Preparation method of mildew-proof waterproof paint

A waterproof coating and anti-mildew technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as failure, high water solubility, and anti-fungal agents flowing into water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

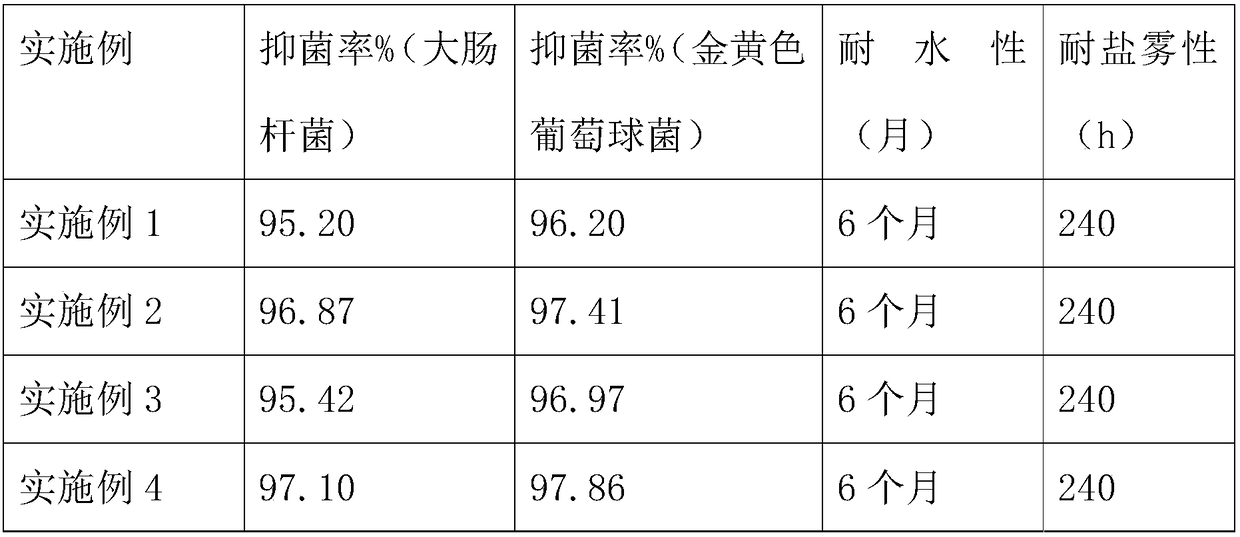

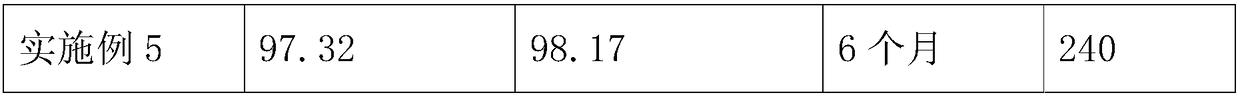

Examples

Embodiment 1

[0021] S1: Mix 20 parts of butyl acrylate, 15 parts of vinyl triethoxy silane, 10 parts of tert-amyl alcohol and 8 parts of carboxyl styrene butadiene latex, stir and mix at 1000 rpm for 40 minutes to obtain mixed solution A, which is kept for later use;

[0022] S2: Mix 20 parts of tetraethyl silicate, 4 parts of nano silver, 3 parts of nano copper, 3 parts of nano zinc oxide, and 10 parts of citric acid, stir and mix at 1000 rpm for 30 minutes to obtain mixed solution B, and place it for use;

[0023] S3: Mix the mixed solution A in step S1 with the mixed solution B in step S2, adjust the pH to between 7.8, and raise the temperature to 80°C, add 10 parts of nonylphenol polyoxyethylene ether and 4 parts of 1,2-benzoiso Thiazole, stirring at 1500rpm for 25min;

[0024] S4: Add 5 parts of polyacrylamide and 4 parts of hydroxyethyl methyl cellulose to step S3, adjust the temperature to 60°C, stir at 1000 rpm for 30 minutes, and obtain the mildew-proof and waterproof coating after cooli...

Embodiment 2

[0026] S1: Mix 30 parts of butyl acrylate, 25 parts of vinyl triethoxy silane, 20 parts of tert-amyl alcohol and 15 parts of carboxyl styrene-butadiene latex, stir and mix at 2000 rpm for 60 minutes to obtain mixed solution A, which is kept for later use;

[0027] S2: Mix 30 parts of tetraethyl silicate, 6 parts of nano silver, 7 parts of nano copper, 8 parts of nano zinc oxide and 15 parts of citric acid, stir and mix at 2000 rpm for 70 minutes to obtain mixed solution B, and place it for use;

[0028] S3: Mix the mixed solution A in step S1 with the mixed solution B in step S2, adjust the pH to 8.8, raise the temperature to 100°C, add 20 parts of nonylphenol polyoxyethylene ether and 9 parts of 1,2-benzoiso Thiazole, stirring at 2500rpm for 35min;

[0029] S4: Add 10 parts of polyacrylamide and 8 parts of hydroxyethyl methyl cellulose to step S3, adjust the temperature to 80°C, stir at 2000 rpm for 50 minutes, and obtain the mildew-proof and waterproof coating after cooling.

Embodiment 3

[0031] S1: Mix 22 parts of butyl acrylate, 17 parts of vinyl triethoxy silane, 12 parts of tert-amyl alcohol and 10 parts of carboxyl styrene butadiene latex, stir and mix at 1400 rpm for 45 minutes to obtain mixed solution A, which is placed for later use;

[0032] S2: Mix 25 parts of tetraethyl silicate, 4 parts of nano silver, 4 parts of nano copper, 5 parts of nano zinc oxide and 12 parts of citric acid, stir and mix at 1700 rpm for 40 minutes to obtain mixed solution B, and place it for use;

[0033] S3: Mix the mixed solution A in step S1 with the mixed solution B in step S2, adjust the pH to between 8.2, heat up to 85°C, add 15 parts of nonylphenol polyoxyethylene ether and 5 parts of 1,2-benzoiso Thiazole, stirring at 1800rpm for 28min;

[0034] S4: Add 7 parts of polyacrylamide and 6 parts of hydroxyethyl methylcellulose to step S3, adjust the temperature to 65°C, stir at 1500 rpm for 35 minutes, and obtain the mildew-proof and waterproof coating after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com