A kind of Sclerotinum and method for fermenting and producing scleroglucan

A technology of Sclerotinia and dextran, applied in the field of microorganisms, can solve problems such as high production costs, waste of resources, and troublesome follow-up processing of products, and achieve the effect of increasing substrate utilization and reducing costs significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The isolation and identification of embodiment 1 bacterial strain

[0024] The strains isolated earlier were inoculated on PDA medium, the genomic DNA of the strains was extracted, and the gene sequence of 18S rDNA was amplified (the universal primers for PCR amplification were NS1F and NS8R). The PCR product was identified by 1% agarose gel electrophoresis, and the result was good. The PCR amplification product was sent to Sangon Bioengineering (Shanghai) Co., Ltd. for sequencing, and the sequencing results were compared with BLAST sequences on the NCBI website, and it was determined to be Sclerotium rolfsii.

[0025] The key substantive difference between the Sclerotinia provided by the present invention and the existing Sclerotinia: Compared with the existing Sclerotinia, the Sclerotinia provided by the present invention is easier to use glucose to produce scleroglucan. In the culture medium of glucose and glucose, the yield in the glucose medium is obviously better...

Embodiment 2

[0026] The cultivation of embodiment 2 Sclerotin and the fermentation of scleroglucan

[0027] Fermentation medium (g / L): KH 2 PO 4 1.0; KCL 0.5; citric acid 1.5; MgSO 4 ·7H 2 O 0.5g / L; pH4.0; add different amounts of glucose (45, 50, 55), NaNO 3 (2, 2.25, 2.5), yeast extract powder (0.2, 0.37, 0.5).

[0028] Shake flask culture: inoculate an appropriate amount of mycelia into a 250ml shake flask containing 50ml of seed medium, culture at 28°C and 220r / min for 72h, and transfer 5% of the inoculum to a 25ml glucose fermentation medium. In a 250ml shake flask, culture at 30°C and 220r / min for 96h.

[0029] Adjust the part components (as shown in Table 1) of fermentation medium respectively, all the other components remain unchanged:

[0030] Table 1 Composition adjustment and corresponding yield of fermentation medium

[0031] serial number Glucose (g / L) NaNO 3 (g / L)

[0032] The results show that the culture medium formula (g / L): glucose 55; NaNO 3 2.2...

