Assembly type temporary steel bridge structure and construction method thereof

A prefabricated, steel portable bridge technology, which is applied in basic structure engineering, erection/assembly bridges, portable bridges, etc., can solve problems such as difficulty in ensuring construction quality, damage to pipe pile structures, and easily damaged bridge decks, etc., to improve the use of Range and flexibility, protection of pile foundation structure, effect of improving load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

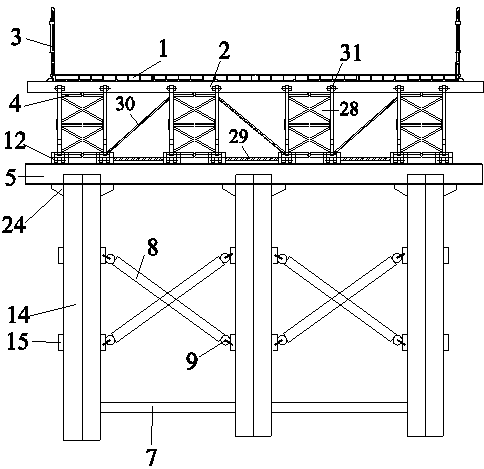

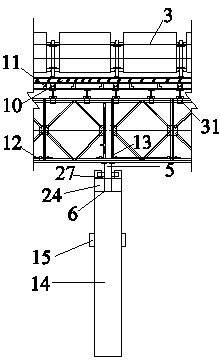

[0039] like Figure 1-9 As shown, the assembled steel temporary bridge structure of the present invention includes steel pipe pile top parallel steel corbel system, Bailey main beam and distribution beam system, assembled integral bridge deck pavement and guardrail system;

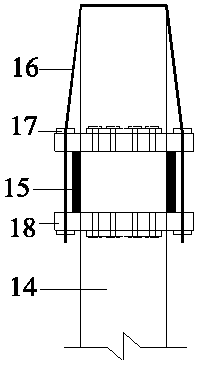

[0040] The steel pipe pile top parallel connection steel corbel system includes a unit type steel horizontal connection frame 8 arranged in the middle of the steel pipe pile 14 and located between two adjacent steel pipe piles 14, and a steel pipe pile near the top of the steel pipe pile 14 Pile top steel corbel 24, steel pipe pile through ear plate 25, corbel reinforcing ring plate 26 and corbel stiffening plate 6 are located at the bottom of steel pipe pile 14 and the pile bottom beam 7 between two adjacent steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com