Sponge brick and preparation method thereof

A technology of sponge bricks and bricks, which is applied to pavement details, buildings, roads, etc., can solve the problems of limited water absorption and water accumulation, and achieve the effects of reducing production costs, strong water absorption, and improving the problem of water accumulation on urban roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

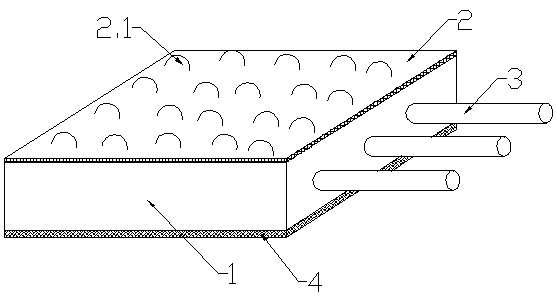

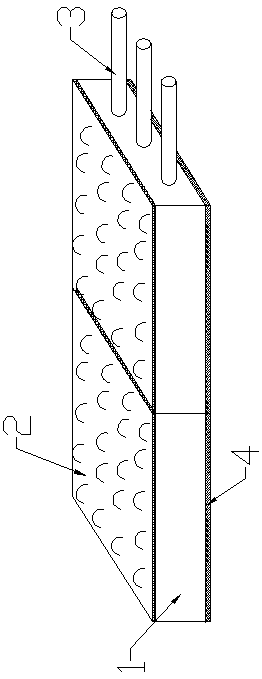

[0025] like Figure 1-2 As shown, the sponge brick of this embodiment includes a sponge brick base 1, and the sponge brick base 1 deposits mesh-like starch granules on the microporous plastic by a liquid phase deposition method, and then presses the microporous plastic with the starch granules deposited on it. It is made by injection molding into a brick body by a conventional method; a foot massage layer 2 made of foam plastic is laid on the top of the sponge brick base 1 in a glued manner, and the top surface of the foot massage layer 2 is integrally formed with a number of elastic protrusions 2.1 adjacent to each other. The foot massage layer 2 between the two protrusions 2.1 is provided with leaking holes that run through the foot massage layer; a plurality of permeation tubes 3 are pre-embedded in the sponge brick matrix 1, and several permeation holes are opened in the permeation tube 3 circumferential direction, and the permeation tubes 3. One end passes through one sid...

Embodiment 2

[0035] The specific structure of the sponge brick in this embodiment is the same as that in Example 1, but the sponge brick matrix is made by adsorbing mesh-like starch particles on the cement-based brick body with micropores by negative pressure method.

[0036] The preparation process of above-mentioned reticular starch granules is:

[0037] In the first step, the starch extracted from starch processing wastewater is soaked in an appropriate amount of 10% sodium hydroxide solution for 10 hours, then ground, and the ground slurry is spray-dried to obtain superfine starch;

[0038] In the second step, pour the superfine starch prepared in the first step into an appropriate amount of deionized water, add α-amylase in an amount of 0.1% of the superfine starch, adjust the pH to 6.2-6.4 with hydrochloric acid, and disperse by ultrasonic for 40 minutes , and then stirred at constant temperature for 0.5h, the reaction was completed, the enzyme was inactivated, and the enzymolyzed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com