Seal head welding machining tool of liquid ammonia tank

A liquid ammonia tank and head technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of no one designing and processing tooling, low overall efficiency, etc., to reduce repair welding work, improve work efficiency, The effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

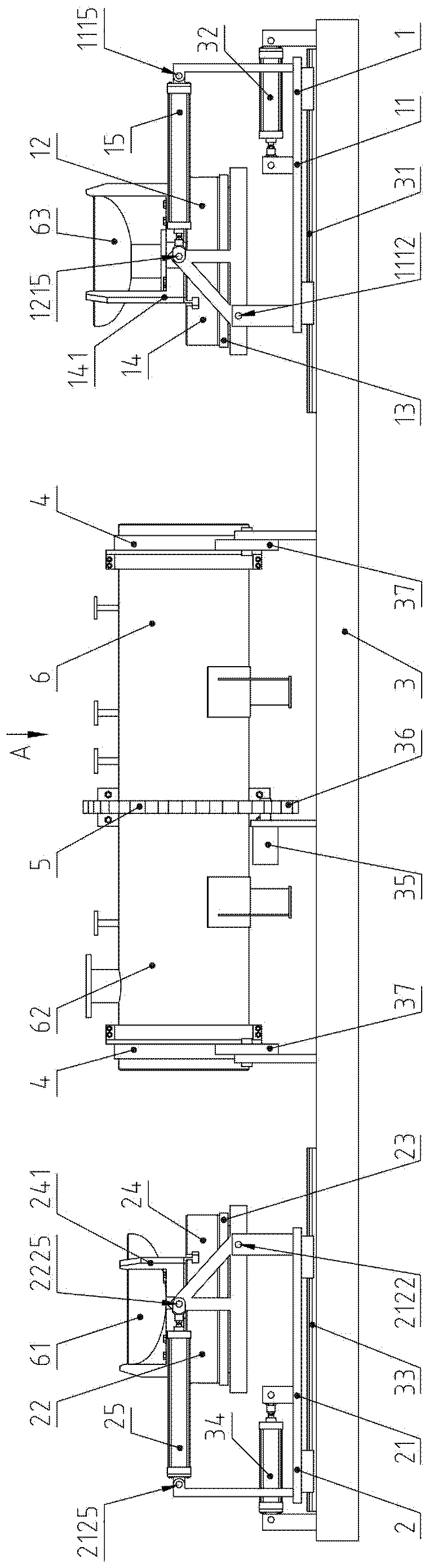

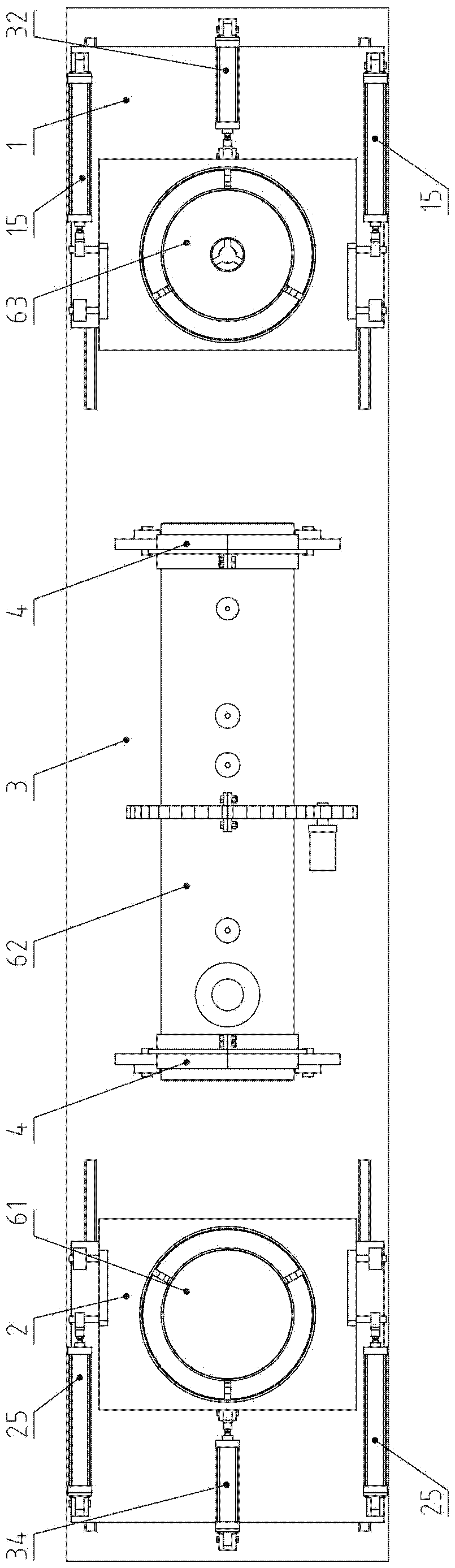

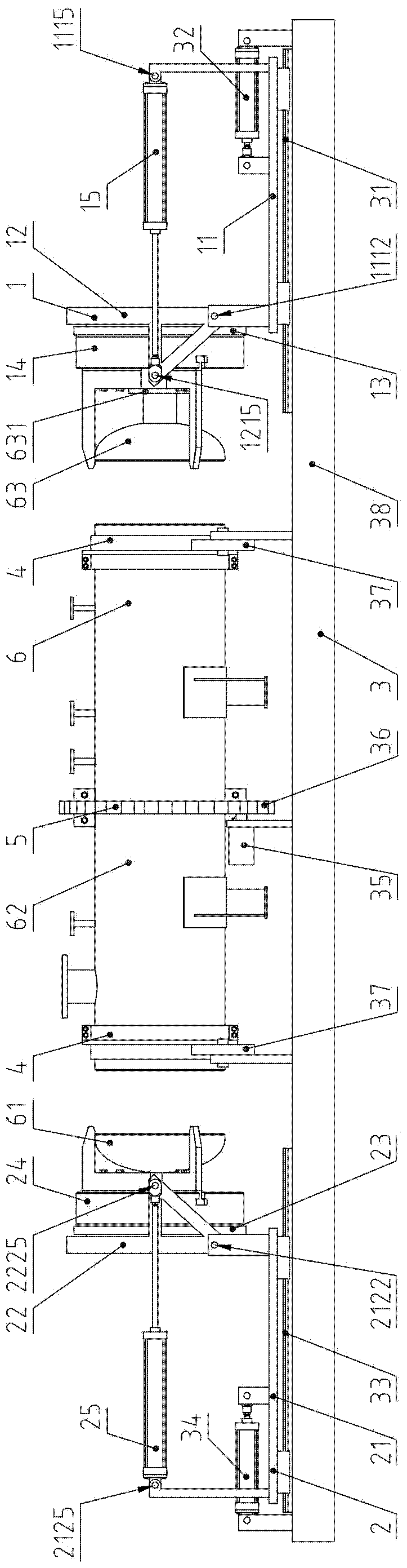

[0049] Example: see Figure 1 to Figure 14 .

[0050] A head welding processing tool for a liquid ammonia tank, comprising a right positioning component 1, a left positioning component 2, a base component 3, four half-ring tracks 4 and two half-ring gear rings 5;

[0051] The base assembly 3 includes a right linear guide rail 31, a right translation cylinder 32, a left linear guide rail 33, a left translation cylinder 34, a servo motor 35, a drive gear 36, a passive runner 37 and a base 38; two right linear guide rails 31 are fixedly connected in parallel At the right end of base 38, right linear guide rail 31 is arranged left and right; Two left linear guide rails 33 are fixedly connected to the left end of the base 38 in parallel, and the left linear guide rails 33 are arranged in the left and right direction; , the middle of the two left linear guide rails 33;

[0052] The right positioning assembly 1 comprises a right carriage assembly 11, a right turning frame 12, a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com