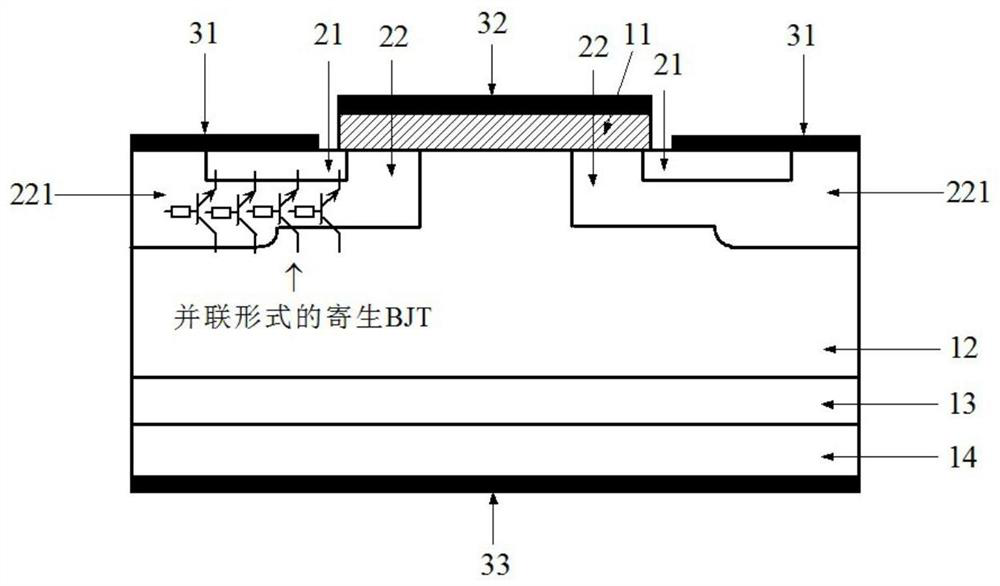

[0046] The MOSFET containing the semi-insulating region of this embodiment, such as image 3 As shown, the semi-insulating region 222 is located below the base region 22 doped with the semiconductor of the first conductivity type and the source region 21 doped with the semiconductor of the second conductivity type arranged side by side. Type semiconductor doped drift layer 12 contacts.

[0047] By setting the semi-insulating region 222, the area where the MOSFET parasitic BJT exists is greatly reduced, thereby greatly reducing the number of parasitic BJT, only a small amount of parasitic BJT still exists in the shallow base area, but due to the great reduction in the number of parasitic BJT , thereby reducing the current in the MOSFET under UIS conditions, limiting the temperature rise, and increasing the avalanche breakdown time of the MOSFET from the theoretical 8 microseconds to 38 microseconds, increasing the time integral of the voltage to the current, and improving the a...

