Grape branch picking crushing machine

A pulverizer and pick-up mechanism technology, applied in loaders, mechanical equipment, sugarcane machining and other directions, can solve the problems of grape branches polluting the environment, time-consuming and labor-intensive, etc., and achieve the effects of reducing incineration, reducing pollution, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

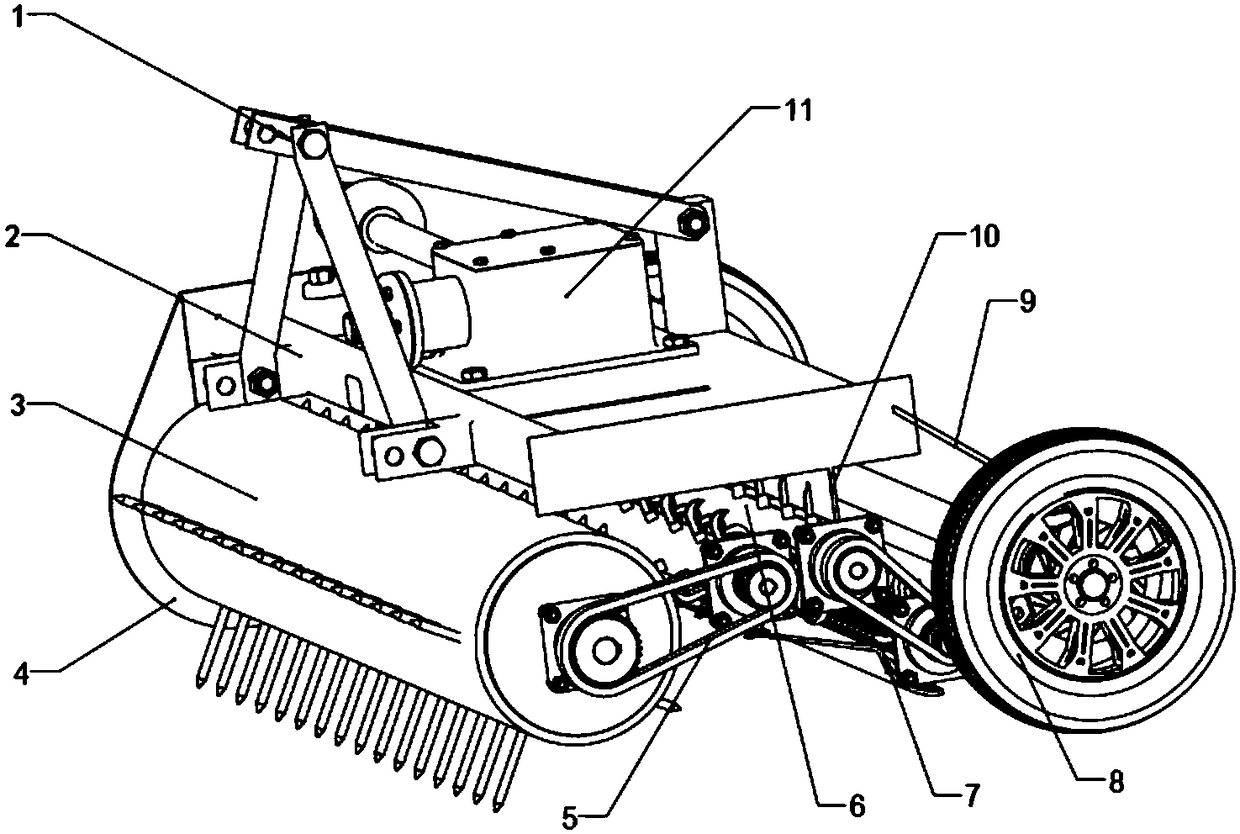

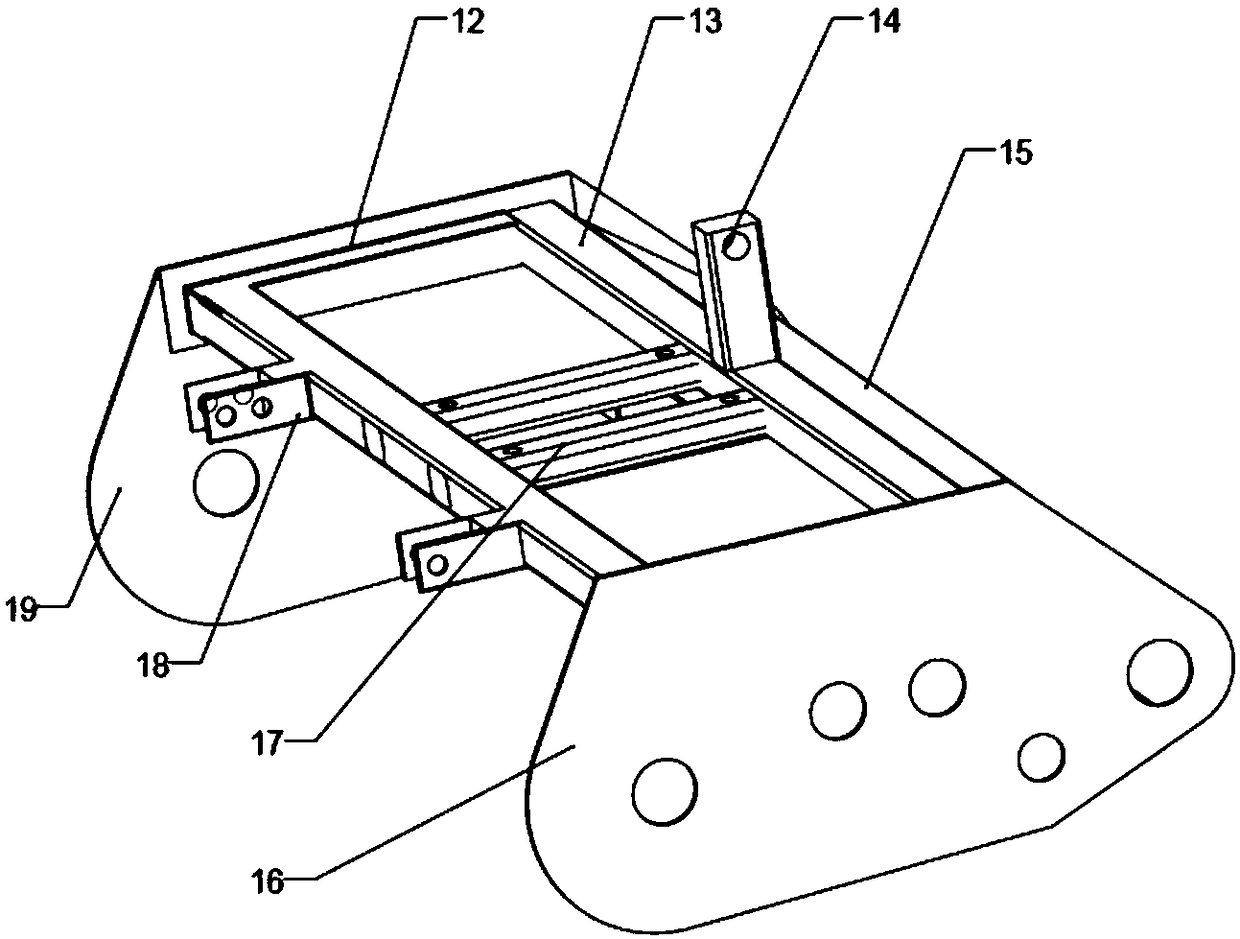

[0039] like figure 1 and figure 2 As shown, the grape branch picking and crushing machine is mainly composed of a suspension device 1, a frame 2, a picking mechanism 3, a side plate 4, a transmission system 5, a cutting mechanism 6, a kneading and cutting mechanism 7, a balance wheel mechanism 8, and a rear cover 9 , baffle plate 10 and gearbox 11 and so on. The frame 2 is welded by square profiles, and includes two longitudinal beams 12, two crossbeams 13, upper tie rod columns 14, gearbox fixing beam 17 and two lower tie rod connecting columns 18. The side panels 4 are fixed on the left and right sides of the frame 2 and include a left side panel 16 and a right side panel 19 .

