Anti-explosion mining mechanical brake pad and preparation method thereof

A brake pad and mechanical technology, applied in the field of explosion-proof mine mechanical brake pads and their preparation, can solve the problems of increased friction surface temperature of brake pads and brake discs, safety accidents, etc. Effect of flame retardant and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

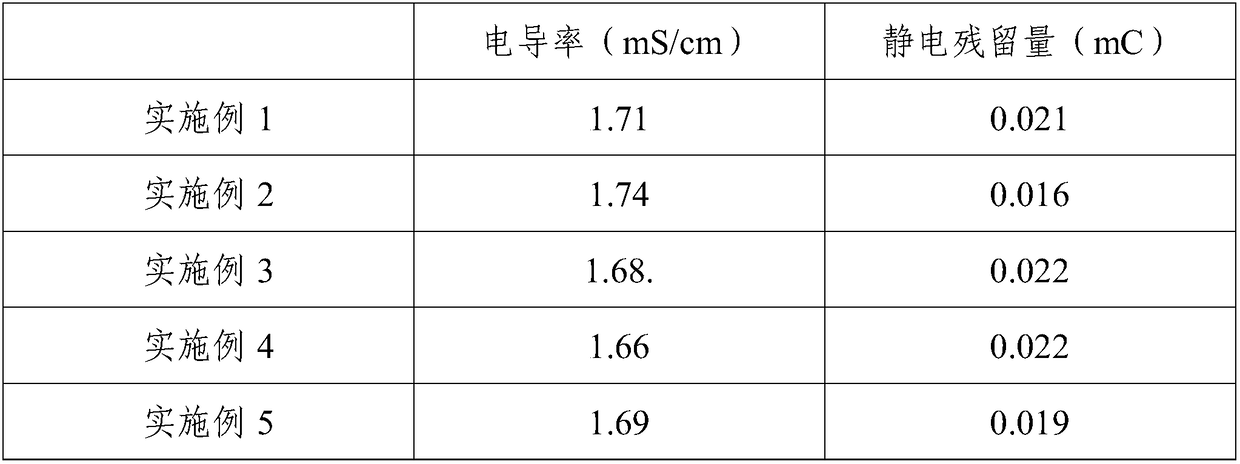

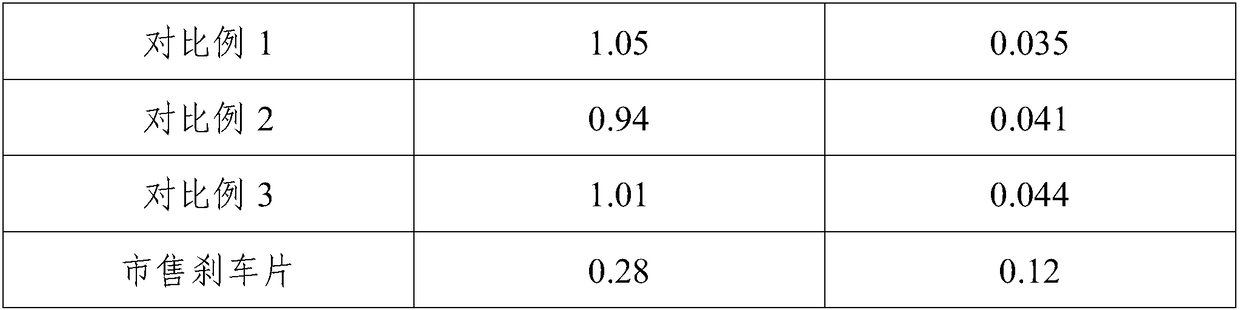

Examples

preparation example Construction

[0026] The preparation method of the mining machinery brake pad comprises the following steps:

[0027] (1) Mixing: weigh each component according to the formula, and mix them evenly in a high-speed mixer;

[0028] (2) Hot pressing molding: take the mixture processed in step (1) and put it into a hot pressing mold for hot pressing molding, and the pressure is 250kg / cm 2 , hot-pressing time 8 minutes, hot-pressing temperature 160 ℃;

[0029] (3) Heat treatment: place the green body after hot pressing in a heat treatment furnace for heat treatment, and adopt a gradient heat treatment system to heat treat the green body. The initial temperature of heat treatment is 120°C, the end temperature is 220°C, and the heating rate is 2°C / min; and when the temperature is 120°C, 130°C, 155°C, 165°C, 180°C, 200°C and 220°C, keep warm for 90 minutes;

[0030] (4) Grinding: Grinding the green body processed through step (3) with an electric grinding head whose rotating speed is 80r / min to o...

Embodiment 1

[0032] An explosion-proof mine mechanical brake pad is prepared from the raw materials of the following formula by weight percentage:

[0033] Chopped glass fiber 20%, aramid fiber 9%, friction powder 6%, petroleum coke powder 4%, flake graphite 10%, magnesium oxide micropowder 7%, barium sulfate 10.5%, carbon black 6%, powdered nitrile rubber 18.5%, anti-aging agent TMQ 0.6%, vulcanization accelerator MBTS 0.4%, high temperature resistant resin 8%.

Embodiment 2

[0035] An explosion-proof mine mechanical brake pad is prepared from the raw materials of the following formula by weight percentage:

[0036] Chopped glass fiber 12%, aramid fiber 10%, friction powder 8%, petroleum coke powder 3%, flake graphite 9%, magnesium oxide micropowder 6%, barium sulfate 11%, carbon black 6%, powdered nitrile rubber 24%, anti-aging agent TMQ 1.5%, vulcanization accelerator MBTS 0.5%, high temperature resistant resin 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com