Ablation-resistant material preparation method

An ablation-resistant, prefabricated technology, applied in the field of engineering materials, can solve problems such as low bonding strength, and achieve the effects of low cost, controllable process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

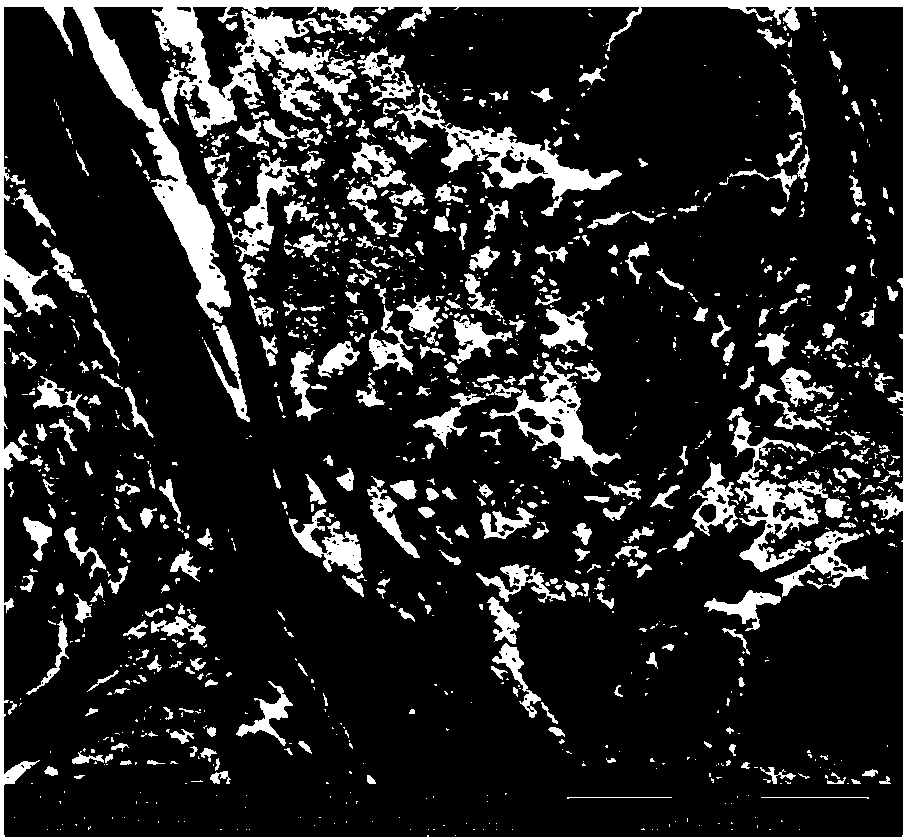

Image

Examples

Embodiment 1

[0020] Carbon fiber needle felt prefabricated body is used. Using propylene as the carbon source gas, a chemical vapor deposition process is used to deposit a pyrolytic carbon layer on the surface of the carbon fiber of the preform. The specific conditions are as follows: the deposition temperature is 1020-1030°C, the pressure is 3-5KPa, the propylene flow rate is 4-6L / min, the deposition time is 40-50h, and the density of the sample after deposition is 0.8g / cm 3 . Put the carbon fiber prefabricated body deposited with the carbon interface layer into the vacuum impregnation device, slowly add the HfC ceramic phase precursor impregnation solution, control the vacuum degree below 0.5KPa, and the impregnation time is between 60-90min. Transfer the impregnated sample to an oven, adjust the oven temperature to 180-200°C, dry for 8-10 hours, and put the cross-linked and cured sample into a heat treatment furnace, and adjust the heating rate to 5-10 hours. 8°C / min, the temperature ...

Embodiment 2

[0022] Carbon fiber needle felt prefabricated body is used. Using propylene as the carbon source gas, a chemical vapor deposition process is used to deposit a pyrolytic carbon layer on the surface of the carbon fiber of the preform. The specific conditions are as follows: the deposition temperature is 1020-1030°C, the pressure is 3-5KPa, the propylene flow rate is 4-6L / min, the deposition time is 80-90h, and the density of the sample after deposition is 1.0g / cm 3 . Put the carbon fiber prefabricated body deposited with the carbon interface layer into the vacuum impregnation device, slowly add the HfC ceramic phase precursor impregnation solution, control the vacuum degree below 0.5KPa, and the impregnation time is between 60-90min. Transfer the impregnated sample to an oven, adjust the oven temperature to 180-200°C, dry for 8-10 hours, and put the cross-linked and cured sample into a heat treatment furnace, and adjust the heating rate to 5-10 hours. 8°C / min, the temperature ...

Embodiment 3

[0024] Carbon fiber needle felt prefabricated body is used. Using propylene as the carbon source gas, a chemical vapor deposition process is used to deposit a pyrolytic carbon layer on the surface of the carbon fiber of the preform. The specific conditions are as follows: the deposition temperature is 1020-1030°C, the pressure is 3-5KPa, the propylene flow rate is 4-6L / min, the deposition time is 130-140h, and the density of the sample after deposition is 1.2g / cm 3 . Put the carbon fiber prefabricated body deposited with the carbon interface layer into the vacuum impregnation device, slowly add the HfC ceramic phase precursor impregnation solution, control the vacuum degree below 0.5KPa, and the impregnation time is between 60-90min. Transfer the impregnated sample to an oven, adjust the oven temperature to 180-200°C, dry for 8-10 hours, and put the cross-linked and cured sample into a heat treatment furnace, and adjust the heating rate to 5-10 hours. 8°C / min, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com