Multipurpose axial ball plug-type water hydraulic motor or pump

A multi-action, water-hydraulic technology, applied in the hydraulic field, can solve problems such as difficulty, hydraulic oil pollution, flammability, etc., to achieve the effect of improving strength, prolonging service life, and ensuring effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the above-mentioned content of the invention and the following embodiments, in order to distinguish the parts of components with the same name in each embodiment, “A”, “B” and “C” are respectively added before / after the names of the parts of components with the same name The words "D" and "D" have no special sequence meaning; the number of the following plunger holes is preferably 7 to 11, most preferably 8 or 9. When the number of plunger holes is 8, the cylinder body rotates 360° once, and the ball plug assembly reciprocates 3 times, that is, 3 times of water absorption and 3 times of water discharge; when the number of plunger holes is 9, the cylinder body rotates once 360°, the ball plug assembly reciprocates 4 times, that is, 4 times of water absorption and 4 times of water discharge.

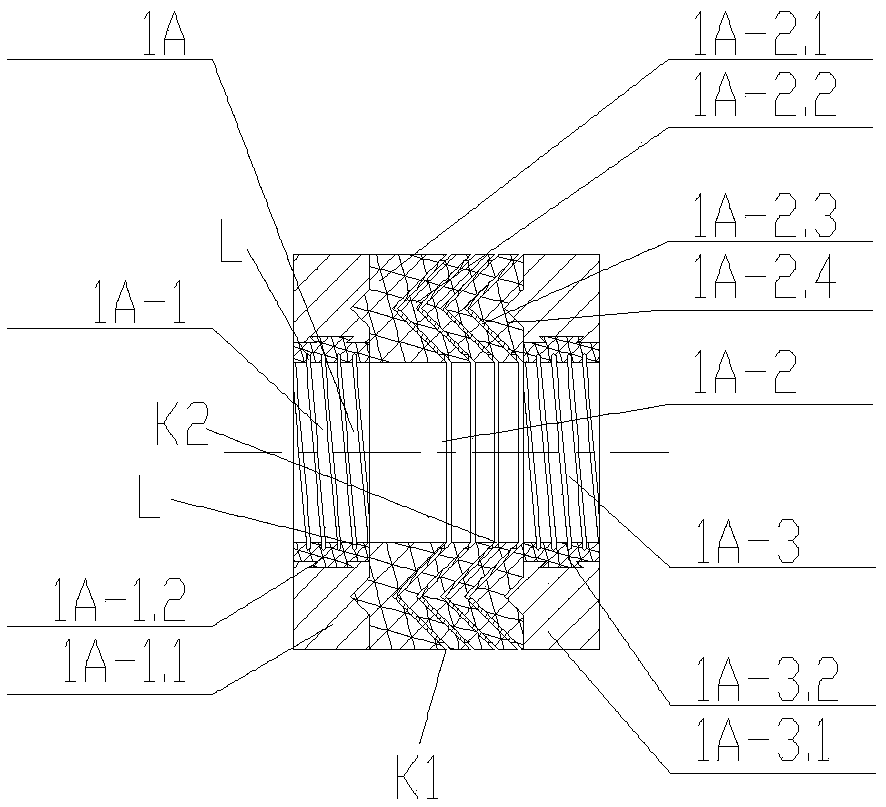

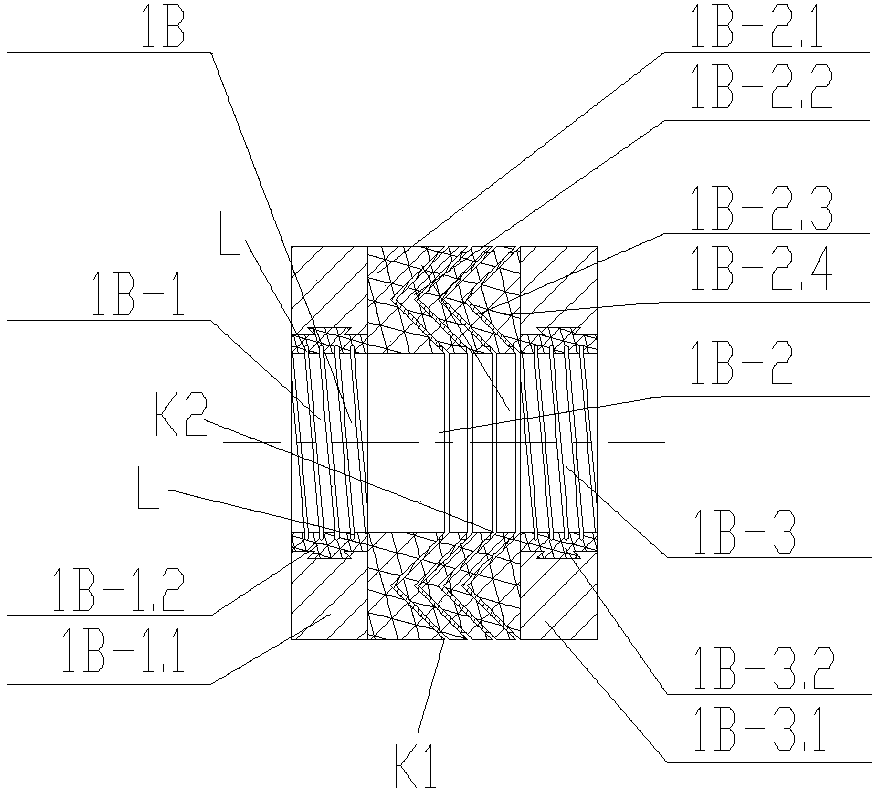

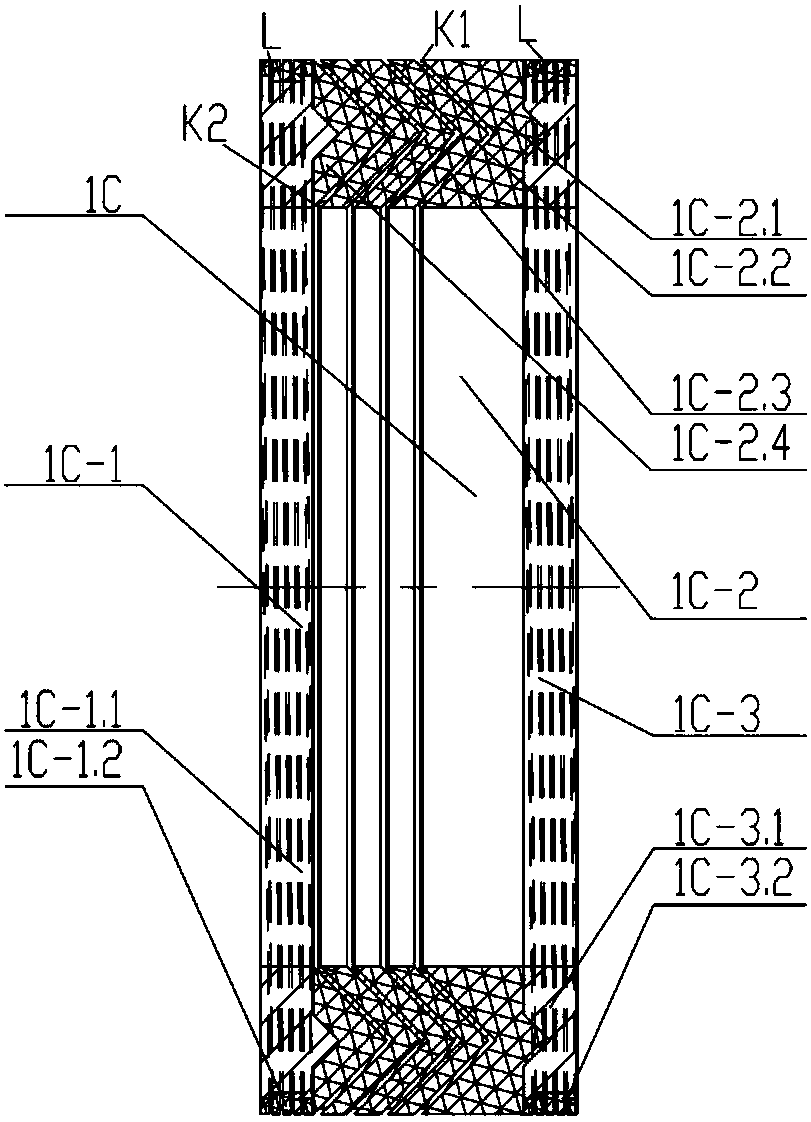

[0043] Embodiment 1 of Multi-acting Axial Ball Plug Water Hydraulic Motor or Pump

[0044] refer to Figure 11a and 11b as well as Figure 12a , 12b , 12c and 12d, the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com