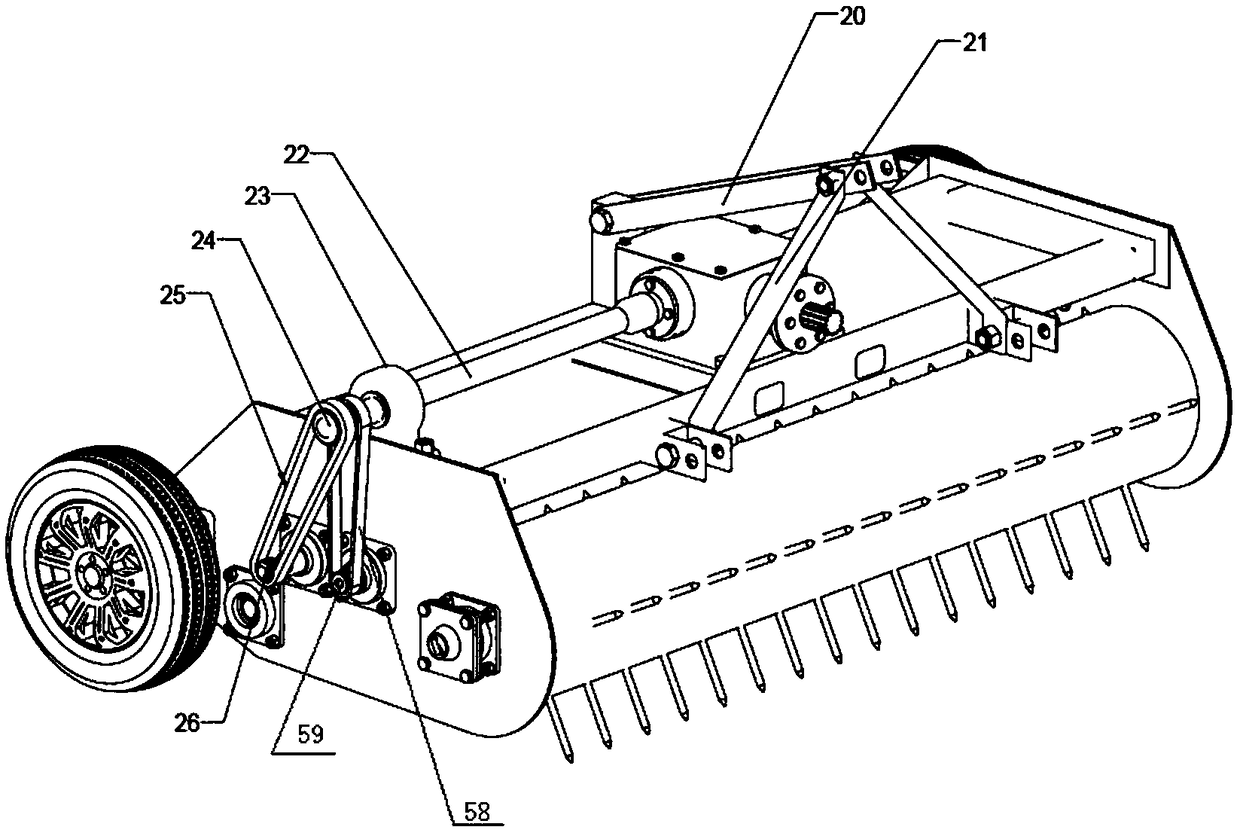

[0040] like image 3 and Figure 4 As shown, the suspension device 1 includes an upper tie rod 20 and two side support rods 21 . Wherein there are two upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com