A Switched Reluctance Generator High Voltage DC Unit Converter System

A reluctance generator and switched reluctance technology, which is applied in the direction of controlling the generator through the change of the magnetic field, the control of the generator, the control system, etc., can solve the problems of large fluctuations in excitation power, large output voltage and current adjustment ranges, and complex structures. problem, achieve the effect of reducing the burden of rectification, stabilizing the current waveform, and enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

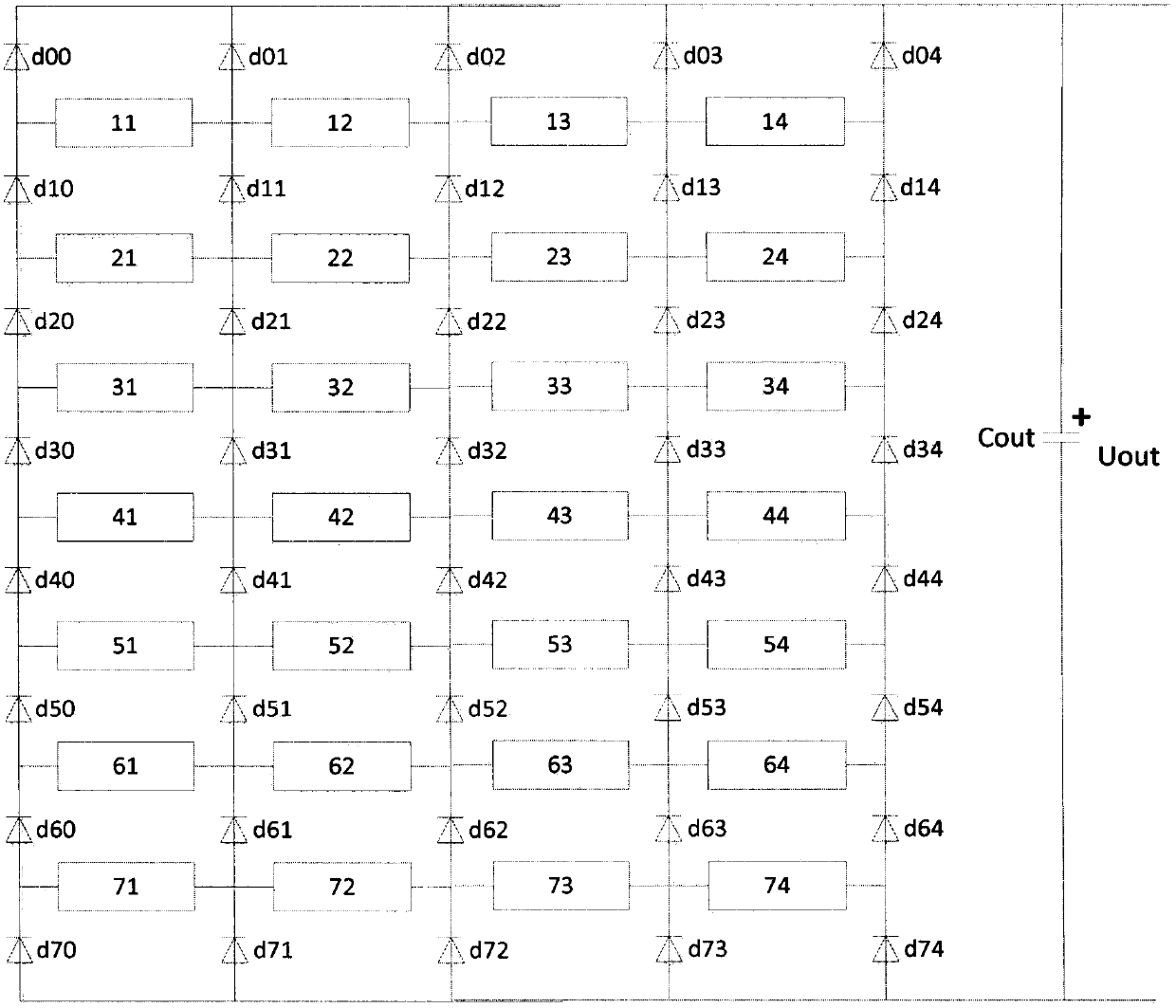

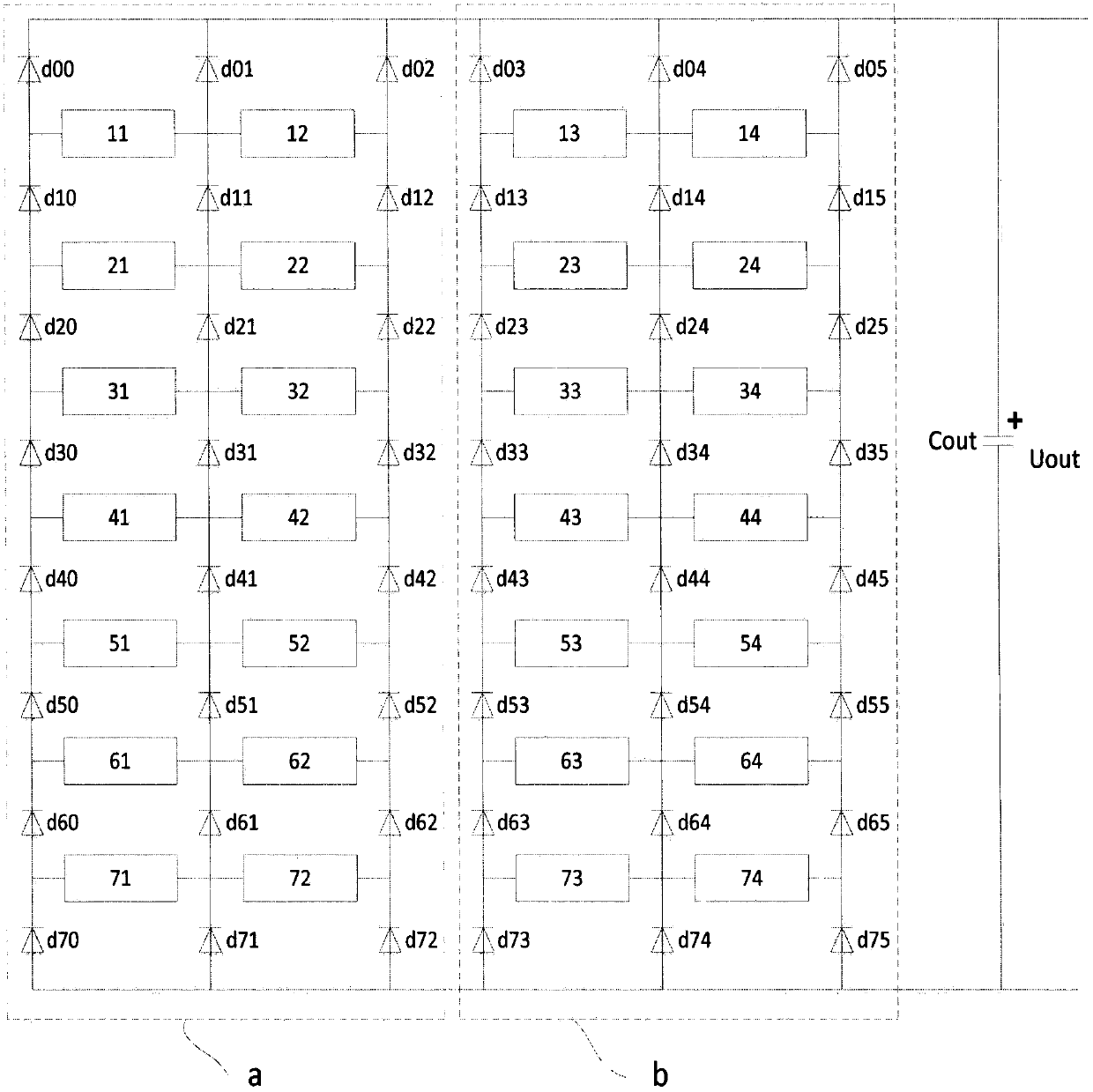

[0050] The switched reluctance generator of this embodiment is a four-phase winding, which is respectively M / N / P / Q four-phase windings according to the order distributed on the stator; as attached figure 1 As shown, the four-phase winding of the switched reluctance generator is connected to the winding converter circuit 1 , and the power required for the excitation stage comes from the feedback power supply 3 .