Embodiment 3

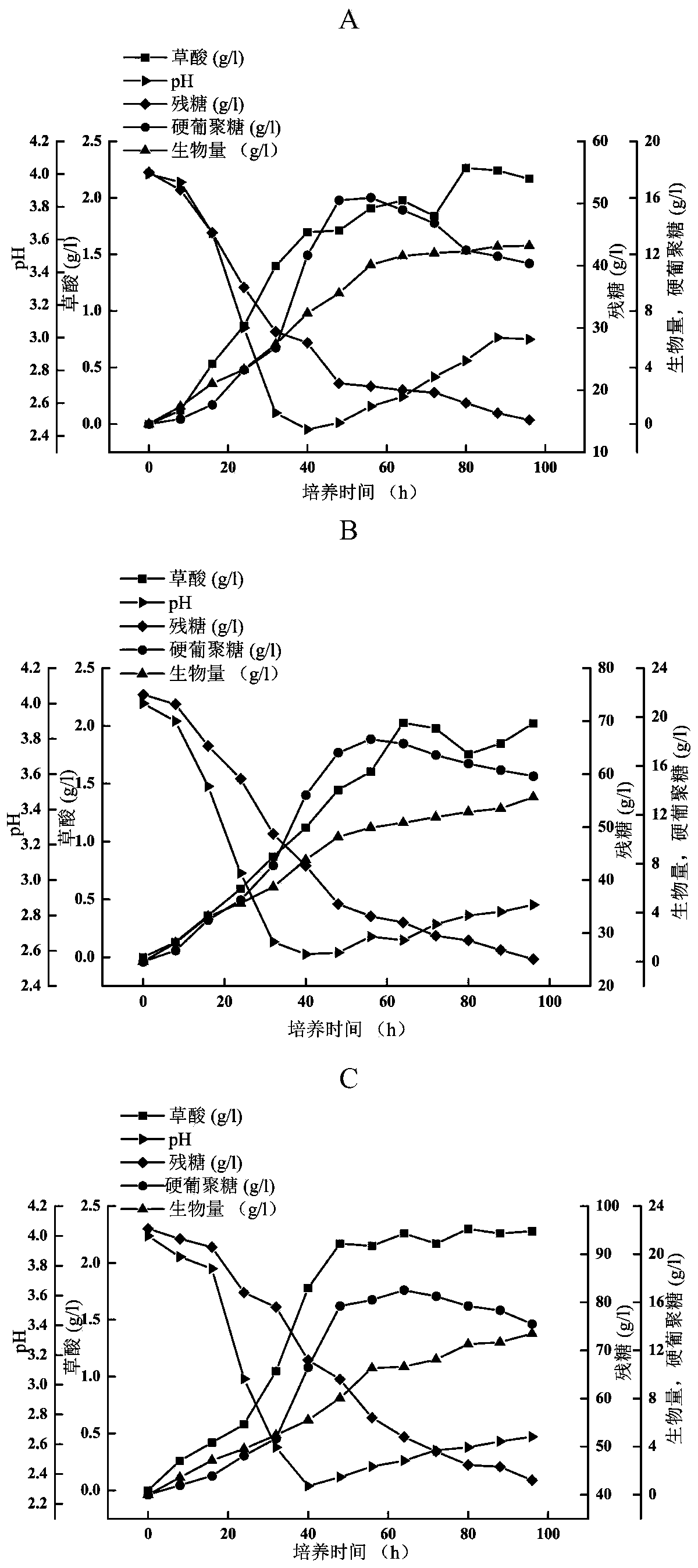

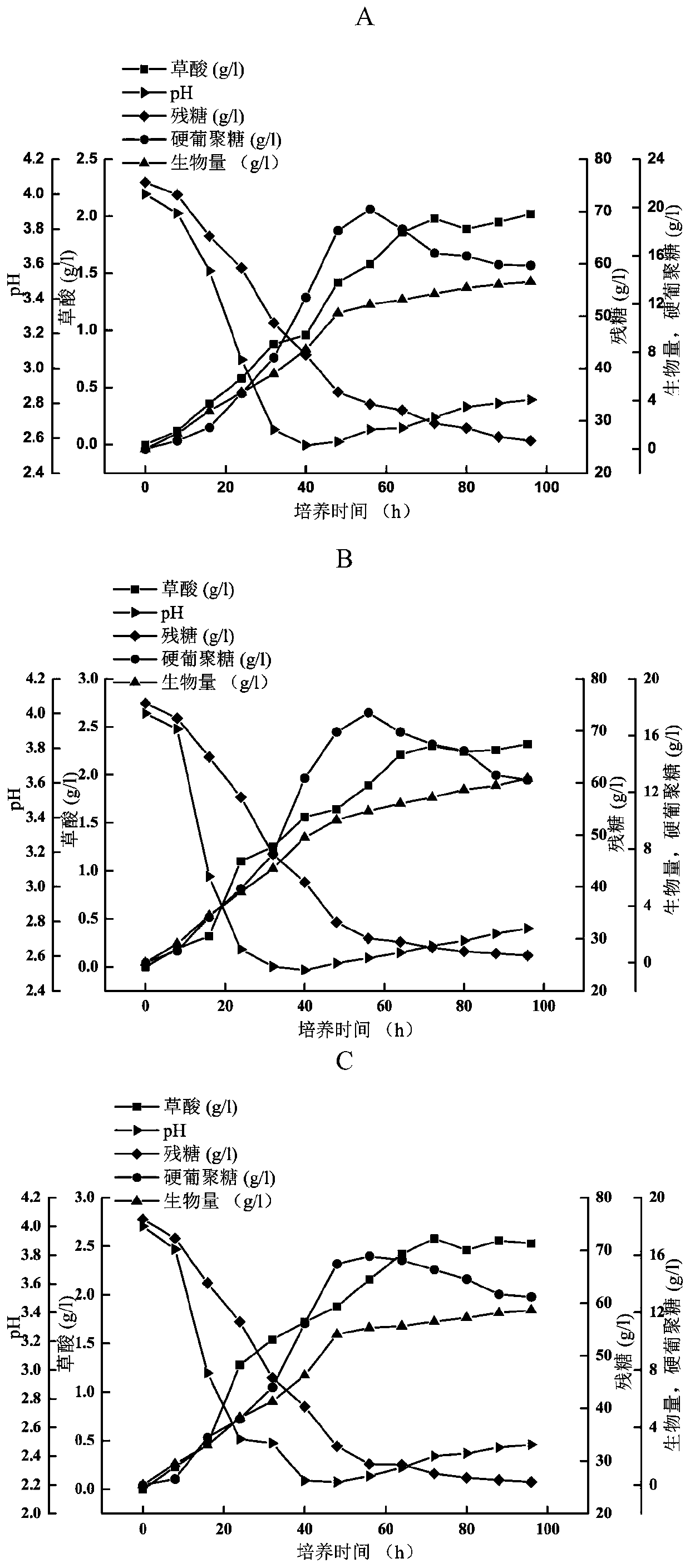

[0033] The impact of embodiment 3 different carbon source concentrations on the production of scleroglucan

[0034] The specific embodiment is the same as Example 2, the difference is that the fermentation medium formula is: sodium nitrate 2.2g / L, yeast extract 0.5g / L, KH2 PO 4 1.0g / L, MgSO 4 ·7H 2 O 0.5g / L, citric acid 1.5g / L, KCl 0.5g / L, pH 4.5; different glucose additions (55, 75, 95g / L) were used to investigate the effect of carbon source on the production of scleroglucan.

[0035] Batch culture in a 3L fermenter: Transfer the above seed solution cultured at 28°C and 220r / min for 72h to a 500ml shake flask with 100ml of seed solution at a 5% inoculum size, and transfer the seed solution at 28°C and 220r / min Cultivate under conditions for 48 hours, and then inoculate 5% inoculum in a 3L fermenter with 1.5L fermentation medium for 96 hours, set the temperature at 30°C, and stir at a speed of 350r / min.

[0036] Fermentation results such as figure 2 As shown, the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com