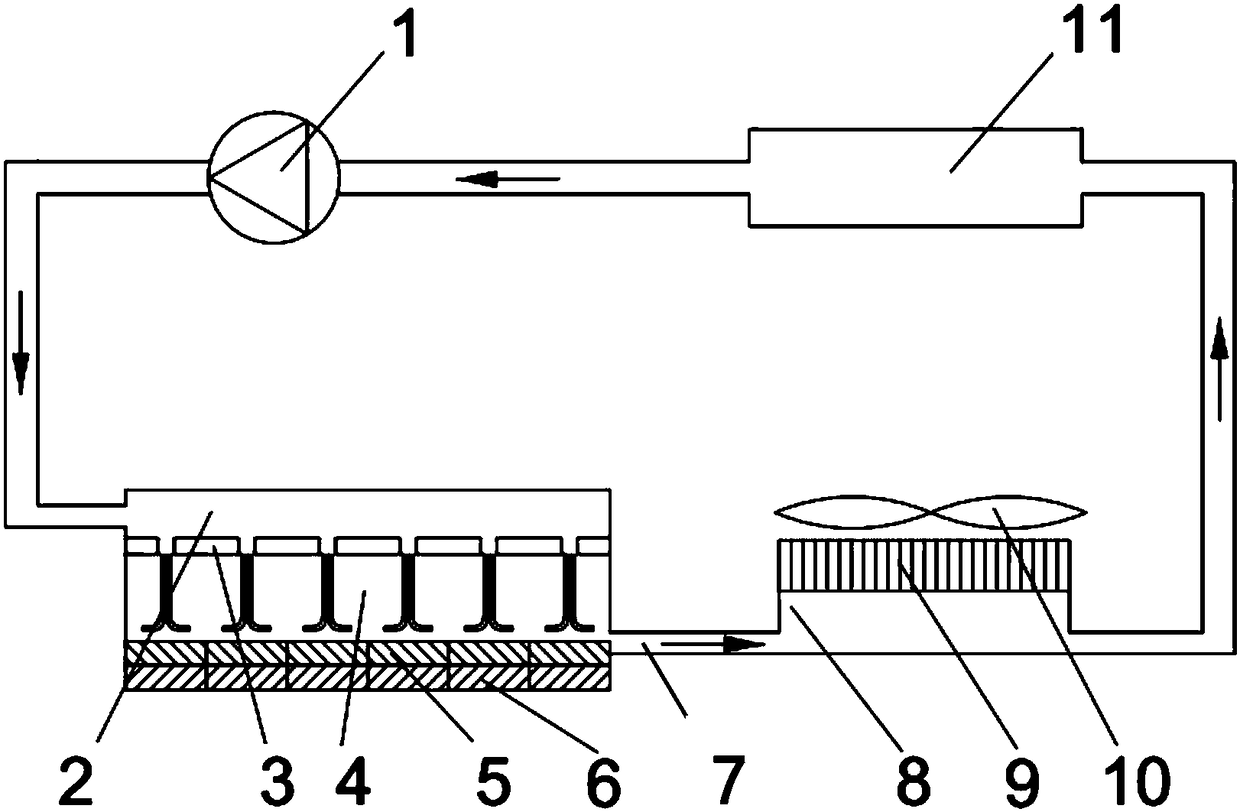

Micro-jet cooling plate for adding porous heat transfer surfaces and manufacturing method of micro-jet cooling plate

A heat transfer surface and micro-spray technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of uniform and uneven temperature distribution of batteries that are difficult to cool instantly, so as to improve battery power generation efficiency and solve uneven distribution Uniform and increase the effect of phase change heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

