Method for preparing steelmaking dust briquettes

A manufacturing method and dust technology, applied in the direction of improving process efficiency, etc., can solve problems such as briquette structure cracking, and achieve the effect of reducing the decline rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

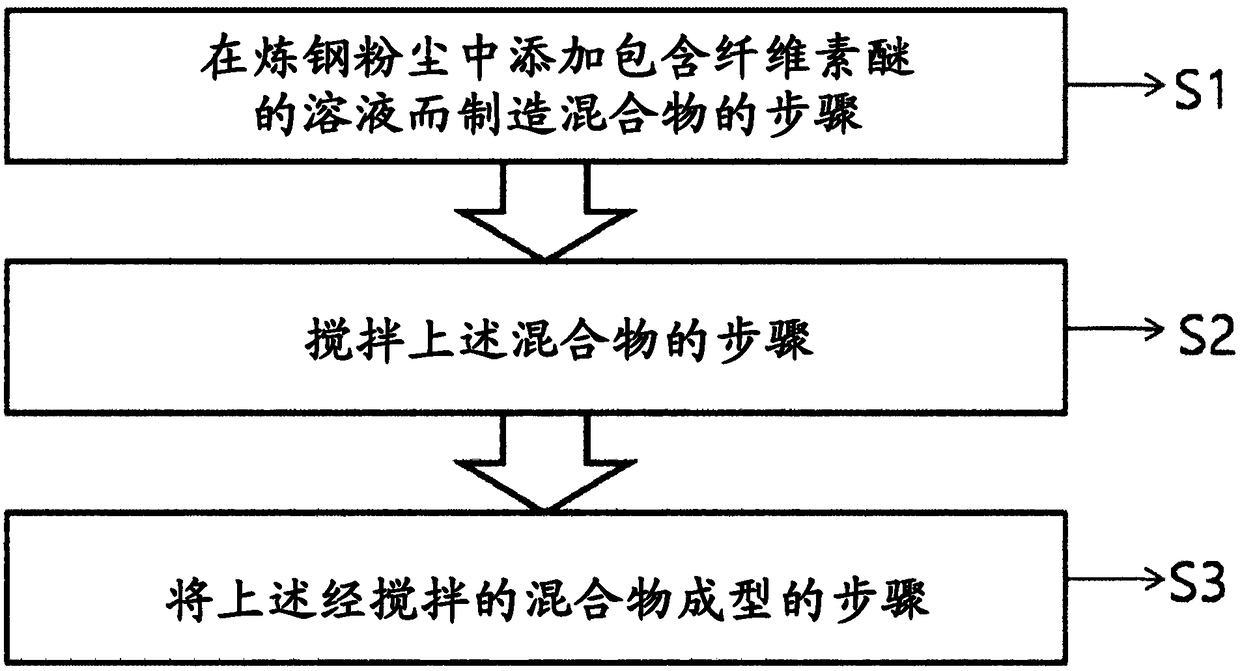

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~6

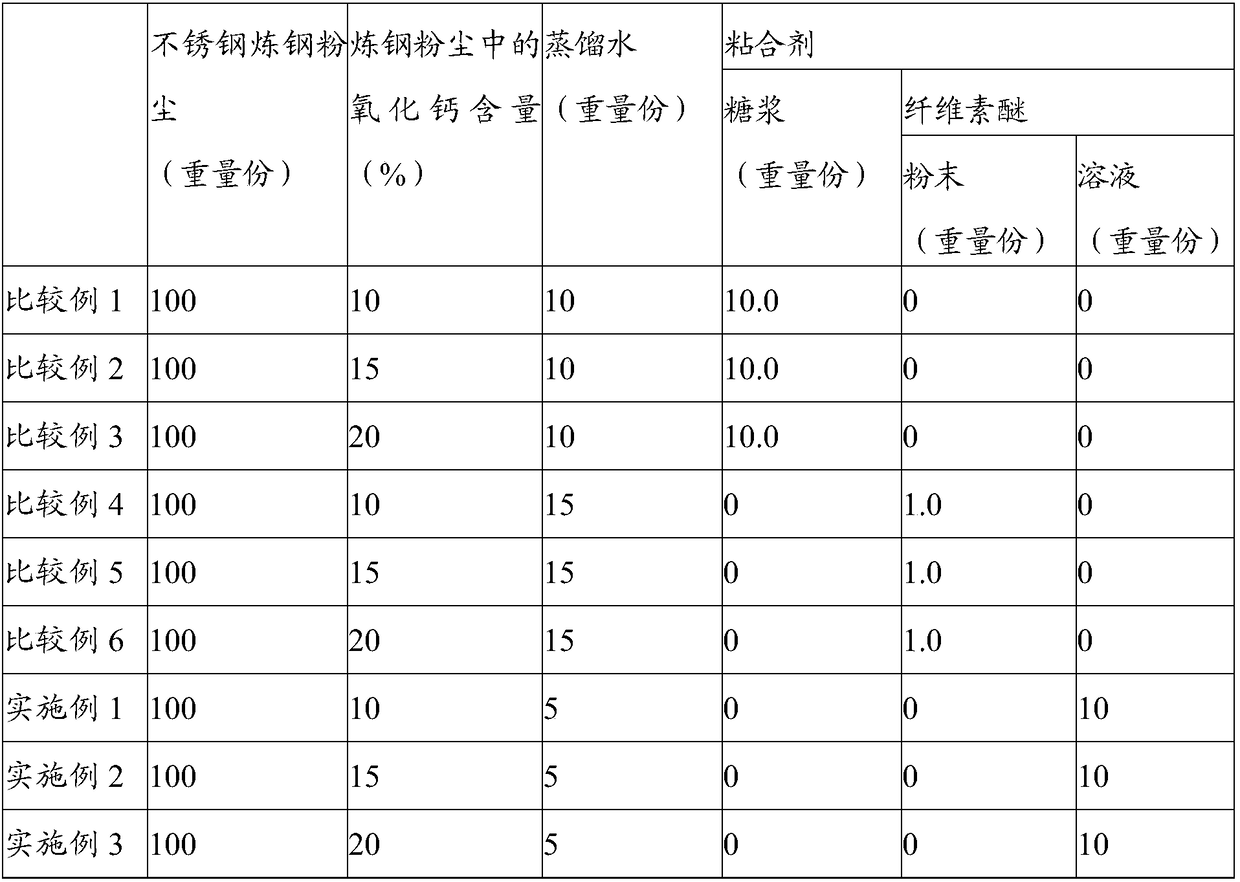

[0033] A mixture having a compounding ratio shown in Table 1 below was prepared. In Table 1 below, stainless steelmaking dust was used by purchasing stainless steelmaking dust whose calcium oxide content was known from a Korean steel company.

[0034] [Table 1]

[0035]

[0036] Syrup: SYSTRONICS, Syrup

