Core-shell quantum dot material highly compatible to packaging silicon rubber and preparation method of core-shell quantum dot material

A core-shell quantum dot and quantum dot technology, which is applied in the field of nano-fluorescent materials, can solve the problems of increased surface defects of materials, uneven and unreliable growth of ligands, and poor control of the proportion of ligands, so as to simplify the preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

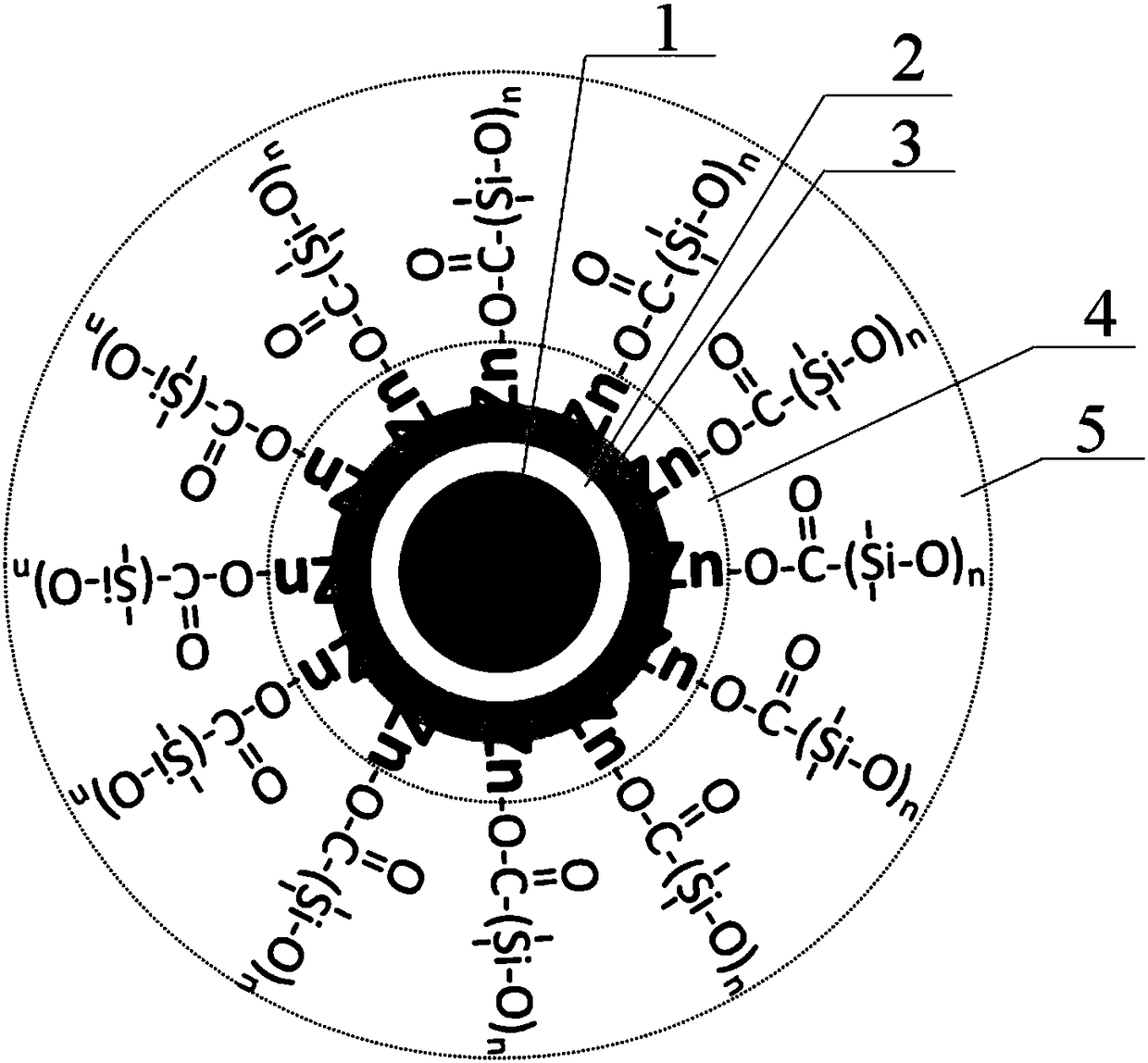

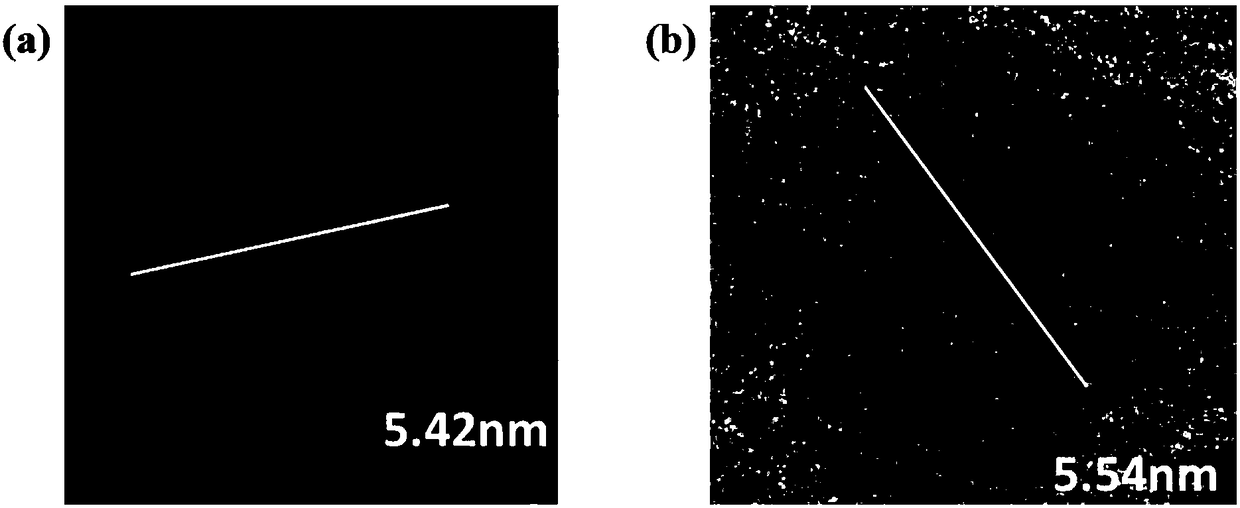

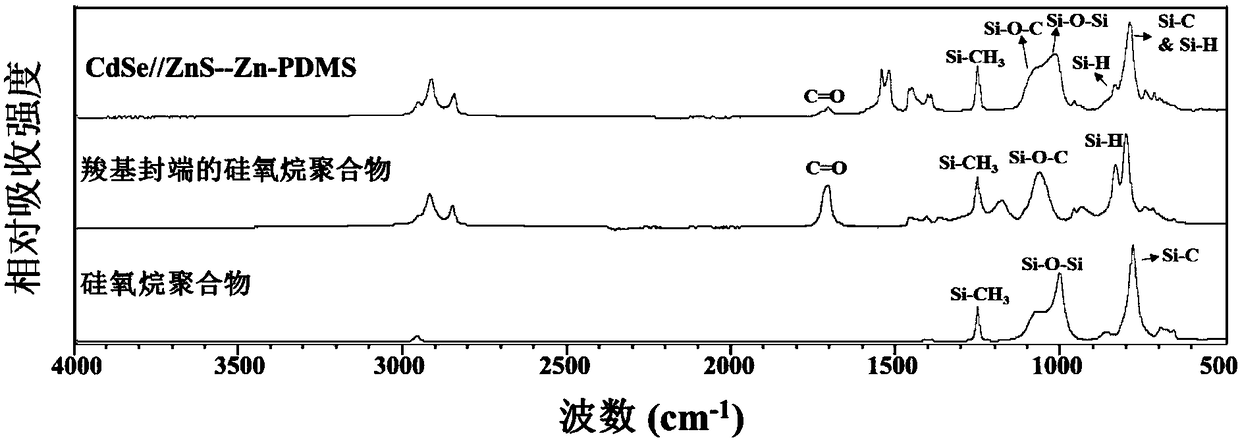

[0036] Example 1: CdSe / / CdS / ZnS--Zn-PDMS (CdSe / / CdS / ZnS core-shell structure quantum dots containing Zn-PDMS functional ligand structure) silica gel highly compatible quantum dot material

[0037] The first step is the preparation of Zn-PDMS (zinc-terminated organosiloxane polymer) functional ligand

[0038] In the glove box (the water and oxygen content does not exceed 0.1ppm), under stirring, drip 1M (mmol / mL) dimethyl zinc toluene solution (solution A) into 0.5M carboxyl-terminated polydimethylsiloxane In alkane (viscosity cSt15-30, referred to as DMS-B12) octadecene solution (solution B), until there are no bubbles in the mixed solution, the volume ratio of the mixed solution is A:B=1:5, and stir at room temperature for 2 hours, and the stirring speed is 350 revolutions per minute to obtain Zn-PDMS ligand solution C;

