Method for preparing composite magnetic catalyst of magnetic solid sulfonic acid loaded amine catalyst and application thereof

A composite magnetism and catalyst technology, which is applied in the preparation of organic compounds, catalytic reactions, and preparation of carboxylic acid nitriles, etc., to achieve the effects of high product yield, improved activity, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation and application of embodiment 1, composite catalyst MSA / A1

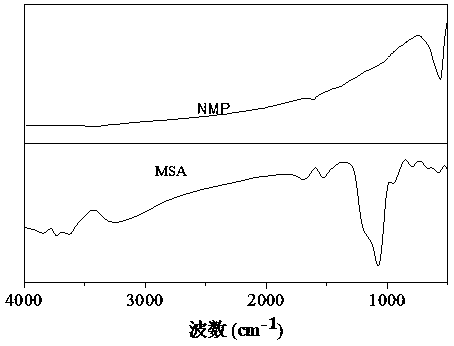

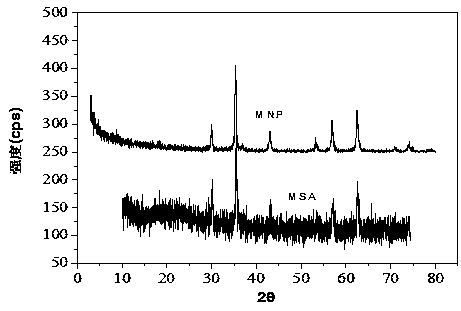

[0034] Fe 3 o 4 Preparation of magnetic particles: Take 2.6 g FeCl 3 •6H 2 O was dissolved in 50 mL of ethylene glycol solution with vigorous stirring to form a clear solution, and then 5.75 g of NaAc and 1.0 g of polyethylene glycol were added. The mixture was magnetically stirred for 30 min to obtain a dark brown-yellow viscous liquid. Afterwards, the liquid was transferred into a 50 mL polytetrafluoroethylene-lined stainless steel reaction kettle, and the temperature was raised to 200 °C in a constant temperature blast drying oven. After 8 h of reaction, it was naturally cooled to room temperature. After taking out the solution in the kettle, wash it several times with absolute ethanol and deionized water, and dry it under vacuum at 60° C. to obtain a black powder. References (Li Y D, Deng H, Li XL, Peng Q, Wang X, Chen J P. Angew. Chem. Int. Ed , 2005, 44 , 2782- 2785.) Preparation of F...

Embodiment 2

[0047] The preparation and application of embodiment 2, composite catalyst MSA / A2

[0048] Fe 3 o 4 Preparation of magnetic particles: same as Example 1;

[0049] Mercapto-coated spherical Fe3O4 3 o 4 @SiO 2 -The preparation of SH: with embodiment 1

[0050] The preparation of magnetic sulfonic acid MSA: with embodiment 1;

[0051] Preparation of composite catalyst MSA / A2: magnetic sulfonic acid MSA (1.0 g, 0.5 mmol) was suspended in CH 2 Cl 2 (20 mL), and the reaction mixture was stirred at room temperature for 15 minutes. then add N 1 ,N 1 ,N 2 ,N 2 - Tetramethylethane-1,2-diamine (A2) (70 mg, 0.6 mmol), and the resulting mixture was stirred at room temperature for 0.5 hours. Use an external magnet to attract and separate the catalyst, and use CH 2 Cl 2 washing. The resulting solid was dried under vacuum overnight at room temperature to afford MSA / A2 in 97% yield. Its reaction formula is as follows:

[0052]

[0053] Knoevenagel condensation reaction: p-...

Embodiment 3

[0054] The preparation of embodiment 3, composite catalyst MSA / A3

[0055] Fe 3 o 4 Preparation of magnetic particles: same as Example 1;

[0056] Mercapto-coated spherical Fe3O4 3 o 4 @SiO 2 -The preparation of SH: with embodiment 1

[0057] The preparation of magnetic sulfonic acid MSA: with embodiment 1;

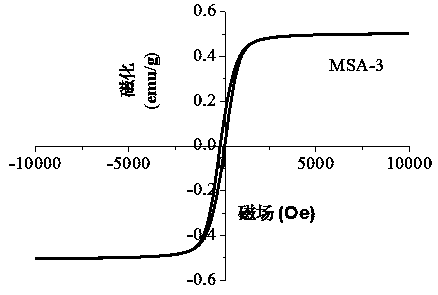

[0058] Preparation of composite catalyst MSA / A3: magnetic sulfonic acid MSA (1.0 g, 0.5 mmol) was suspended in CH 2 Cl 2 (20 mL), and the reaction mixture was stirred at room temperature for 15 minutes. 4-Dimethylaminopyridine (A3) was then added. (73 mg, 0.6 mmol), and the resulting mixture was stirred at room temperature for 0.5 hours. Use an external magnet to attract and separate the catalyst, and use CH 2 Cl 2 washing. The resulting solid was dried under vacuum overnight at room temperature to afford MSA / A3 in 98% yield. Its reaction formula is as follows:

[0059]

[0060] Knoevenagel condensation reaction: p-chlorobenzaldehyde (0.5mmol), ethyl cya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com