Embodiment 2

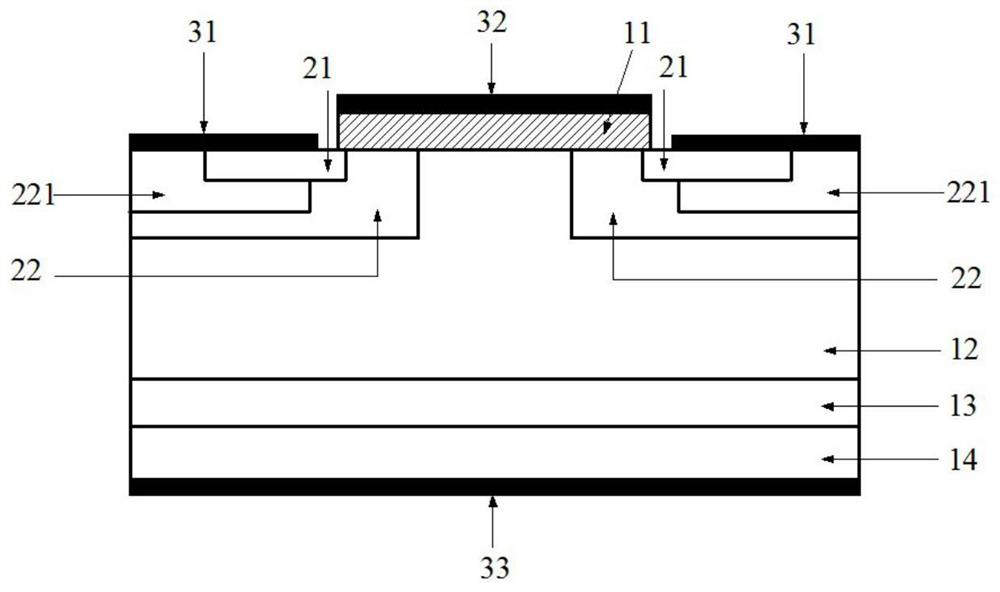

[0052] The MOSFET containing the semi-insulating region of this embodiment, such as image 3 As shown, a further improvement is made on the basis of Embodiment 1. The width of the semi-insulating region 222 is equal to the sum of the widths of the base region 22 doped with the semiconductor of the first conductivity type and the source region 21 doped with the semiconductor of the second conductivity type. The width ratio of the base region 22 doped with the first conductivity type to the source region 21 doped with the second conductivity type is 1:1-3. For specific applications, values such as 1:1; 1:2; 1:3; 1:1.5; 1:2.8 can be selected.

[0053] Precisely controlling the effective channel length of the MOSFET does not change due to the introduction of the semi-insulating region 222, ensuring that parameters such as the threshold voltage, on-resistance, transconductance, and output characteristics of the MOSFET do not change due to the introduction of the semi-insulating r...

Embodiment 3

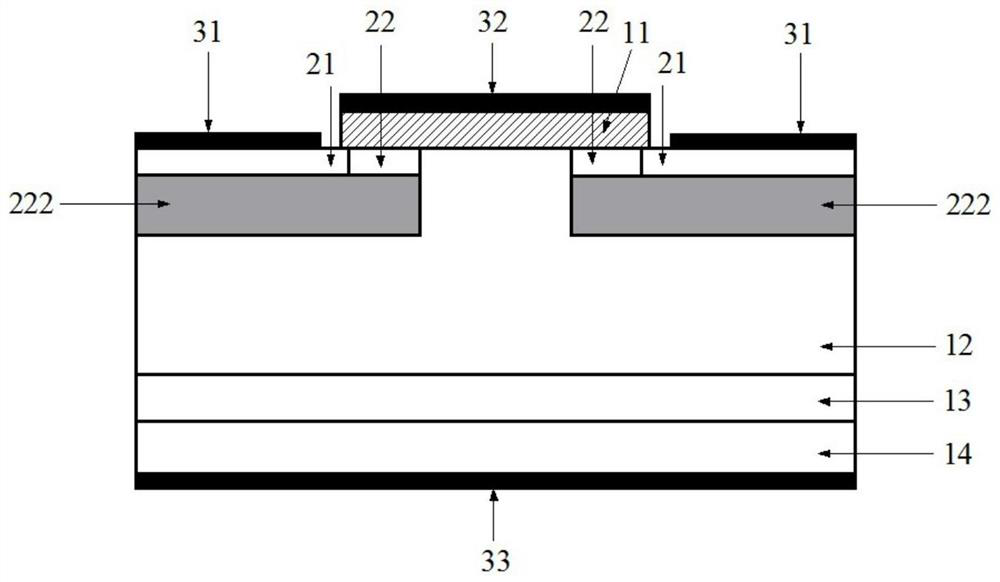

[0055] The MOSFET containing the semi-insulating region of this embodiment, such as image 3 As shown, a further improvement is made on the basis of Embodiments 1 and 2, and the depth of the semiconductor-doped base region 22 is consistent with that of the second conductivity type semiconductor-doped source region 21 . Ensure that the channel carriers are transported smoothly without "crossing the ridge", otherwise the formed abrupt junction will form a potential barrier for the carriers, which is not conducive to the normal operation of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com