[0039] The second step is to prepare a CdSe / / CdS / ZnS core-shell structure quantum dot solution

[0040] Under ordinary circumstances, dissolve CdSe / / CdS / ZnS core-s...

Embodiment 2

[0049] Example 2: CdSe / / ZnS--Al-PDMS structure silica gel highly compatible quantum dot material

[0050] The first step is the preparation of Al-PDMS (aluminum terminated organosiloxane polymer) functional ligand

[0051] In the glove box (the water and oxygen content does not exceed 0.1ppm), under stirring, drip 1M (mmol / mL) trimethylaluminum n-hexane solution (solution A) into the 1M carboxyl-terminated polysiloxane 18 In the olefin solution (solution B), until there are no bubbles in the mixed solution, the volume ratio of the mixed solution is A:B≈1:10, and the mixture is stirred at room temperature for 2 hours, and the stirring speed is 350 revolutions per minute to obtain Al-PDMS ligand solution C;

[0052] Except that in the second step, the solution solute is prepared as CdSe / / ZnS core-shell quantum dots, and the other steps are the same as in Example 1.

[0053] The material of the present invention obtained in Example 2 has a structure such as Figure 8 Shown is a "core / / s...

Embodiment 3

[0054] Example 3: CuInSe / / ZnS---Zn-PDMS structure silica gel highly compatible quantum dot material

[0055] Except for the second step, the solute of the prepared solution is CuInSe / / ZnS core-shell quantum dots, and the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com