Microcavity array coupled structure for quantum well detector and manufacturing method thereof

A technology of coupling structure and manufacturing method, which is applied in the field of semiconductor photon detectors, can solve problems such as unfavorable device integration, not much improvement in device performance, and inability to realize normal incidence of light, so as to reduce dark current, enhance electric field, and improve Effect of Operating Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

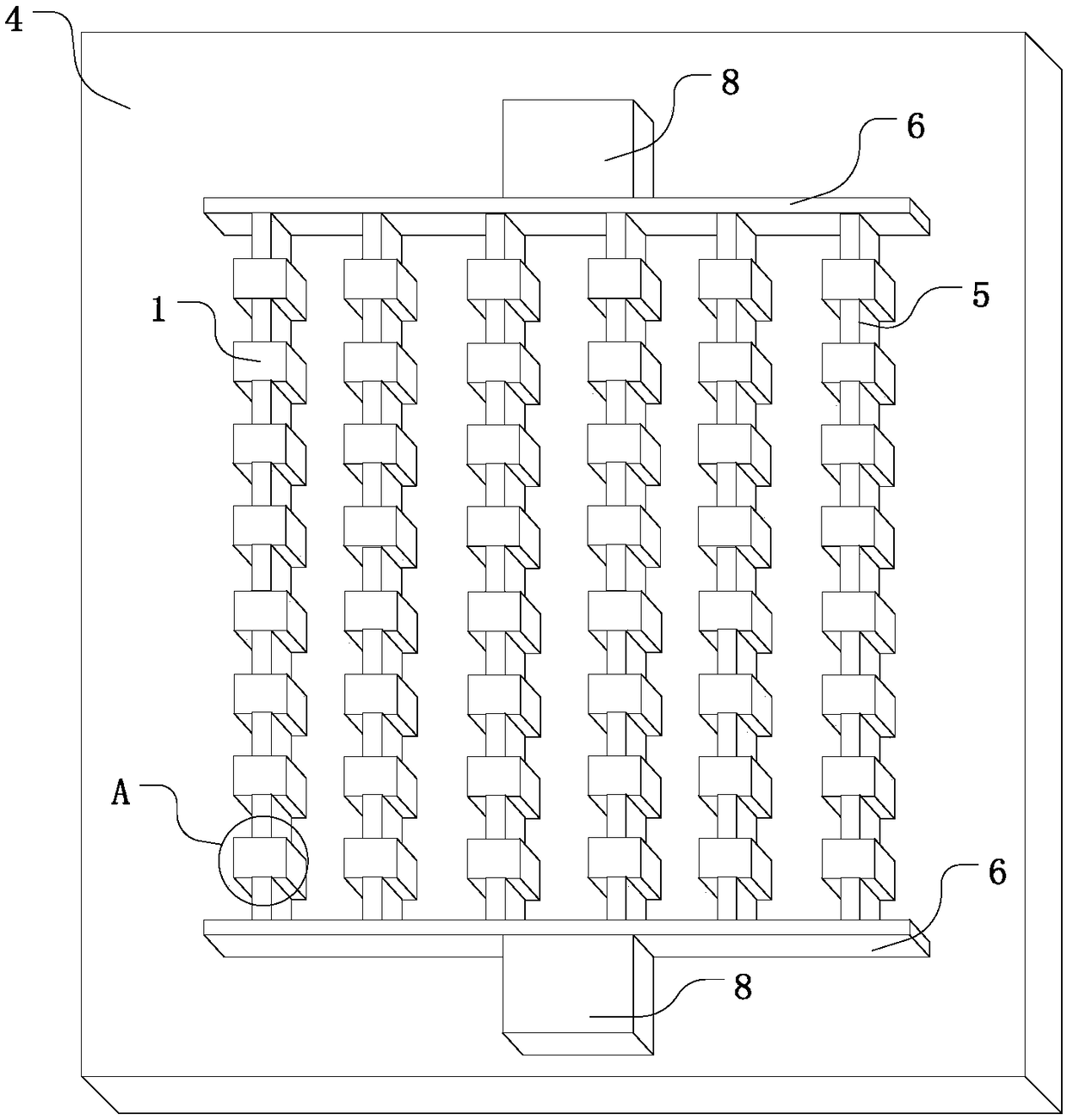

[0042] Such as Figure 2-4 As shown, one of the present invention, that is, a microcavity array coupling structure for a quantum well detector, includes: a plurality of microcavity units 1 distributed in an array and a substrate 7 located below the microcavity unit 1, wherein,

