Method for preparing ultrafine magnesium fluoride

A technology of fine magnesium fluoride and sodium fluoride, applied in the field of preparation of ultra-fine magnesium fluoride, can solve the problem of uneven particle size of MgF2, failure to reach the main content of ultra-fine magnesium fluoride not less than 99%, and difficult washing Filter to remove impurities and other problems, to avoid gelation, reduce reaction supersaturation, and solve the effect of easy gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

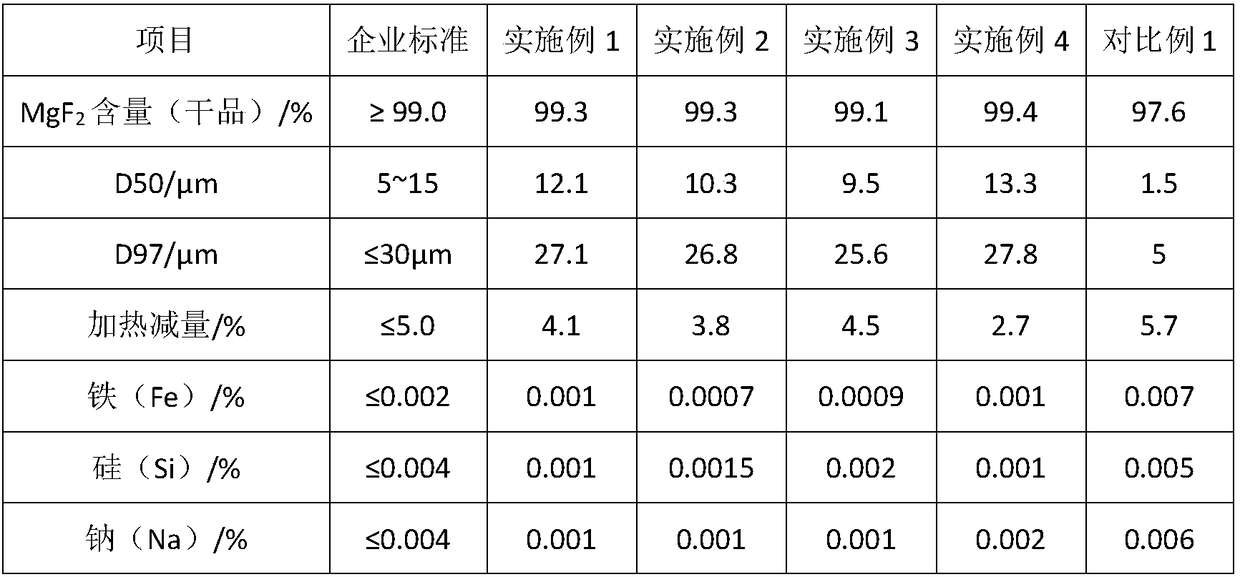

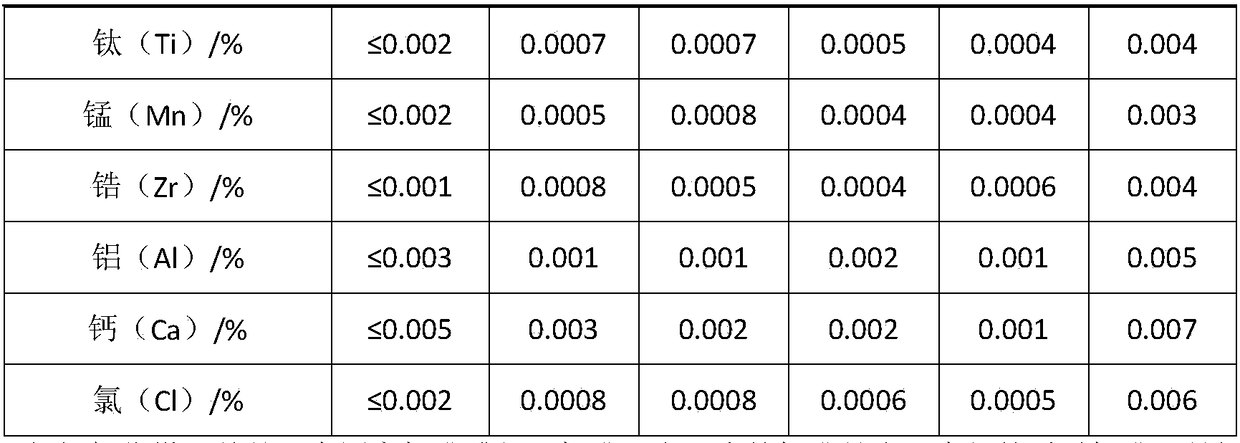

Examples

Embodiment 1

[0023] The preparation method of the present invention comprises the following steps:

[0024] (1) Preparation of saturated sodium fluoride solution: Add 42 g of granular sodium fluoride with a particle size of 0.5 to 0.8 mm into 360 mL of water, place it in a constant temperature water bath at 10°C, and stir until the sodium fluoride solid no longer dissolves, that is, Obtain a saturated sodium fluoride solution, which also contains undissolved sodium fluoride solid;

[0025] (2) Synthetic reaction: in step (1) gained saturated sodium fluoride solution, slowly drip 475g mass fraction into the magnesium chloride solution of 10%, the time of dropping is 1h, stir constantly, control stirring speed 300r / min, after feeding finishes Continue to react for 1 h to obtain a suspension;

[0026] (3) Washing and drying: filter and wash the suspension obtained in step (2), and dry at 70° C. for 9 hours to obtain ultrafine magnesium fluoride powder that is easy to disperse and has uniform...

Embodiment 2

[0028] The preparation method of the present invention comprises the following steps:

[0029] (1) Preparation of saturated sodium fluoride solution: Add 42 g of granular sodium fluoride with a particle size of 0.5 to 0.8 mm into 360 mL of water, place it in a constant temperature water bath at 15°C, and stir until the solid sodium fluoride no longer dissolves, that is, Obtain a saturated sodium fluoride solution, which also contains undissolved sodium fluoride solid;

[0030] (2) Synthetic reaction: Slowly add 316.7g of magnesium chloride solution with a mass fraction of 15% in the saturated sodium fluoride solution obtained in step (1), the time for the addition is 1h, keep stirring, control the stirring speed at 350r / min, and the feeding ends Then continue to react for 2h to obtain a suspension;

[0031] (3) Washing and drying: filter and wash the suspension obtained in step (2), and dry at 80° C. for 8 hours to obtain ultrafine magnesium fluoride powder that is easy to di...

Embodiment 3

[0033] The preparation method of the present invention comprises the following steps:

[0034] (1) Preparation of saturated sodium fluoride solution: Add 42 g of granular sodium fluoride with a particle size of 0.2 to 0.5 mm into 324 mL of water, place it in a constant temperature water bath at 20°C, and stir until the solid sodium fluoride no longer dissolves, that is, Obtain a saturated sodium fluoride solution, which also contains undissolved sodium fluoride solid;

[0035] (2) Synthetic reaction: Slowly add 237.5g of magnesium chloride solution with a mass fraction of 20% in the saturated sodium fluoride solution obtained in step (1), the time for the addition is 1h, keep stirring, control the stirring speed at 300r / min, and the feeding ends Then continue to react for 1 h to obtain a suspension;

[0036] (3) Washing and drying: filter and wash the suspension obtained in step (2), and dry at 65° C. for 10 hours to obtain ultrafine magnesium fluoride powder that is easy to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com