Safe disposal method for charged lithium ion batteries

A technology for safe disposal of lithium-ion batteries, applied in secondary batteries, battery recycling, circuits, etc., can solve problems such as increased cost of recycling waste batteries, achieve centralized collection and treatment, reduce pollution, and enhance anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

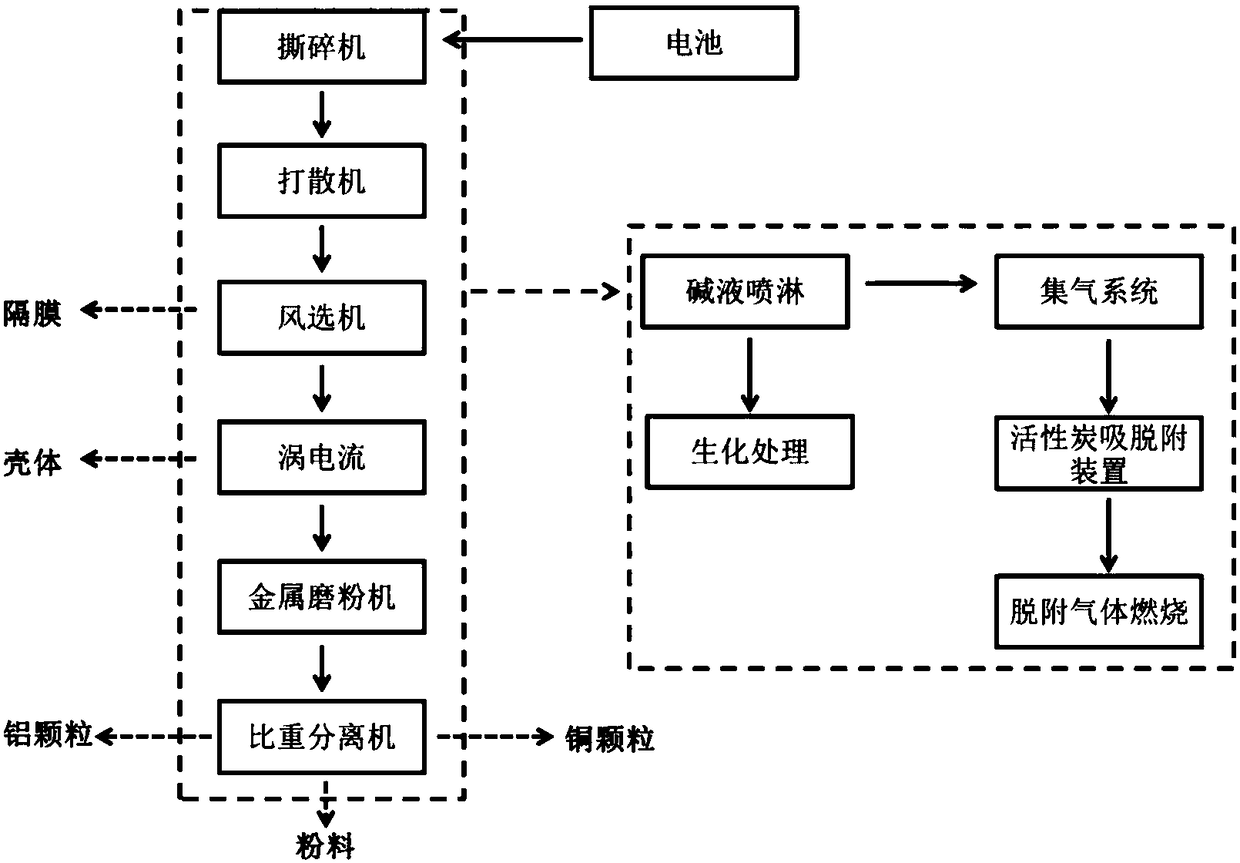

[0027] A safe treatment method for charged lithium-ion batteries, including six processes of rapid crushing, rapid dispersal, negative pressure sorting plastic diaphragms, eddy current sorting shells, grinding, and specific gravity separation, so as to separate the shells of charged lithium-ion batteries Body fragments, plastic diaphragm fragments, copper particles, aluminum particles and battery powder are separated individually, and the waste gas generated in the process is collected and treated in a centralized manner, and zero discharge of waste water is realized.

[0028] Among them, the single crushing process of a charged lithium-ion battery shall not exceed 0.5s, and it shall fall directly into the dispersing machine after breaking up. The breaking time shall not exceed 0.5s, and the total breaking and breaking process shall not exceed 1s. Negative pressure separation requires air humidity to be kept below 20%. To reduce the generation of hydrofluoric acid and slow dow...

Embodiment 2

[0030] A safe treatment method for charged lithium-ion batteries, including six processes of rapid crushing, rapid dispersal, negative pressure sorting plastic diaphragms, eddy current sorting shells, grinding, and specific gravity separation, so as to separate the shells of charged lithium-ion batteries Body fragments, plastic diaphragm fragments, copper particles, aluminum particles and battery powder are separated individually, and the waste gas generated in the process is collected and treated in a centralized manner, and zero discharge of waste water is realized.

[0031] Among them, the single crushing process of a charged lithium-ion battery shall not exceed 0.5s, and it shall fall directly into the dispersing machine after breaking up. The breaking time shall not exceed 0.5s, and the total breaking and breaking process shall not exceed 1s. Negative pressure separation requires air humidity to be kept below 20%. To reduce the generation of hydrofluoric acid and slow dow...

Embodiment 3

[0034] A safe treatment method for charged lithium-ion batteries, including six processes of rapid crushing, rapid dispersal, negative pressure sorting plastic diaphragms, eddy current sorting shells, grinding, and specific gravity separation, so as to separate the shells of charged lithium-ion batteries Body fragments, plastic diaphragm fragments, copper particles, aluminum particles and battery powder are separated individually, and the waste gas generated in the process is collected and treated in a centralized manner, and zero discharge of waste water is realized.

[0035] Among them, the single crushing process of a charged lithium-ion battery shall not exceed 0.5s, and it shall fall directly into the dispersing machine after breaking up. The breaking time shall not exceed 0.5s, and the total breaking and breaking process shall not exceed 1s. Negative pressure separation requires air humidity to be kept below 20%. To reduce the generation of hydrofluoric acid and slow dow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap