Conductive Adhesive Composition

A conductive and adhesive technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve problems such as the decline of adhesion, achieve inhibition of yellowing, high heat resistance, high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

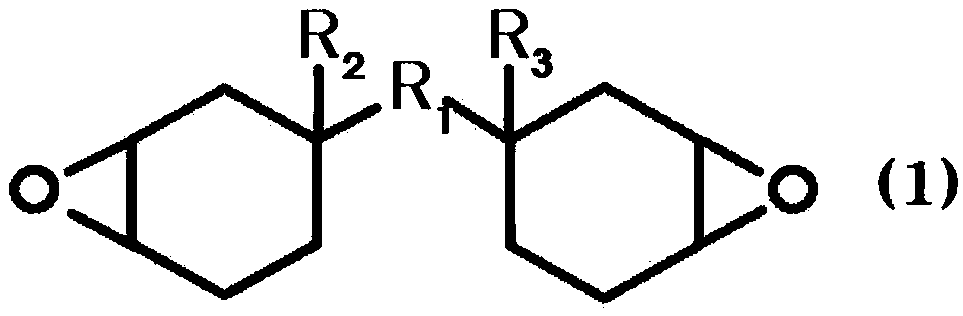

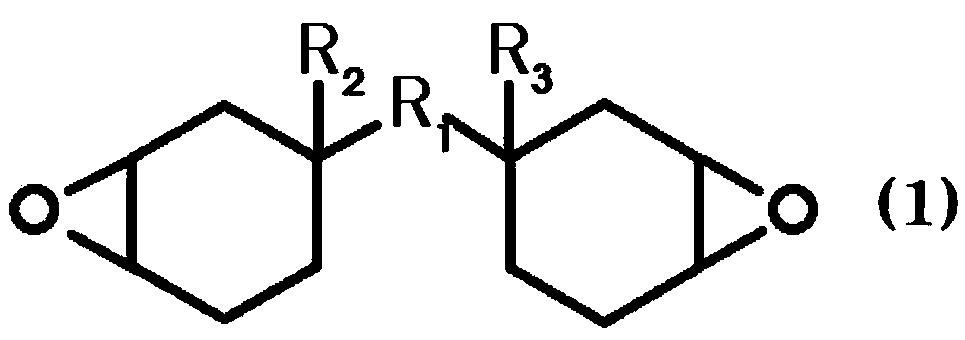

Method used

Image

Examples

Embodiment 1~17 and comparative example 1~2

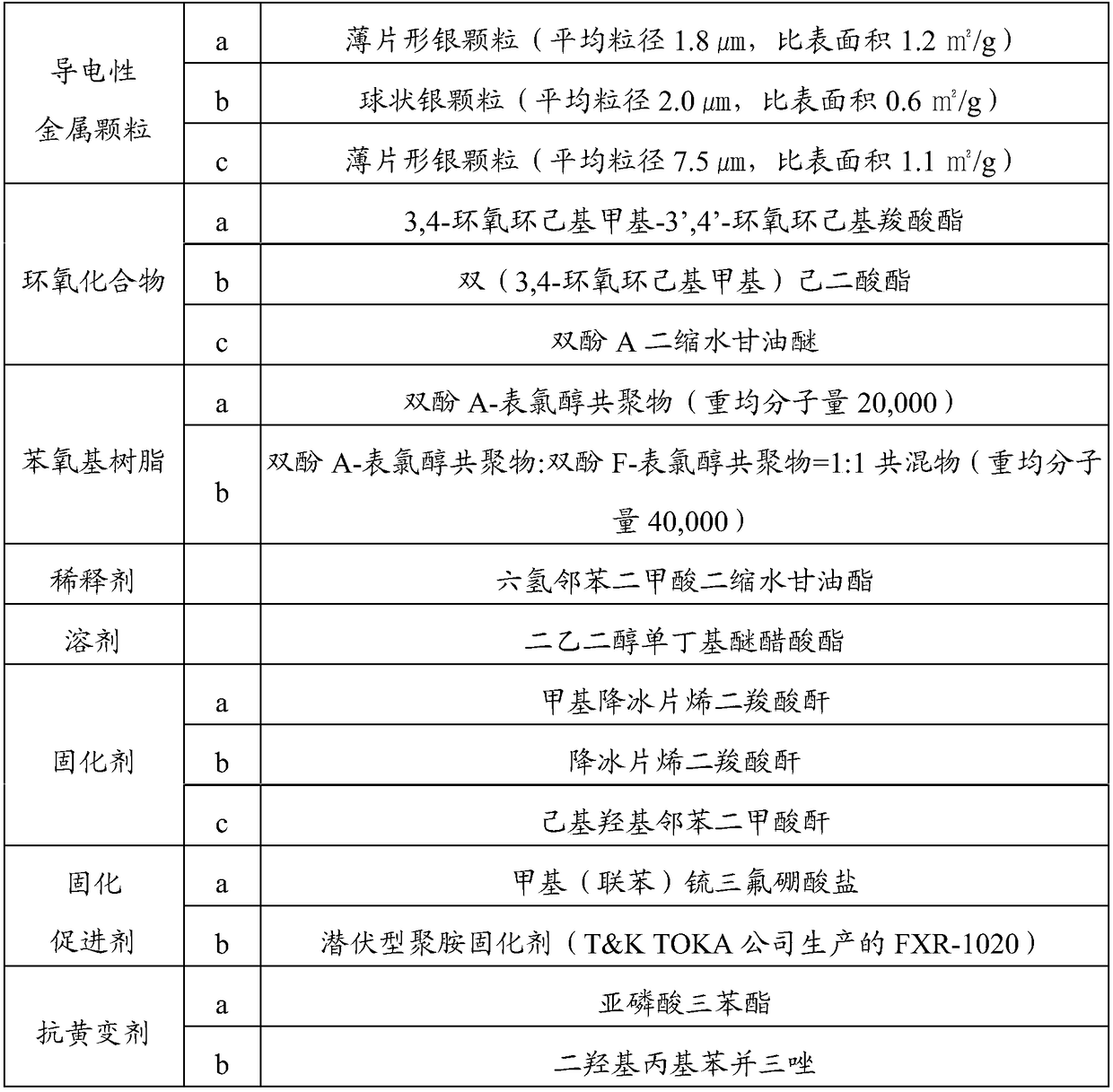

[0092] Preparation of Conductive Adhesives

[0093] According to the composition shown in Table 1 below, use a rotary agitator to mix conductive metal particles with epoxy compound, phenoxy resin, diluent or solvent, curing agent, curing accelerator and anti-yellowing agent for 1 hour When checking with the naked eye after the above stirring, after the particles are uniformly dispersed without agglomeration, use a three-roll mill (3-roll mill) to further disperse, and then further add a solvent or diluent for the second half of stirring, and then carry out Degassing to prepare a conductive adhesive.

[0094] [Table 2]

[0095]

[0096] Note: 1) means conductive metal particles (a) 50% by weight + conductive metal particles (b) 25% by weight + conductive metal particles (c) 25% by weight.

[0097] 2) % by weight represents the content of each component based on the total weight of the conductive adhesive composition.

[0098] 3) Parts by weight represent the content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com