Electrical bistable characteristics-based single-layer polymer electric memory and manufacturing method thereof

A technology of electrical memory and photoelectric polymer, which is applied in the manufacture of semiconductor/solid-state devices, electrical solid-state devices, circuits, etc., can solve the problems of difficulty in realizing large-area flexible storage, unfavorable environmental impact, and high manufacturing costs, and achieve large-area flexibility. The effect of storage, simple process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

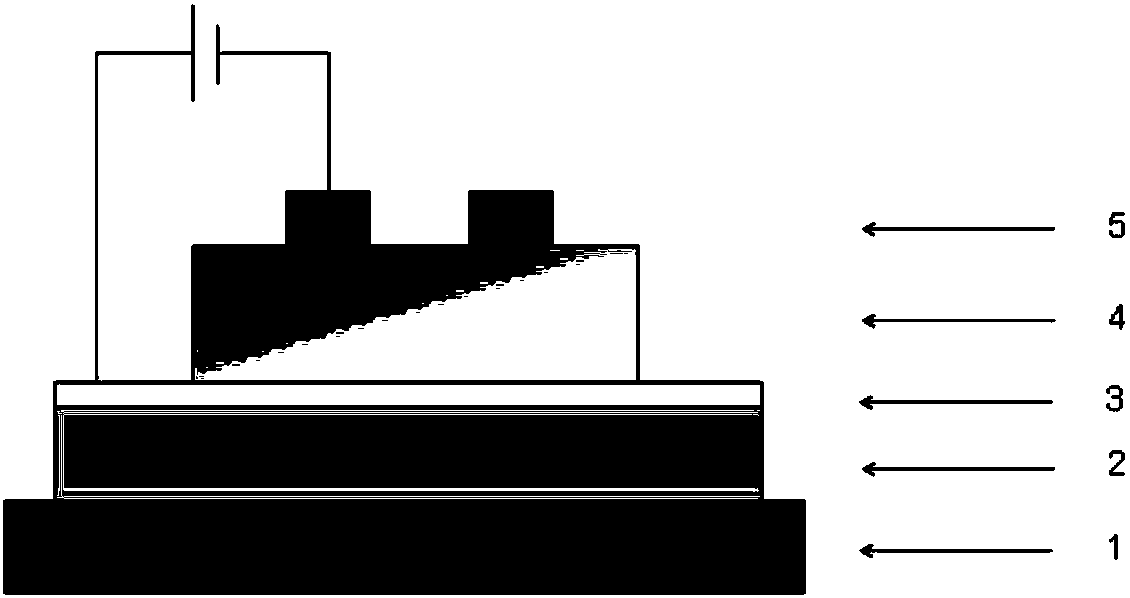

[0042] First, the ITO on the ITO glass is photolithographically formed into electrodes with a width of 4 mm and a length of 30 mm, and then ultrasonically cleaned with acetone, isopropanol, glass cleaner, and deionized water, and dried with nitrogen. Plasma treatment for 4-10 minutes. Spin-coat PEDOT:PSS polymer aqueous solution on the cleaned ITO electrode, and vacuum bake at a constant temperature of 50-150°C for 0.5-3 hours to form a hole injection layer (also known as an anode buffer layer). PEDOT:PSS is mainly used to modify the ITO electrode and form the real anode of the device together with ITO. Then spin-coat the photoelectric polymer MEH-PPV xylene solution on the well-formed PEDOT:PSS, and vacuum bake at a constant temperature of 50-200°C for 10-40 minutes to form a photoelectrically active functional layer with a smooth surface and no defects. Finally, transfer the sample to the coating equipment, in a vacuum of (1-5)×10 -4 Under the condition of Pa, the metal Au...

Embodiment 2

[0046] The process and parameters of embodiment 2 are basically the same as those of embodiment 1, except that the top electrode is replaced by 50-300nm Au with 50-300nm Al.

