A polyetheretherketone 3D printing material and 3D printing molding method thereof

A 3D printing and polyether ether ketone technology, applied in the field of 3D printing, can solve the problems of poor uniformity of 3D printing materials and difficulty in enhancing the effect, so as to solve the stacking of printing materials, facilitate large-scale mass production, and improve the coefficient of friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

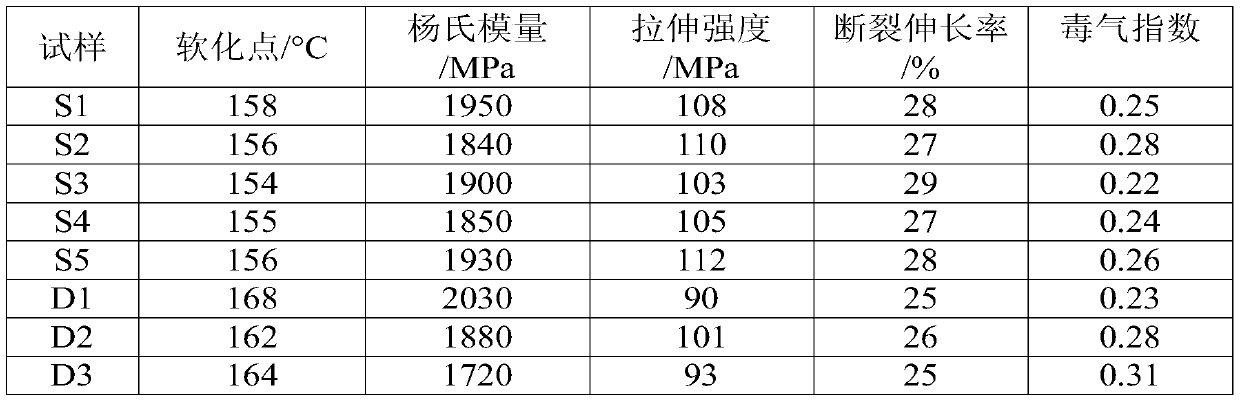

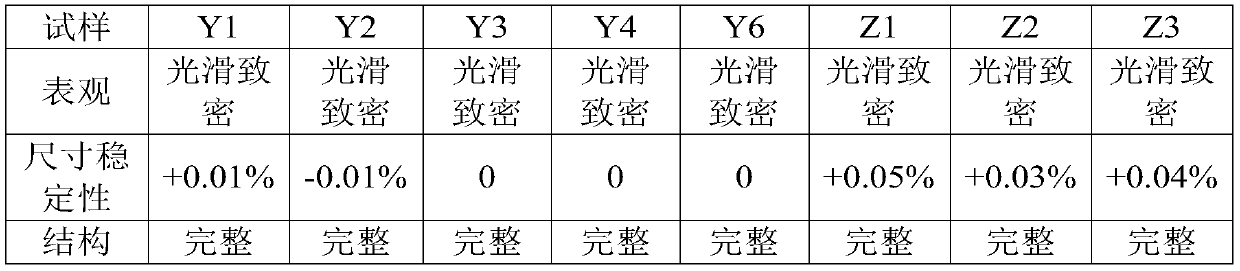

Examples

Embodiment 1

[0032] A polyetheretherketone 3D printing material

[0033] Recipe: polyetheretherketone 1000g, methylenebisacrylamide 100g, polyetherimide 20g

[0034] The preparation method comprises the following steps:

[0035] Step 1, dissolving 1000g of polyetheretherketone in 1000mL of concentrated sulfuric acid to obtain sulfonated polyetheretherketone;

[0036] Step II, dissolving 100 g of methylenebisacrylamide in water to obtain a methylenebisacrylamide solution with a concentration of 0.1 mol / L;

[0037] Step III, mixing the sulfonated polyether ether ketone obtained in step I with the methylenebisacrylamide solution obtained in step II to obtain PEEK-MBA;

[0038] Step IV: Dry the PEEK-MBA obtained in Step III at a temperature of 120°C for 30 minutes, then mix it with 20g of polyetherimide, and extrude it with a twin-screw extruder at a temperature of 380°C. Screw speed is 300rpm, obtains PEEK-MBA-PEI blend;

[0039] Step V, adding the PEEK-MBA-PEI blend obtained in Step IV i...

Embodiment 2

[0043] A polyetheretherketone 3D printing material

[0044] Recipe: 1000g polyetheretherketone, 1000g methylenebisacrylamide, 100g polyetherimide

[0045] The preparation method comprises the following steps:

[0046] Step 1, dissolving 1000g of polyetheretherketone in 3000mL of concentrated sulfuric acid to obtain sulfonated polyetheretherketone;

[0047] Step II, dissolving 1000g methylenebisacrylamide in water to obtain a methylenebisacrylamide solution with a concentration of 2.0mol / L;

[0048] Step III, mixing the sulfonated polyether ether ketone obtained in step I with the methylenebisacrylamide solution obtained in step II to obtain PEEK-MBA;

[0049] Step IV: Dry the PEEK-MBA obtained in Step III at a temperature of 130°C for 90 minutes, then mix it with 100g of polyetherimide, and extrude it with a twin-screw extruder at a temperature of 390°C. Screw speed is 300rpm, obtains PEEK-MBA-PEI blend;

[0050] Step V, adding the PEEK-MBA-PEI blend obtained in Step IV in...

Embodiment 3

[0054] A polyetheretherketone 3D printing material

[0055] Recipe: 1000g polyetheretherketone, 550g methylenebisacrylamide, 60g polyetherimide

[0056] The preparation method comprises the following steps:

[0057] Step 1, dissolving 1000g of polyetheretherketone in 2000mL of concentrated sulfuric acid to obtain sulfonated polyetheretherketone;

[0058] Step II, dissolving 550g methylenebisacrylamide in water to obtain a methylenebisacrylamide solution with a concentration of 1.1mol / L;

[0059] Step III, mixing the sulfonated polyether ether ketone obtained in step I with the methylenebisacrylamide solution obtained in step II to obtain PEEK-MBA;

[0060] Step IV: Dry the PEEK-MBA obtained in Step III at a temperature of 125°C for 60 minutes, then mix it with 60g of polyetherimide, and extrude it with a twin-screw extruder at a temperature of 385°C. Screw speed is 300rpm, obtains PEEK-MBA-PEI blend;

[0061] Step V, adding the PEEK-MBA-PEI blend obtained in Step IV into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com