Instant dandelion beverage and preparation method thereof

A dandelion, instant technology, applied in food preservation, food drying, food freezing, etc., can solve the problems of not prominent flavor, weaken the efficacy of dandelion, and achieve the natural effect of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

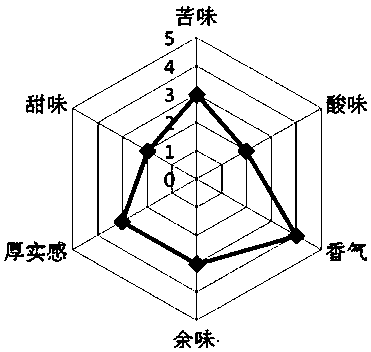

Embodiment 1

[0030] Manually screen the dandelion raw materials, separate the aerial parts and roots, remove impurities, compound according to 30wt% aerial parts and 70wt% roots; turn on the rotary roaster, preheat to 180°C, and put the compounded dandelion raw materials into baking Machine, the baking temperature is 160°C, bake for 25min, then gradually raise the temperature to 190°C, keep for 90s, quickly unload and quickly air-cool, then crush until the output particle size D50 value is 5mm; put it into the extraction kettle, inject the material 4 times the weight of water at 95°C, control the extraction temperature at 90°C, stir and extract for 20 minutes, release the dandelion extract ①, then inject 90°C water twice the weight of the material, control the extraction temperature at 90°C, stir and extract for 10 minutes, and release the dandelion extract Liquid ②, combined extract ① and extract ②, passed through a cloth bag filter, filtered while hot, and the filtrate was injected into a...

Embodiment 2

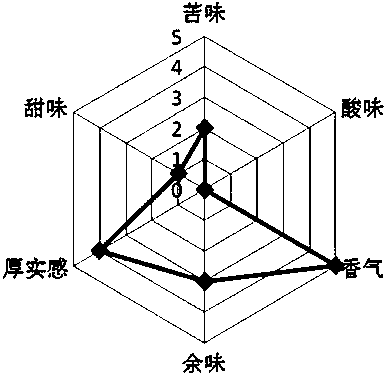

[0032] The dandelion raw materials are manually screened, the above-ground parts and roots are separated, impurities are removed, and thicker and more consistent dandelion roots are selected through a color sorter. Turn on the rotary roaster, preheat it to 180°C, put the dandelion root into the roaster at a temperature of 170°C, bake for 30 minutes, then gradually raise the temperature to 210°C, keep it for 60 seconds, quickly unload and quickly air Cool, then, crush until the discharge particle size D50 value is 2mm; put it into the extraction kettle, inject superheated water 6 times the weight of the material, control the extraction temperature at 95 ° C, stir and extract for 30 minutes, release the dandelion extract ①, and then inject the weight of the material 3 times of 90°C water, control the extraction temperature at 90°C, stir and extract for 15 minutes, release the dandelion extract ②, combine the extract ① and extract ②, pass through a cloth bag filter, filter while h...

Embodiment 3

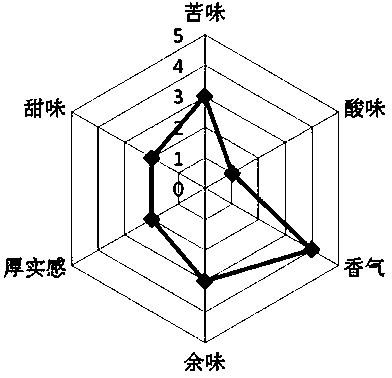

[0034] Manually screen the dandelion raw materials, separate the aerial parts and roots, remove impurities, compound according to 65wt% aerial parts and 35wt% roots, turn on the rotary roaster, preheat to 180°C, and put the matched dandelion raw materials into the roaster , the baking temperature is 150°C, bake for 20min, then gradually increase the temperature to 190°C, keep for 30s, quickly unload and quickly air-cool, then crush until the discharge particle size D50 value is 5mm, put it into the extraction kettle, and inject the weight of the material 5 times the water at 90°C, control the extraction temperature at 90°C, stir and extract for 20 minutes, release the dandelion extract ①, then inject 85°C water with 1 times the weight of the material, control the extraction temperature at 85°C, stir and extract for 10 minutes, and release the dandelion extract ②, combine the extract ① and the extract ②, pass through a cloth bag filter, filter while hot, inject the filtrate into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com