Graphene film rolled materials and preparation method thereof

A graphene film roll and graphene film technology are applied in the preparation of graphene film roll materials, graphene film roll materials and their preparation fields, and can solve problems such as graphene product bottlenecks, supply chain shortages, electromagnetic wave pollution, and the like, Achieve the effect of stable product quality, easy operation and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

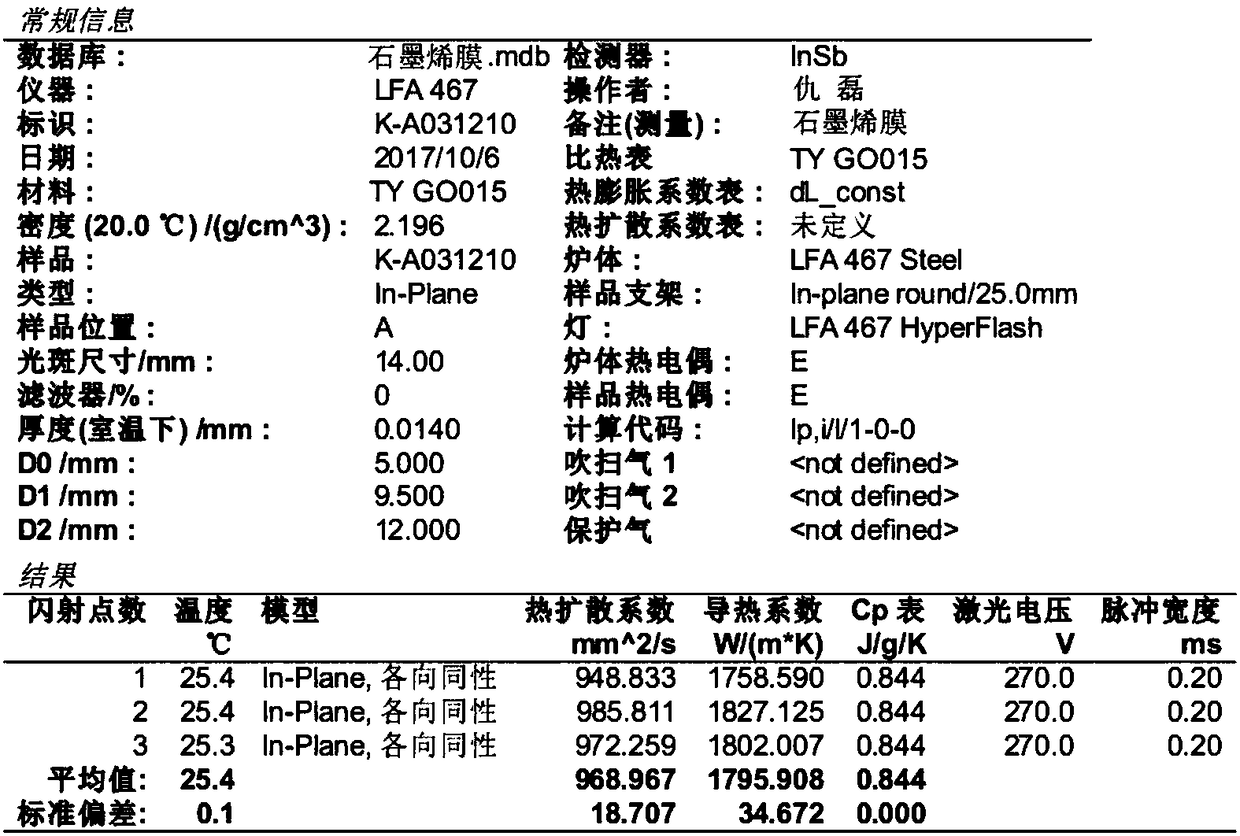

[0021] The preparation of embodiment 1 TYGO-015JC model product

[0022] A method for preparing a graphene film roll material, comprising the following steps:

[0023] a) ultrasonic immersion and stirring of graphene oxide in water;

[0024] B) Graphene oxide solution is coated on the PI film, dry continuously, obtain the rolled graphene film base material that removes PI film;

[0025] c) Carry out high-temperature carbonization with the roll-shaped graphene film base material in a sintering furnace by temperature programming to form a graphene film bubble-like coil;

[0026] D) Graphene film foamed roll material is placed in a high-temperature furnace for graphitization, and the graphene film substrate is obtained by cooling after graphene is completed;

[0027] E) and the graphene film substrate product that step d) obtains is taken out, after the graphene film substrate product is carried out calendering with calender, finally produce the graphene film of roll shape.

