Green recycling method for steel pickling waste liquor

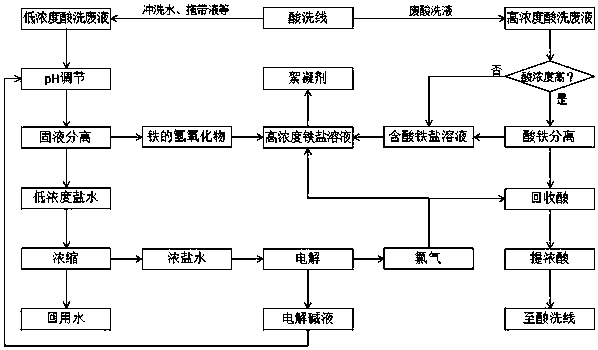

A technology of iron and steel pickling waste liquid and pickling waste liquid, which is applied in the direction of iron oxide/hydroxide, iron halide, chlorine/hydrogen chloride, etc., which can solve the problem of high hazard, large consumption of chemicals, high cost of chemicals and solid waste treatment and other issues to achieve the effects of reducing emissions, improving utilization, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cutting steel wire pickling workshop in Jiangsu produces about 160 tons of pickling waste liquid every day, including 10 tons of waste pickling liquid and 150 tons of flushing waste water. The hydrochloric acid concentration in the waste pickling liquid is 12.8%, and the total iron concentration is 78.7 g / L; the hydrochloric acid concentration in the flushing wastewater is 0.35%, and the total iron concentration is 1.87g / L.

[0031] Adopt the method among the present invention to utilize above-mentioned pickling waste liquid, the steps are as follows:

[0032] 1) Use liquid caustic soda (30wt%) to neutralize and rinse the wastewater, and adjust the pH value to above 8.5. The ferrous hydroxide precipitate produced by the reaction is separated by settling in a sedimentation tank, and then filtered with a diaphragm filter press to obtain low-concentration brine And filter cake; filter cake contains ferrous hydroxide, ferrous hydroxide and about 50% water, low concentrati...

Embodiment 2

[0042] A steel pipe pickling workshop in Jiangsu produces about 130 tons of pickling waste liquid every day, including 15 tons of waste pickling liquid and 115 tons of flushing waste water. The concentration of hydrochloric acid in the waste pickling liquid is 2.51%, and the concentration of total iron is 191.8 g / L; the concentration of hydrochloric acid in the flushing wastewater is 0.07%, and the concentration of total iron is 4.3 g / L.

[0043] Adopt the method among the present invention to utilize above-mentioned pickling waste liquid, the steps are as follows:

[0044] 1) Use liquid caustic soda (30wt%) to neutralize and rinse the wastewater, and adjust the pH value to above 8.5. The ferrous hydroxide precipitate produced by the reaction is separated by settling in a sedimentation tank, and then filtered with a diaphragm filter press to obtain low-concentration brine And filter cake; filter cake contains ferrous hydroxide, ferrous hydroxide and about 50% water, low concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com