Negative-ion coating for power distribution cabinet and preparation method thereof

A technology for negative ion coatings and power distribution cabinets, which is applied in coatings and other directions, can solve the problems of insignificant release effects, toxic and harmful components, and poor promotion effects, so as to increase the release of negative ions, reduce the content of volatile organic compounds, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

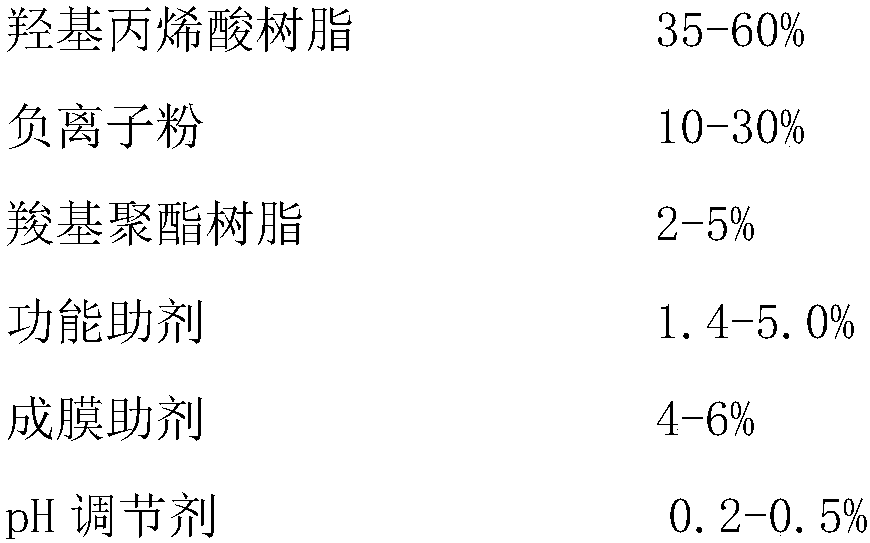

[0029] This implements a kind of negative ion paint for power distribution cabinet, and the raw material composition that comprises following mass percentage is shown in Table 1:

[0030] The power distribution cabinet of table 1 embodiment 1 is used negative ion paint raw material

[0031]

[0032] The specific preparation steps of the negative ion coating for the distribution cabinet of the present embodiment are as follows:

[0033] (1) First, add hydroxyl polyurethane resin and functional additives into the reactor and stir at room temperature for 20 minutes to fully emulsify;

[0034] (2) carboxyl polyester resin and negative ion powder are added in the reactor successively, stirring speed 2000rpm, high-speed dispersion, obtain the emulsion of uniform dispersion;

[0035] (3) Finally, the film-forming aid, pH regulator and water are added to react to adjust the pH and viscosity of the system. After the system is stable, the required negative ion coating for power dist...

Embodiment 2

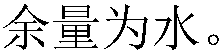

[0037] This implements a kind of negative ion paint for power distribution cabinet, and the raw material composition that comprises following mass percentage is shown in Table 2:

[0038] The power distribution cabinet of table 2 embodiment 2 is used negative ion paint raw material

[0039]

[0040]

[0041] The specific preparation method of the negative ion paint for the distribution cabinet of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0043] This implements a kind of negative ion paint for power distribution cabinet, and the raw material composition that comprises following mass percentage is shown in Table 3:

[0044] The power distribution cabinet of table 3 embodiment 3 is used negative ion paint raw material

[0045]

[0046] The specific preparation method of the negative ion paint for the distribution cabinet of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com