...

Embodiment 2

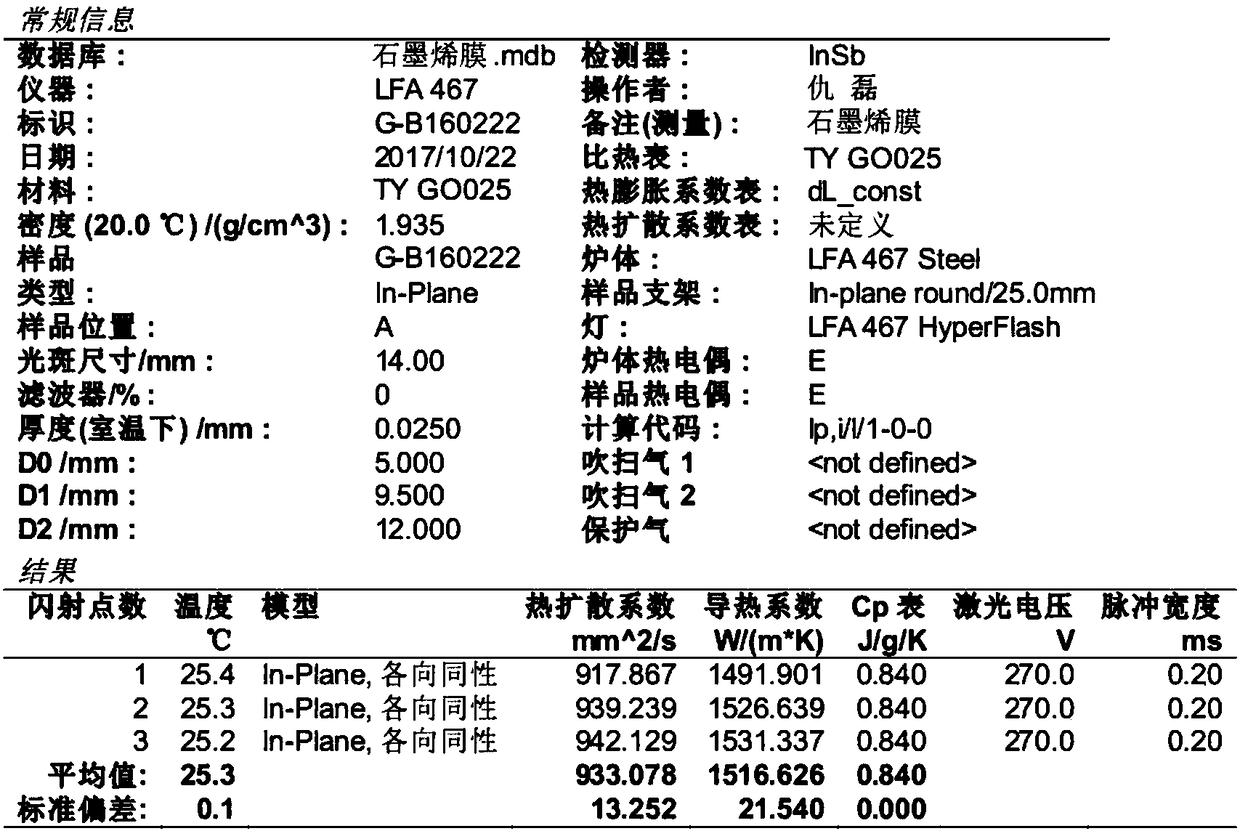

[0033] The preparation of embodiment 2 TYGO-025J model product

[0034] A method for preparing a graphene film roll material, comprising the following steps:

[0035] a) ultrasonic immersion and stirring of graphene oxide in water;

[0036] B) Graphene oxide solution is coated on the PI film, dry continuously, obtain the rolled graphene film base material that removes PI film;

[0037] c) Carry out high-temperature carbonization with the roll-shaped graphene film base material in a sintering furnace by temperature programming to form a graphene film bubble-like coil;

[0038] D) Graphene film foamed roll material is placed in a high-temperature furnace for graphitization, and the graphene film substrate is obtained by cooling after graphene is completed;

[0039] E) and the graphene film substrate product that step d) obtains is taken out, after the graphene film substrate product is carried out calendering with calender, finally produce the graphene film of roll shape.