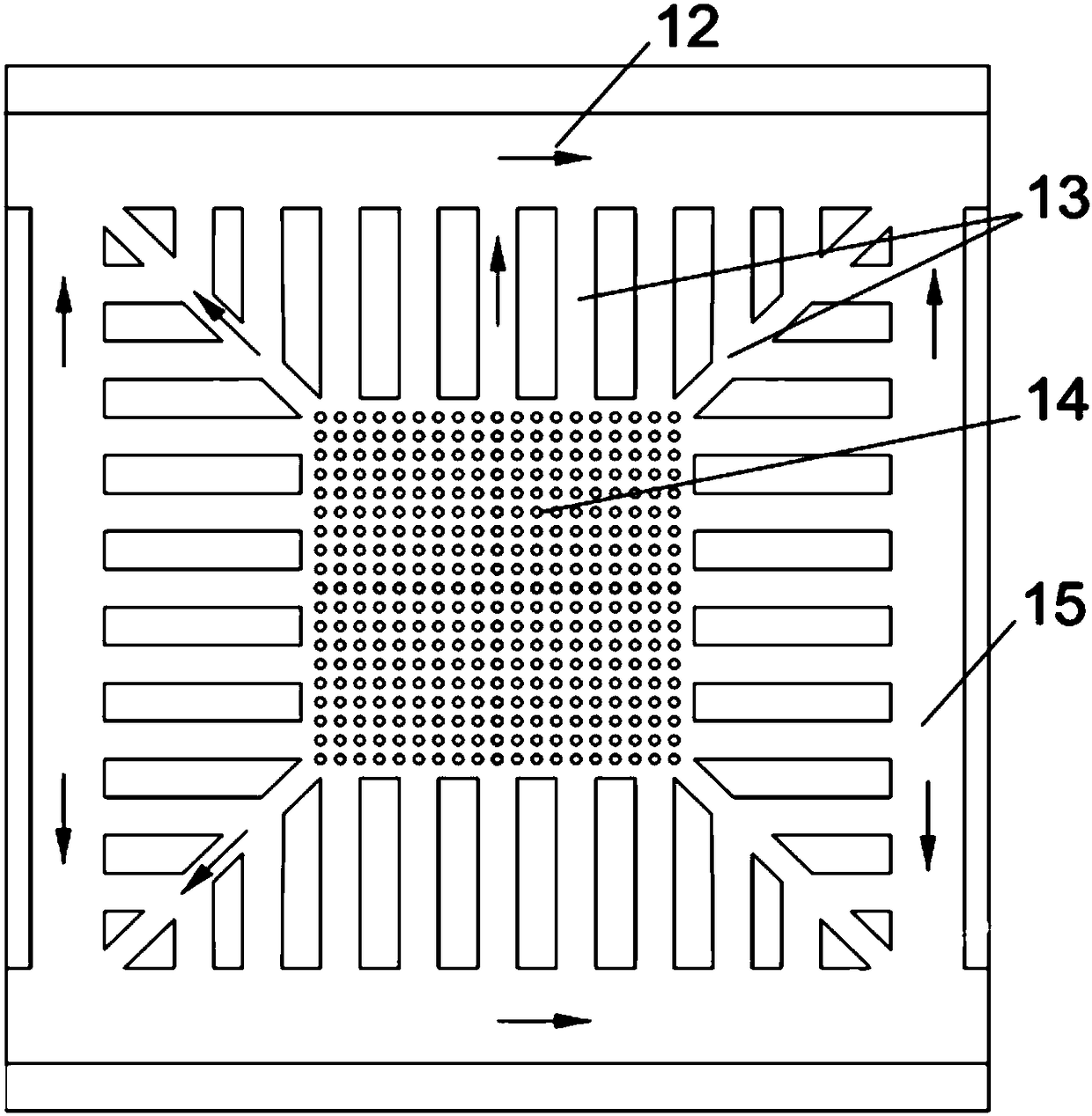

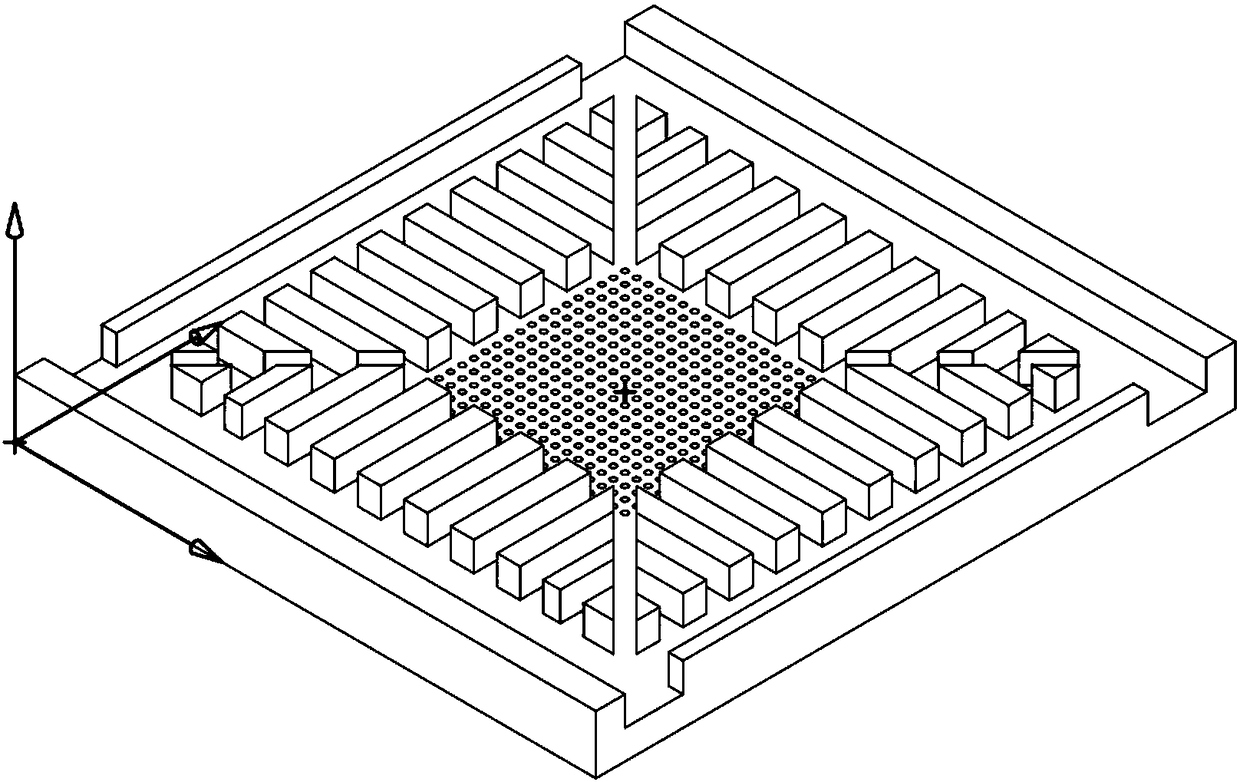

[0025] Such as figure 2 Shown, a kind of micro-jet flow cooling plate that adds porous heat transfer surface, the rectangular working surface of described micro-jet flow cooling plate is centrally provided with the porous super-hydrophilic surface structure 14 that is made up of some evenly distributed small holes, and described Two cooling liquid outlet passages are arranged in parallel at the two opposite sides of the working surface, and a cooling liquid collection passage 15 with both ends connected to the cooling liquid outlet passages is arranged in parallel at the other two opposite sides of the working surface. Several fine channels 13 are evenly connected between the hydrophilic surface structure 14 and the cooling liquid outlet channel and the cooling liquid collection channel 15 . The cooling liquid is sprayed onto the cooling plate with a porous structure by the micro-injector, flows through the evenly distributed fine channels 13, and then collects in the cooling...

Embodiment 2

[0032] A method for manufacturing the micro-jet cooling plate, comprising the steps of:

[0033] 1) Machining the cooling liquid outlet channel, the cooling liquid collecting channel 15 and the fine channel 13 on the surface of the smooth metal substrate by a mechanical processing method of plow cutting and extrusion;

[0034] 2) Prepare a porous super-hydrophilic surface structure14 in the middle region of the metal substrate by particle sintering;

[0035] 3) Performing hydrophobic surface treatment on the bottom surface of the micro-channel 13 by chemical deposition method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation distance | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com