Low-dust low-nitrogen electric welding rod and preparation method thereof

A technology of welding rods and welding cores, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of welding personnel hazards, easy diffusion of dust, complicated welding positions, etc., and achieve the effect of improving mechanical properties and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

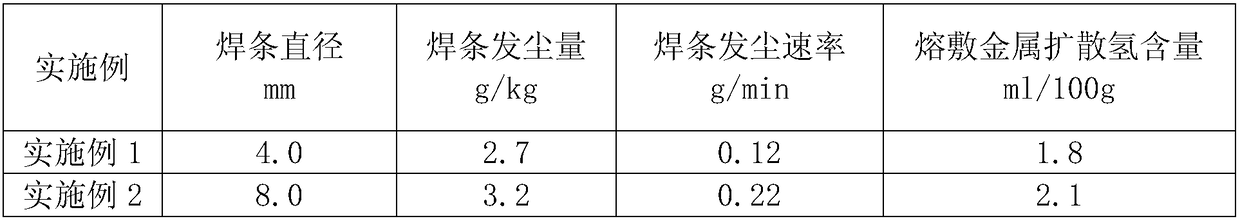

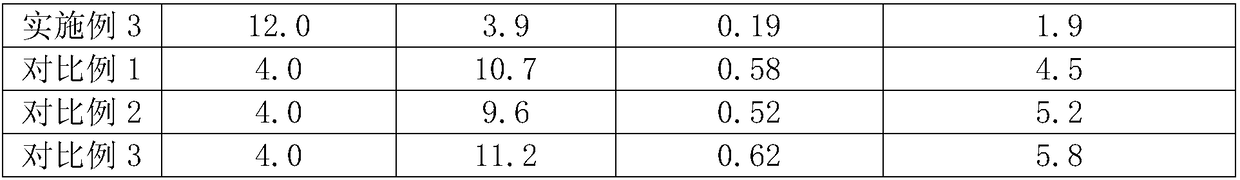

Embodiment 1

[0043]The drug skin is made of the following raw materials in mass percentage: titanium dioxide: 11.5%, wollastonite: 25.5%, barium carbonate: 11%, magnesite: 9%, talcum powder: 10%, silicon aluminum barium: 5% %, manganese metal: 4.5%, low-carbon ferromanganese: 5%, ferro-titanium: 5%, aluminum powder: 4%, starch: 3%, rice husk powder: 5%, and binder: 1.5%; The welding core is H08C welding steel; the coating weight coefficient is 10%.

[0044] Preparation method: mix the powder of the above raw materials evenly, add a mixture of alginic acid and glutinous rice water with a mass ratio of 2:1 and a total mass of 1.5% of the total mass of the drug skin, and press evenly on H08C welding after stirring On the surface of the steel welding core, make a semi-finished electrode with a diameter of 4.0mm and a length of 250mm, then dry the semi-finished electrode at room temperature and then dry it at 180°C for 2 hours, and then make a low-dust and low-hydrogen electrode .

Embodiment 2

[0046] The drug skin is made of the following raw materials in mass percentage: titanium dioxide: 10%, wollastonite: 26%, barium carbonate: 14.4%, magnesite: 8%, talcum powder: 14.4%, silicon aluminum barium: 8% %, manganese metal: 5%, low-carbon ferromanganese: 2%, ferro-titanium: 3%, aluminum powder: 2%, starch: 2%, rice husk powder: 4%, and binder: 1.2%; The welding core is H08C welding steel; the coating weight factor is 12%.

[0047] Preparation method: Mix the powder of the above raw materials evenly, then add the mixture of alginic acid and glutinous rice water with a mass ratio of 2:1 and a total mass of 1.2% of the total mass of the drug skin, and press evenly on H08C welding after stirring On the surface of the steel welding core, make a semi-finished electrode with a diameter of 8.0mm and a length of 300mm, then dry the semi-finished electrode at room temperature and then dry it at 185°C for 2 hours, and then make a low-dust and low-hydrogen electrode. .

Embodiment 3

[0049] The drug skin is made of the following raw materials in mass percentage: titanium dioxide: 11%, wollastonite: 25.6%, barium carbonate: 12.5%, magnesite: 9%, talcum powder: 11%, silicon aluminum barium: 6% %, manganese metal: 3%, low-carbon ferromanganese: 3%, ferro-titanium: 4%, aluminum powder: 2.5%, starch: 4%, rice husk powder: 7%, and binder: 1.4%; welding core H08C welding steel is used; the coating weight factor is 11%.

[0050] Preparation method: Mix the powder of the above raw materials evenly, then add the mixture of alginic acid and glutinous rice water with a mass ratio of 2:1 and a total mass of 1.4% of the total mass of the drug skin, and press evenly on H08C welding after stirring On the surface of the steel welding core, a semi-finished electrode with a diameter of 12mm and a length of 350mm is made, and then the semi-finished electrode is dried at room temperature and then dried at 190°C for 2 hours. After completion, a low-dust and low-hydrogen electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com