Tetrafluoro-borate ion crosslinking hydroxyl polymer binding agent, preparation method thereof, secondary battery and negative electrode and negative paste of secondary battery

A hydroxyl polymer, tetraborate technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode current collector coatings, etc. Adhesion strength and mechanical properties improvement, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

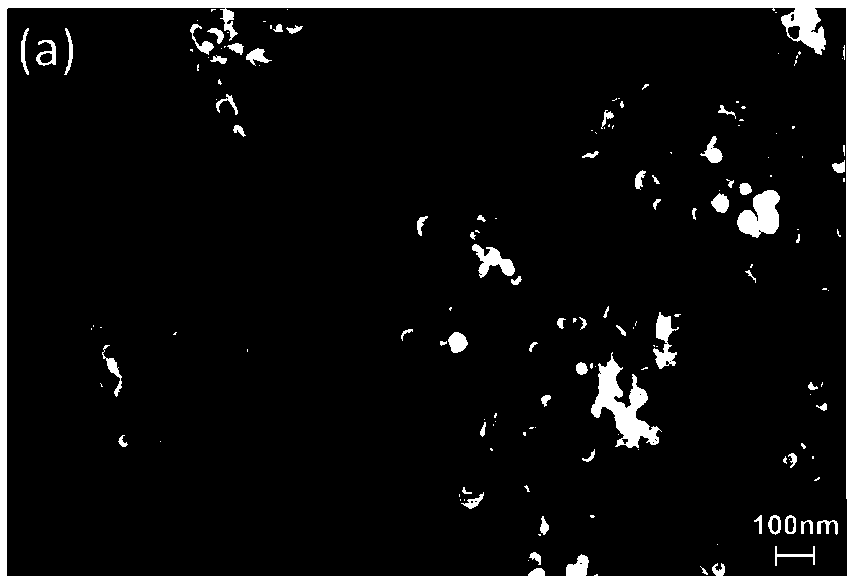

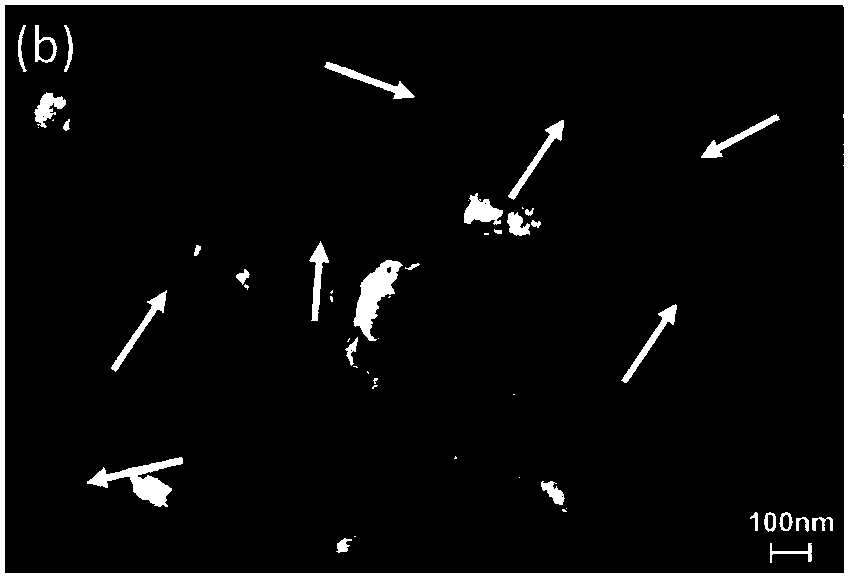

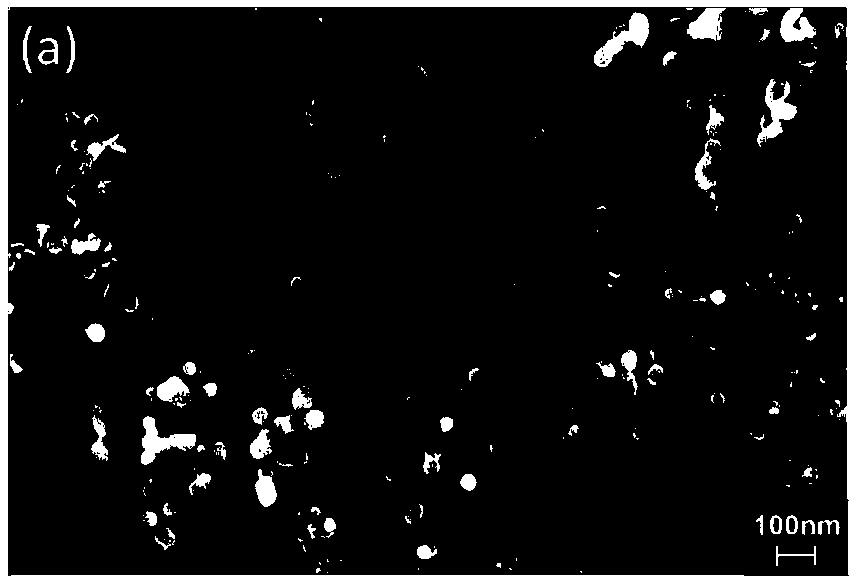

Image

Examples

Embodiment 1

[0043] First, borax and polyvinyl alcohol were dissolved in distilled water to prepare aqueous solutions with mass fractions of 1.0% and 5.0%. Then the borax aqueous solution and the polyvinyl alcohol aqueous solution were mixed, and then heated to 85° C. under the condition of stirring, and kept for 16 hours to form tetraborate ion cross-linked hydroxyl polymer adhesive A1. Wherein, the mass ratio of borax and polyvinyl alcohol is 0.01:1, wherein, the mass percentage of borax is 0.048%, and the mass percentage of polyvinyl alcohol is 4.762%.

[0044] A lithium-ion battery was assembled according to the above method using binder A1 and its electrochemical performance was tested.

Embodiment 2

[0046] The specific preparation method of the tetraborate ion crosslinked hydroxyl polymer adhesive of the present embodiment is the same as the preparation of A1, the difference is that the mass ratio of borax and polyvinyl alcohol is 0.05:1, to obtain adhesive A2, Wherein, the mass percentage of borax is 0.200%, and the mass percentage of polyvinyl alcohol is 4.000%.

[0047] A lithium-ion battery was assembled according to the above method using binder A2 and its electrochemical performance was tested.

Embodiment 3

[0049] The specific preparation method of the tetraborate ion crosslinked hydroxyl polymer adhesive of the present embodiment is the same as the preparation of A1, the difference is that the mass ratio of borax and polyvinyl alcohol is 0.1:1, to obtain adhesive A3, Wherein, the mass percentage of borax is 0.333%, and the mass percentage of polyvinyl alcohol is 3.333%.

[0050] A lithium-ion battery was assembled according to the above method using binder A3 and its electrochemical performance was tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com