A device and method for improving the purity of acetylene gas while removing mercury from mercury-containing wastewater

A technology of acetylene gas and acetylene gas tank, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, water pollutants, etc., to achieve the effects of reducing sodium hypochlorite consumption, low energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

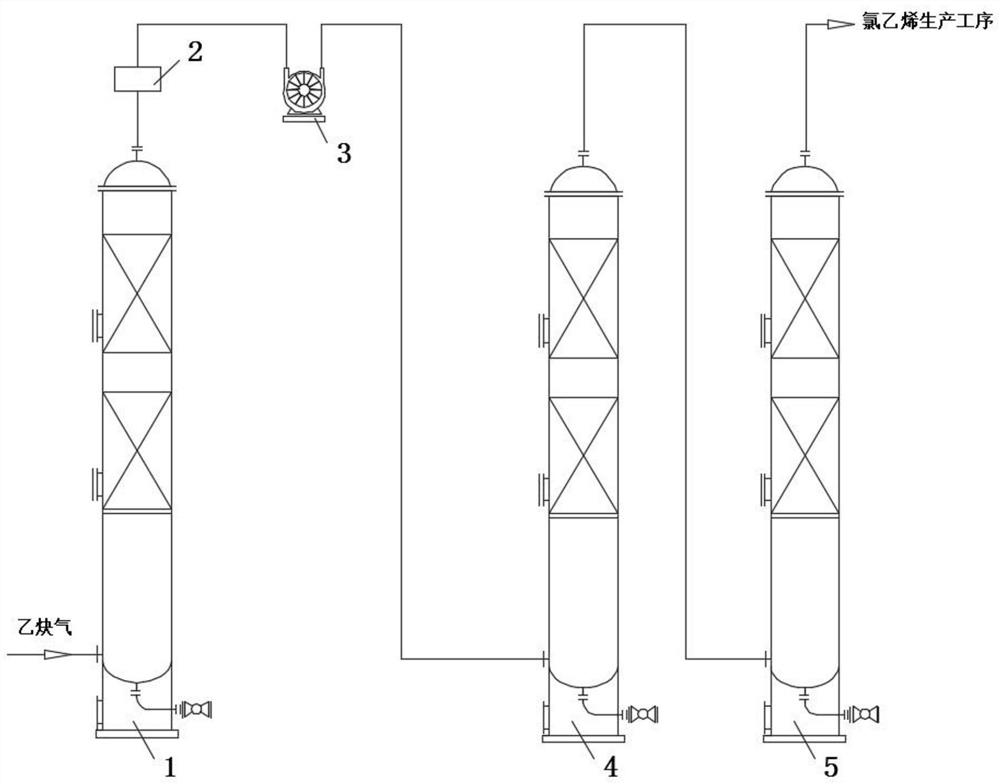

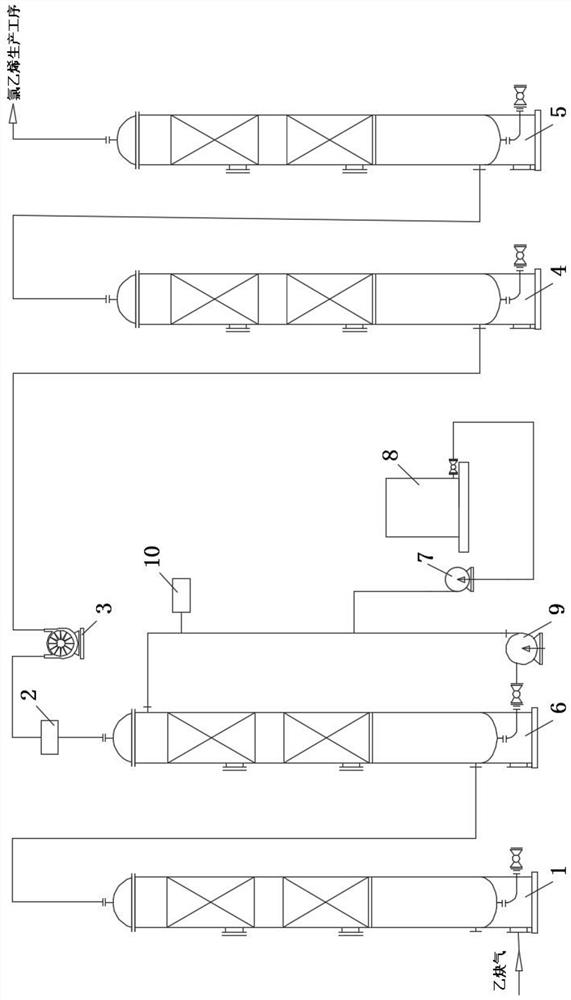

[0035] The device for improving the purity of acetylene gas while removing mercury from mercury-containing wastewater of this embodiment includes a cooling tower 1, an acetylene gas cabinet 2, a booster 3, a clean first tower 4, and a clean second tower 5, the acetylene gas cabinet 2 The gas outlet is sequentially connected to the booster 3, the first clean tower 4 and the second clean tower 5, and also includes a mercury-containing waste water scrubber 6;

[0036] The mercury-containing wastewater washing tower 6 includes a tower body, the bottom side wall of the tower body is provided with an air inlet, and is connected with the air outlet of the cooling tower 1;

[0037] The top of the tower body is provided with an air outlet, and is connected with the air inlet of the acetylene gas cabinet 2;

[0038] The upper side wall of the tower body is provided with a liquid inlet, and is connected with the mercury-containing waste water collection tank 8 through the first lift pump...

Embodiment 2

[0049] The device for improving the purity of acetylene gas while removing mercury from mercury-containing wastewater in this embodiment is the same as that in Embodiment 1.

[0050] A method for improving the purity of acetylene gas while using the above-mentioned device to remove mercury from mercury-containing wastewater comprises the following steps:

[0051] Step 1: the crude acetylene gas enters the cooling tower 1 for cooling, the volume percentage of hydrogen sulfide gas in the crude acetylene gas is 0.065%, and the cooled crude acetylene gas enters the mercury-containing waste water washing tower 6;

[0052] Step 2: The mercury-containing wastewater from the mercury-containing wastewater collection tank 8 is lifted by the first lift pump 7 into the liquid inlet of the mercury-containing wastewater washing tower 6, and the mercury content in the mercury-containing wastewater is 29 μg / mL;

[0053] Step 3: Mercury-containing wastewater flows down from the upper part of the...

Embodiment 3

[0058] The device for improving the purity of acetylene gas while removing mercury from mercury-containing wastewater in this embodiment is the same as that in Embodiment 1.

[0059] A method for improving the purity of acetylene gas while using the above-mentioned device to remove mercury from mercury-containing wastewater comprises the following steps:

[0060] Step 1: the crude acetylene gas enters the cooling tower 1 for cooling, the volume percentage of hydrogen sulfide gas in the crude acetylene gas is 0.070%, and the cooled crude acetylene gas enters the mercury-containing waste water washing tower 6;

[0061] Step 2: The mercury-containing wastewater from the mercury-containing wastewater collection tank 8 is lifted by the first lift pump 7 into the liquid inlet of the mercury-containing wastewater washing tower 6, and the mercury content in the mercury-containing wastewater is 32 μg / mL;

[0062] Step 3: Mercury-containing wastewater flows down from the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com