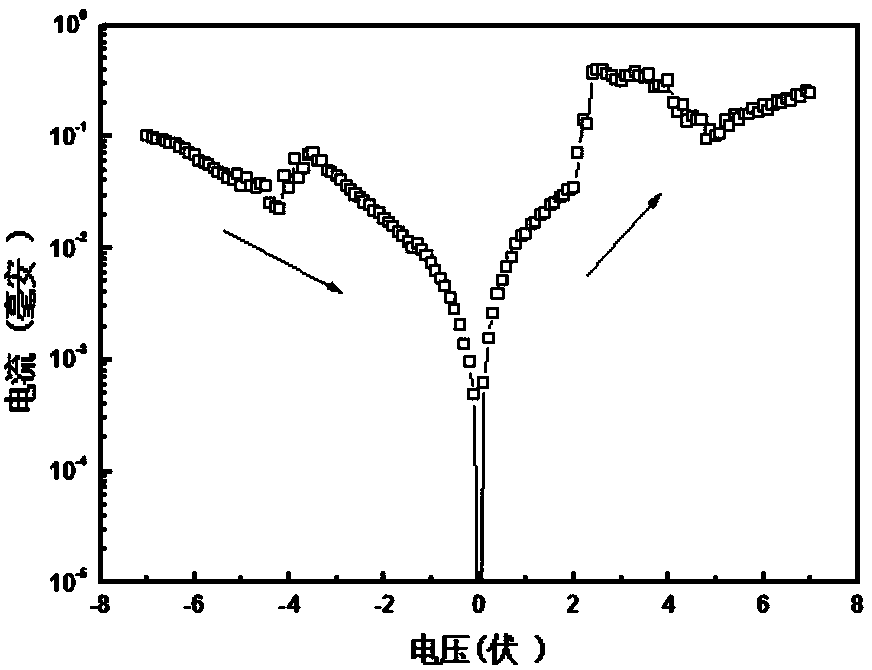

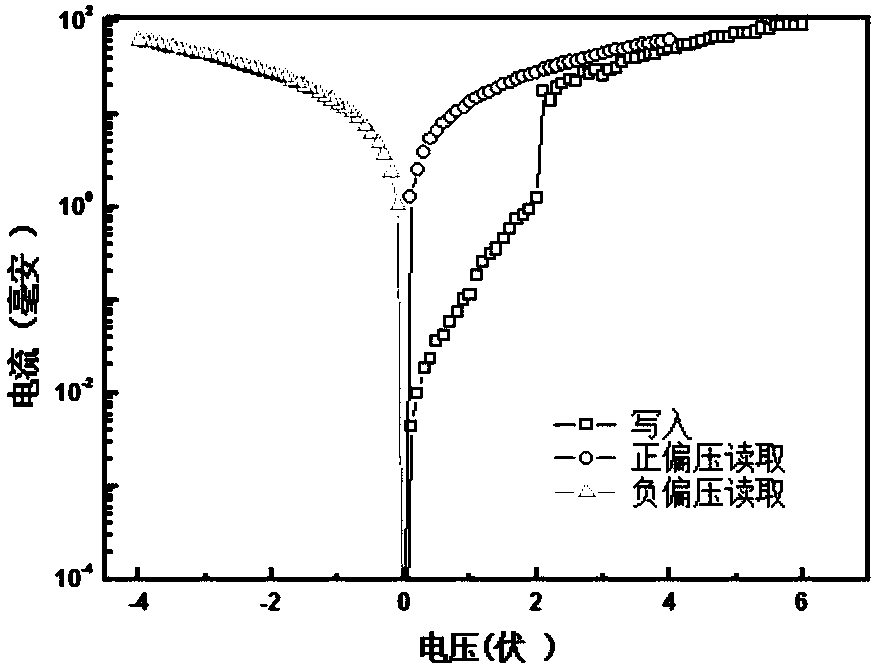

[0047] The memory has an effective area of 16 square millimeters. Figure 4 Its typical and representative current and voltage scanning characteristic curves are given. It can be seen from the figure that the device also exhibits a sudden change in current when scanning from negative to positive. This sudden change in current can be used in the manufacture of electrical switching memory devices.

[0048] Figure 5 A description of the data read and write process of the device is given, and the current switch ratio is 90. Under normal temperature and pressure, the current of a simple packaged device does not change significantly even if it is switched more than one million times.

Embodiment 3

[0050] The process and parameters of embodiment 3 are basically the same as those of embodiment 1, except that the top electrode is replaced by 50-300nm Au with 10-50nm Ba and 40-250nm Al, wherein the evaporation rate of Ba is controlled at 0.1 -0.5 nm / s, the evaporation rate of Al is controlled at 0.2-2 nm / s.

[0051] The memory has an effective area of 16 square millimeters. Figure 6 The typical representative current-voltage sweep characteristic curve of the polymer electrical storage device is given. It can be seen from the figure that: the voltage sweep changes from negative bias to positive bias, and then back to negative bias, and the device shows a sudden change in current.

[0052] Figure 7 A description of the current-voltage relationship before and after the abrupt change of the device current is given. Taking the negative bias interval as an example, the logarithm of the current and voltage in the high conductance state presents a linear relationship with a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com