[0037] Cellulose ether: Samsung Fine Chemicals,

[0038] Cellulose ether solution: 10% by weight cellulose ether solution, Samsung Fine Chemicals,

[0039] Each mixture having the composition of Table 1 above was stirred for 5 minutes using a stirrer (Erich). Thereafter, each of the above-mentioned stirred mixtures was extrusion-molded using a Briquette machine (HOISTDEST, JCB250T) to produce an oval-shaped briquette having a size of width 45 mm×length 22 mm×thickness 14 mm.

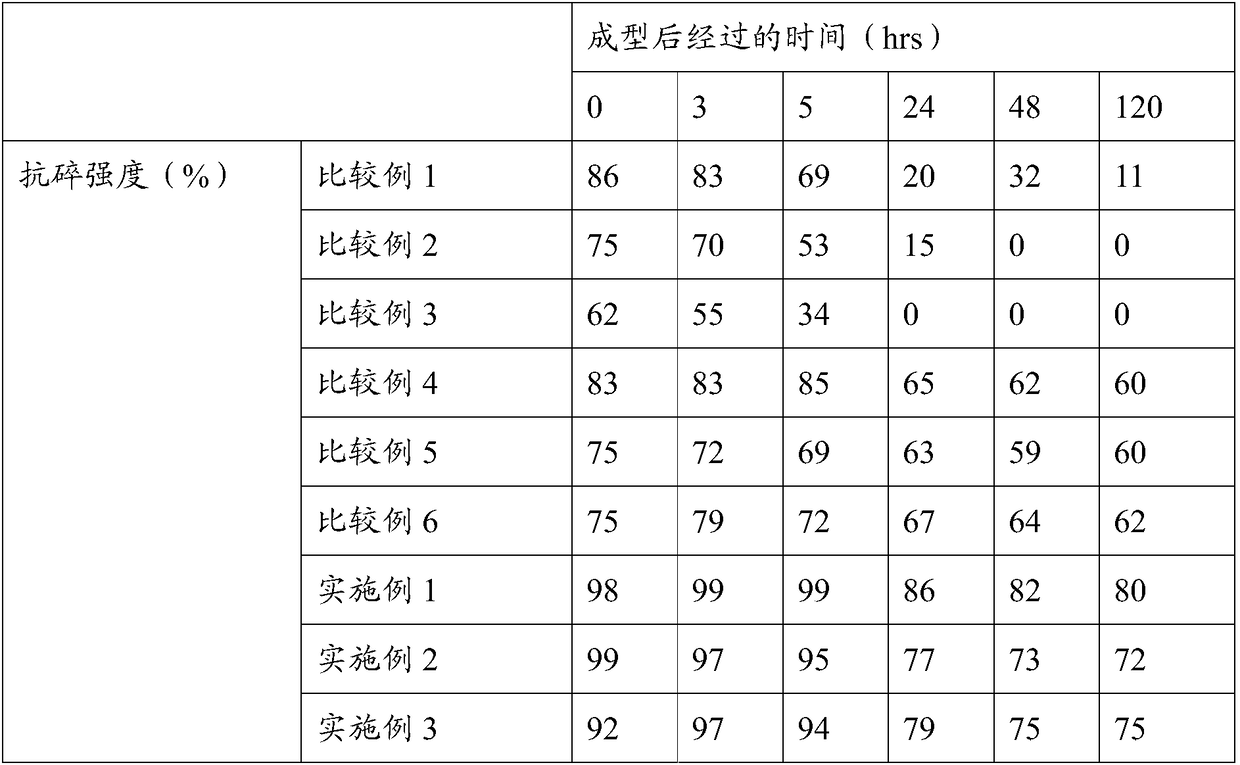

[0040] Evaluation example

[0041] (Evaluation of crushing strength)

[0042] 20 briquettes manufactured from mixtures having the compounding ratios of Examples 1 to 3 and Comparative Examp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap