Method for preparing two-dimensional inorganic perovskite negative electrode material by solid-liquid phase reaction

A negative electrode material and liquid phase reaction technology, which is applied in the field of solid-liquid phase reaction to prepare two-dimensional inorganic perovskite negative electrode materials, can solve the problems of high cost and complicated preparation process, and achieve the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a two-dimensional inorganic perovskite negative electrode material by solid-liquid phase reaction, comprising the following steps:

[0026] S1. Add lead bromide and cesium bromide in a molar ratio of 1:1 to N,N-dimethylformamide, heat to 68°C, stir for 2.2 hours, and dry in vacuum to obtain a yellow precursor powder CsPbBr 3 ;

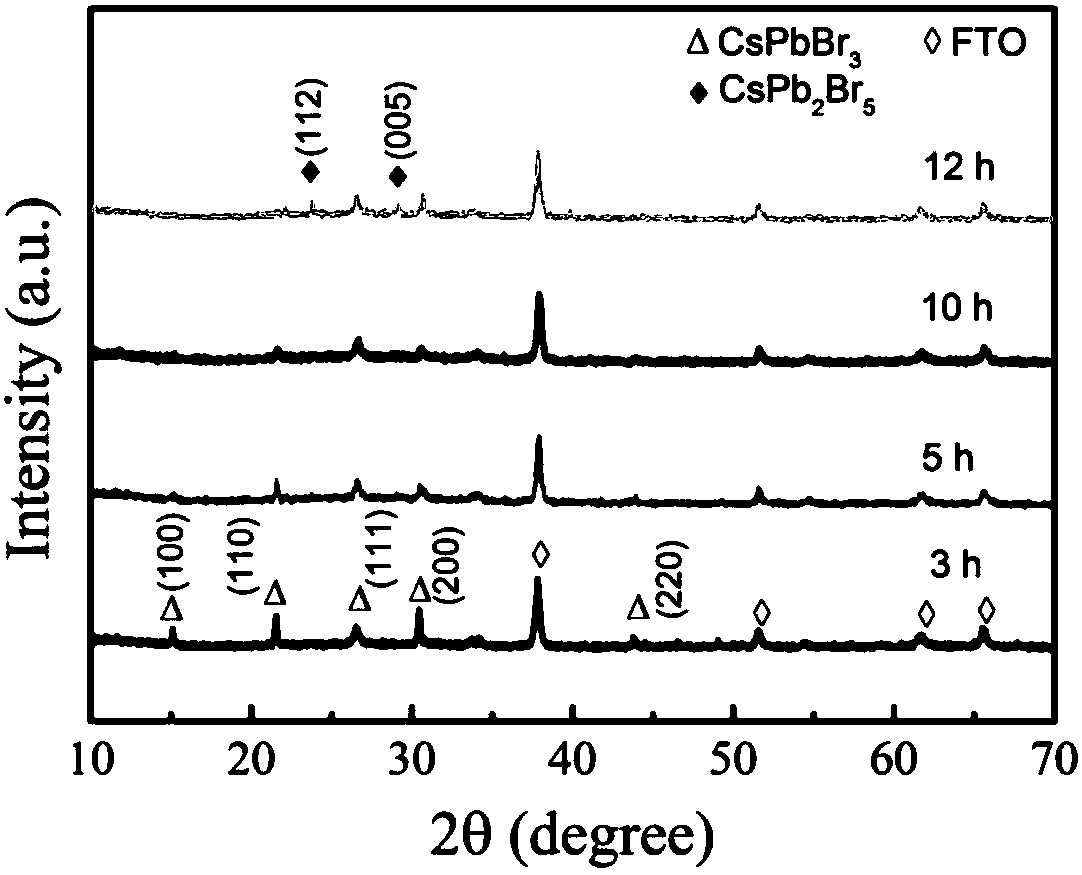

[0027] S2, the precursor powder CsPbBr 3 After mixing with lead bromide at a molar ratio of 1:1, ball milling for 10 hours, the grinding ball and the precursor powder CsPbBr 3 The ball-to-material ratio is 11:1, the ball milling speed is 3000r / min, grinding for 3h, and vacuum drying at 119°C for 2.2h to obtain a two-dimensional inorganic perovskite negative electrode material.

