High-performance concrete prepared by adopting rice hull ash, silicon ash and graphene oxide as admixtures and preparation method thereof

A high-performance concrete and admixture technology, applied in the field of building materials, can solve the problems of few or few super-high-strength high-performance concrete, and achieve the effects of improving mechanical properties, improving efficiency, and improving microscopic cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

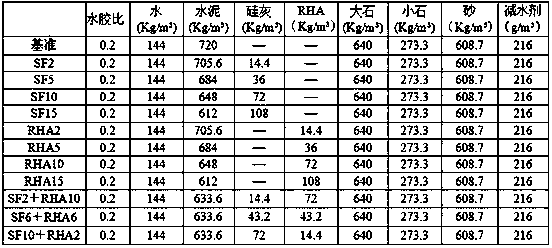

[0024] 1. The preparation process of high-performance concrete prepared by using rice husk ash, silica fume and graphene oxide as admixtures:

[0025] (1) The preparation process of the composite admixture: After the rice husk was incinerated at low temperature for 1 h, it was ground for 1 h with a ball mill to obtain nano-SiO 2 Rice husk ash with a content of more than 90% is mixed with silica fume and graphene oxide to obtain a composite admixture.

[0026] (2) Then mix cement, admixtures, coarse aggregate, fine aggregate, water reducing agent and water according to specific proportions to prepare high-strength and high-performance concrete.

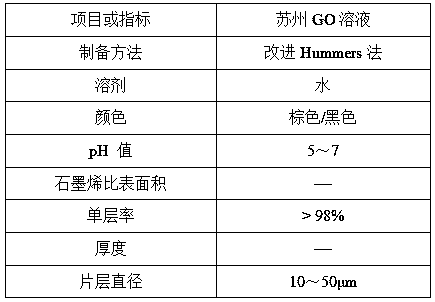

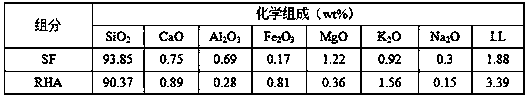

[0027] The graphene oxide (GO) used was the graphene oxide aqueous solution of Suzhou Carbonfeng Technology Co., Ltd. (Suzhou Carbon), see Table 1 for details; the silica fume used was purchased from Elkem International Trade (Shanghai) Co., Ltd., model 920U, cement Purchased from Guangzhou Zhujiang Cement Co., Ltd., it is Jinyang bra...

Embodiment 2

[0046] On the basis of the test results obtained in Example 1, it can be seen that when the compounding ratio of silica fume and rice husk ash is 10%SF+2%RHA, the effect of synergistically improving the performance of cement-based materials is the best, so 10%SF+2%RHA is used %RHA compounded instead of cement as the benchmark group, under a fixed water-cement ratio, explored the effect of different content of graphene oxide (0%, 0.001%, 0.005%, 0.01%) on the working performance and mechanical properties of ultra-high-strength high-performance concrete influences.

[0047] Concrete was prepared according to the formula in Table 5, and the performance test results of the concrete are shown in Table 6.

[0048] Table 5 Formulas for preparing high performance concrete with rice husk ash, silica fume and graphene oxide as composite admixtures

[0049]

[0050] Note: The amount of water needs to deduct the water contained in the GO aqueous solution

[0051] Table 6 Performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com