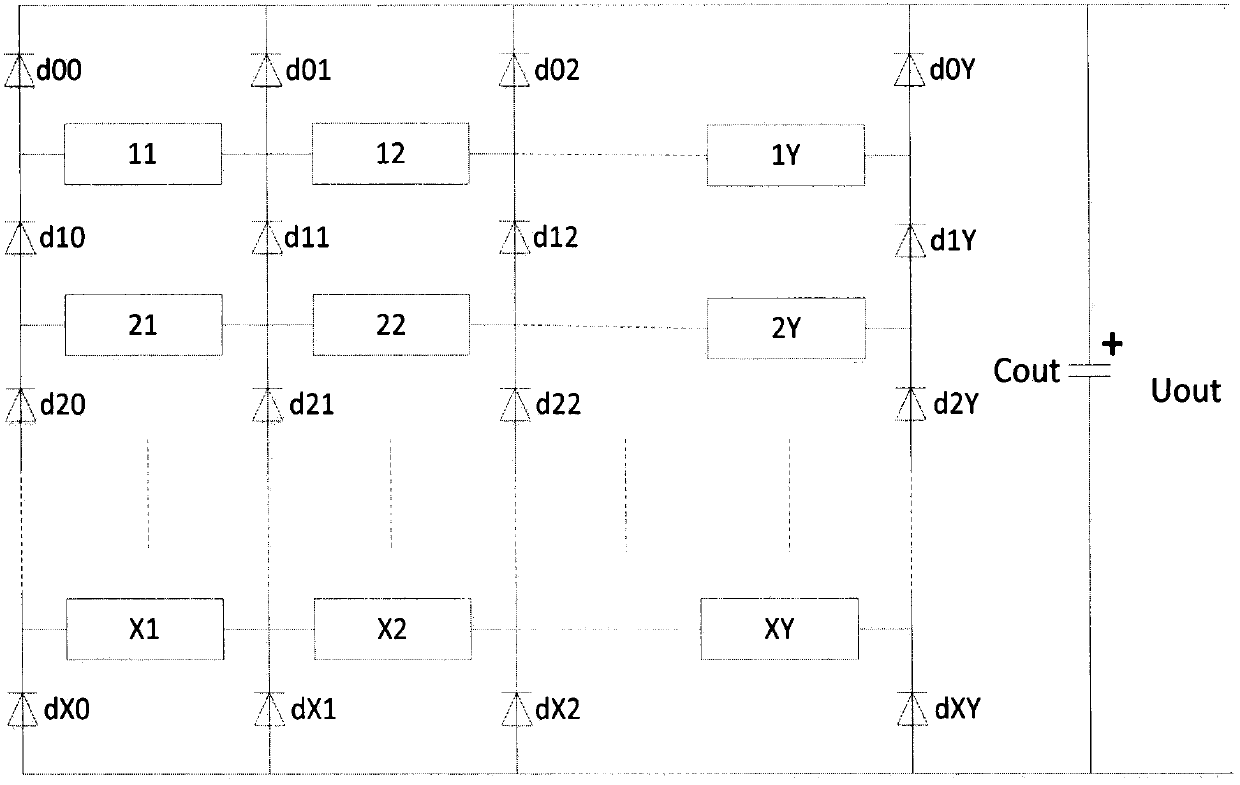

[0051] A switched reluctance generator high-voltage DC unit conversion system, which is composed of a single-switch reluctance generator unit conversion circuit and a multi-unit power convergence network, and each single-switch reluctance generator unit conversion circuit in the multi-unit power convergence network The structure of the switched reluctance generator and the inverter circuit are the same.

[0052] The converter circuit of the single-switch reluctance generator set is composed of a winding converter circuit 1, an inverter circuit 2, and a feedback power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com