Embodiment 2

[0029] A method for preparing a two-dimensional inorganic perovskite negative electrode material by solid-liquid phase reaction, comprising the following steps:

[0030] S1. Add lead bromide and cesium bromide in a molar ratio of 1:1 to N,N-dimethylformamide, heat to 72°C, stir for 1.6h, and dry in vacuum to obtain a yellow precursor powder CsPbBr 3 ;

[0031] S2, the precursor powder CsPbBr 3 After mixing with lead bromide at a molar ratio of 1:1, ball milled for 14 hours, the ball and precursor powder CsPbBr 3 The ball-to-material ratio is 9:1, the ball milling speed is 4000r / min, grinding for 2h, and vacuum drying at 122°C for 1.8h to obtain a two-dimensional inorganic perovskite negative electrode material.

Embodiment 3

[0033] A method for preparing a two-dimensional inorganic perovskite negative electrode material by solid-liquid phase reaction, comprising the following steps:

[0034] S1. Add lead bromide and cesium bromide in a molar ratio of 1:1 to N,N-dimethylformamide, heat to 70°C, stir for 2 hours, and dry in vacuum overnight to obtain a yellow precursor powder CsPbBr 3 ;

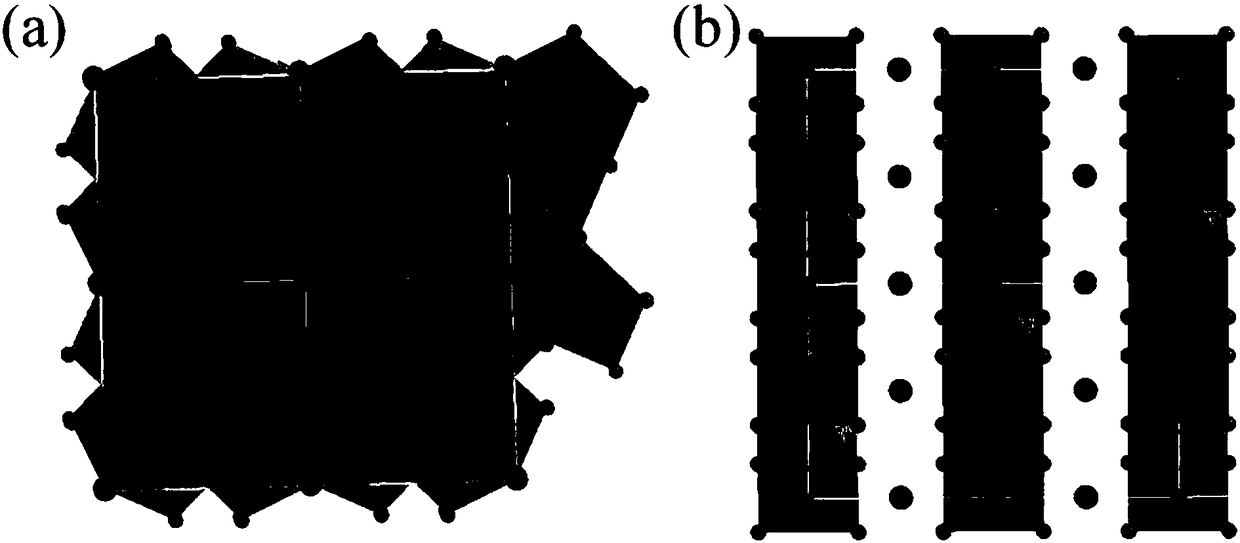

[0035] S2, the precursor powder CsPbBr 3 Mix it with lead bromide at a molar ratio of 1:1, add it to a clean agate ball mill jar, and press the ball and precursor powder CsPbBr 3 The ball-to-material ratio is 10:1, add agate balls, and seal and fix the agate tube in the planetary ball mill. The planetary ball mill rotates the ball at a speed of 3500r / min for 12 hours. The ball milling reaction process maintains a dry environment. In the process, the precursor powder CsPbBr was made 3 It can fully contact and react with lead bromide; then place it in an agate mortar and grind for 2.5 hours, and dry it in vacuum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com