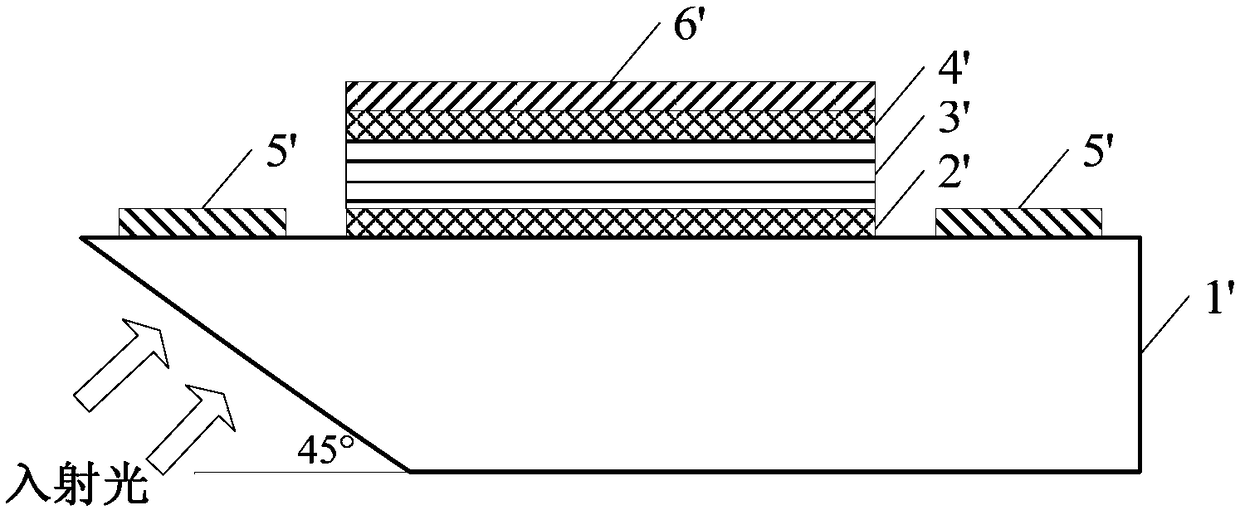

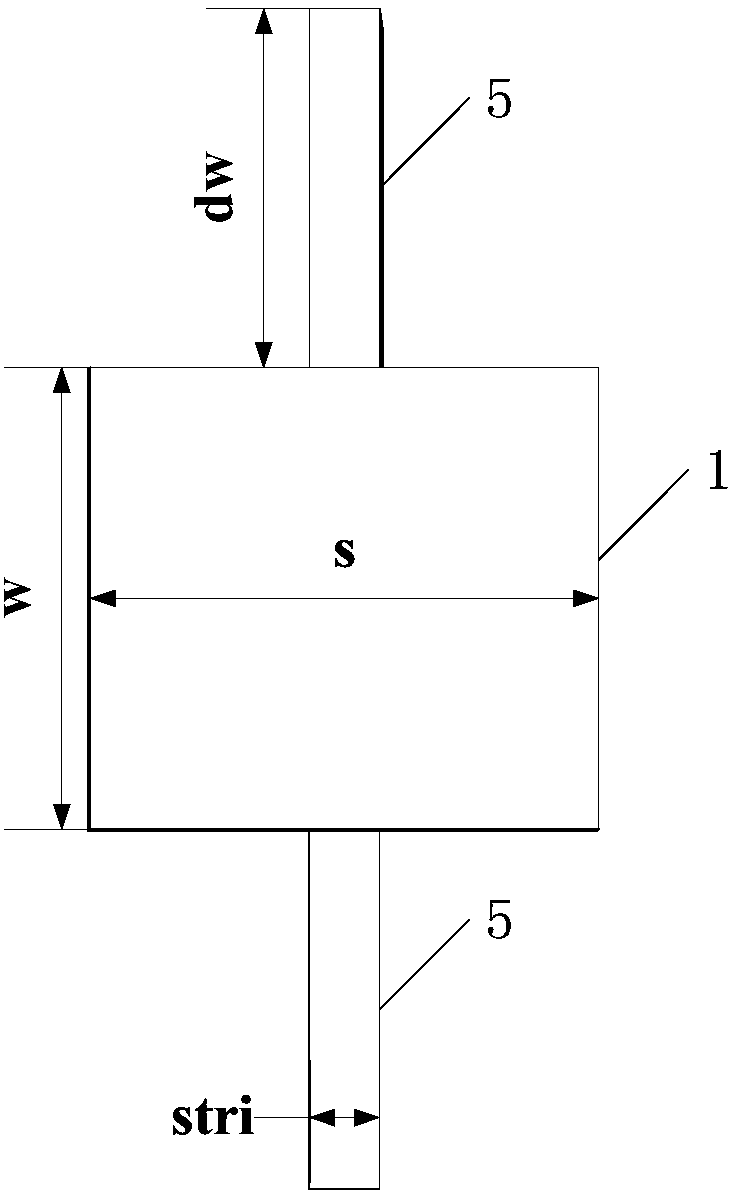

[0043] Each microcavity unit 1 comprises: upper metal electrode 2, and the epitaxial layer 3 (the geometric dimension of epitaxial layer 3 is identical with the geometric dimension of upper metal electrode 2) of the quantum well detector that is arranged on the lower surface of upper metal electrode 2 ), all microcavity units 1 also include a common lower metal electrode plate 4 on which the epitaxial layer 3 for the quantum well detector is arranged, and the lower metal electrode plate 4 is arranged on the upper surface of the substrate 7;

[0044] A plurality of microcav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com