Device and method used for plasma cooperative electric cartridge heater screen catalytic treatment of VOCs

A plasma and catalytic treatment technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of secondary pollution, production of toxic substances, etc., and achieve the advantages of low treatment cost, high removal efficiency, and improved degradation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

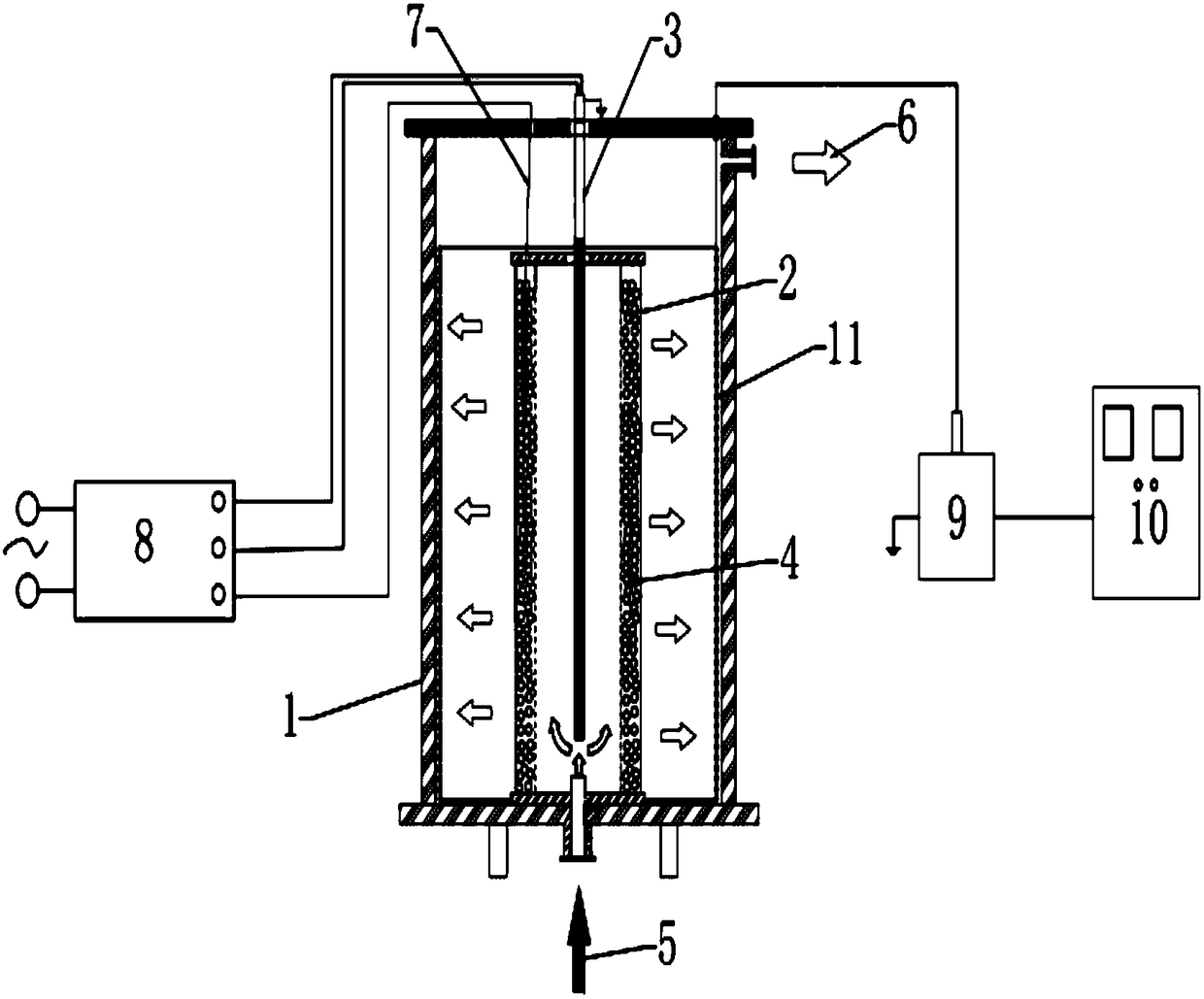

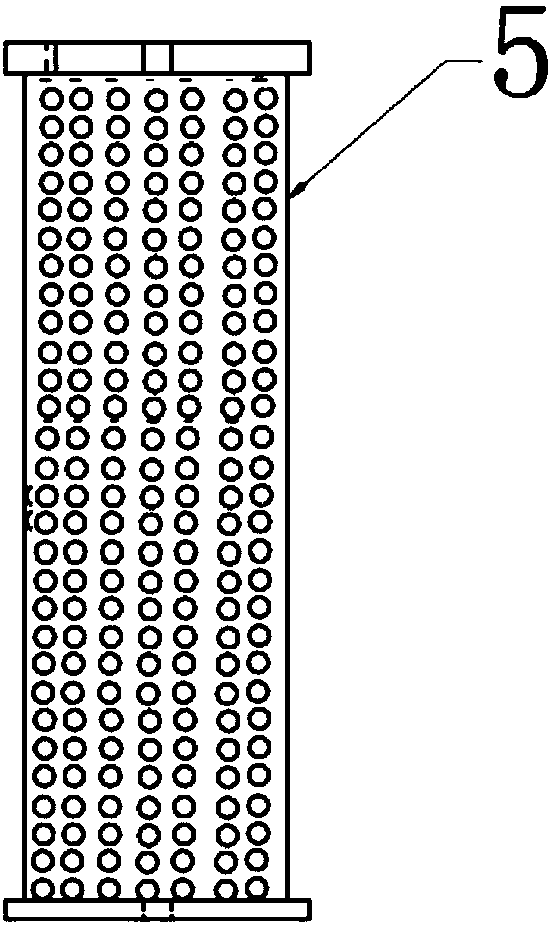

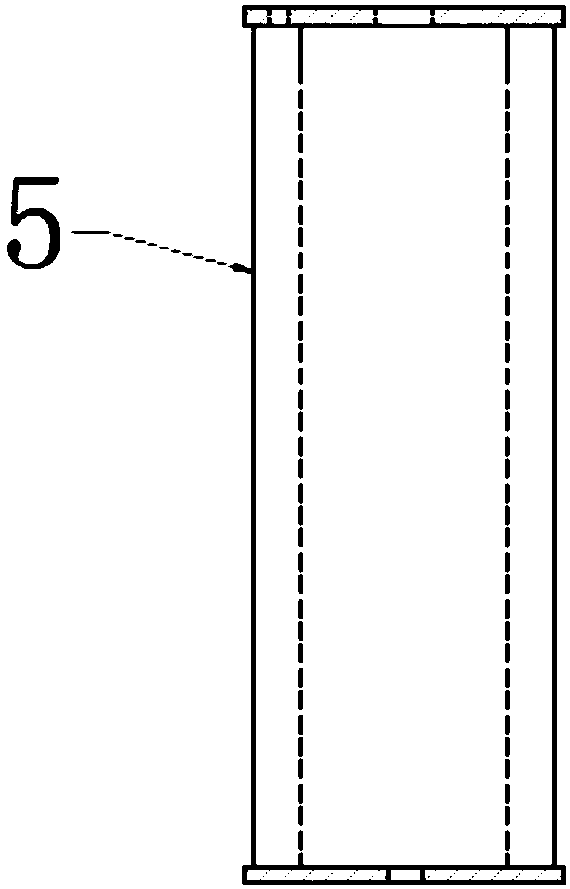

[0058] Such as Figure 1~4 As shown, the device for catalytic treatment of VOCs with plasma and electric heating cylinder net of this embodiment includes: a reaction chamber, a double-layer filter cylinder 2, an infrared radiation heating tube 3, and a structure 11 of a net cylinder discharge electrode.

[0059] The reaction chamber is cylindrical. The cylinder includes a cylinder body 1 and two end covers that seal the cylinder body. The two ends of the infrared radiation heating tube 3 are fixed on the corresponding end cover, and the end cover has a thermocouple 7 socket . The reaction chamber is provided with an exhaust gas inlet 5 and an exhaust gas outlet 6. The double-layer filter cylinder 2 is installed in the central part of the reaction chamber, and the infrared radiation heating tube 3 is inserted in the axial center of the double-layer filter cylinder 2; the catalyst 4 is filled in the double-layer filter The middle of the interlayer of the mesh cylinder 2; the infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com