[...

Embodiment 3

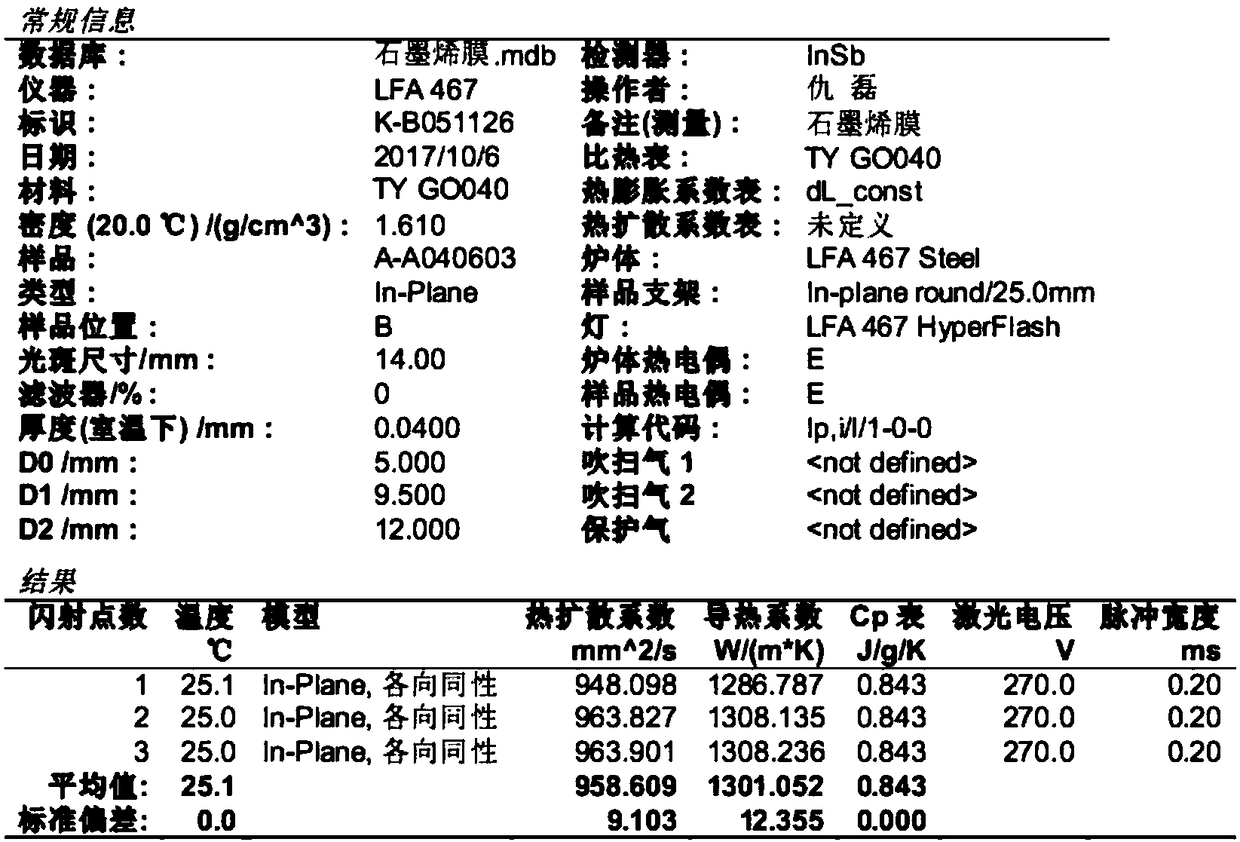

[0045] Embodiment 3 Preparation of TYGO-040J model product

[0046] A method for preparing a graphene film roll material, comprising the following steps:

[0047] a) ultrasonic immersion and stirring of graphene oxide in water;

[0048] B) Graphene oxide solution is coated on the PI film, dry continuously, obtain the rolled graphene film base material that removes PI film;

[0049] c) Carry out high-temperature carbonization with the roll-shaped graphene film base material in a sintering furnace by temperature programming to form a graphene film bubble-like coil;

[0050] D) Graphene film foamed roll material is placed in a high-temperature furnace for graphitization, and the graphene film substrate is obtained by cooling after graphene is completed;

[0051] E) and the graphene film substrate product that step d) obtains is taken out, after the graphene film substrate product is carried out calendering with calender, finally produce the graphene film of roll shape.

[0052] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com