A high-performance copper-iron alloy material and its preparation method by electroslag remelting

A technology of copper-iron alloy and electroslag remelting, which is applied in the field of non-ferrous metallurgy, can solve problems such as porosity, shrinkage cavity, alloy ingot inclusions, etc., and achieve the effect of compact structure, controllable process, and refined grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, the process of preparing high-performance copper-iron alloy material by electroslag remelting is as follows:

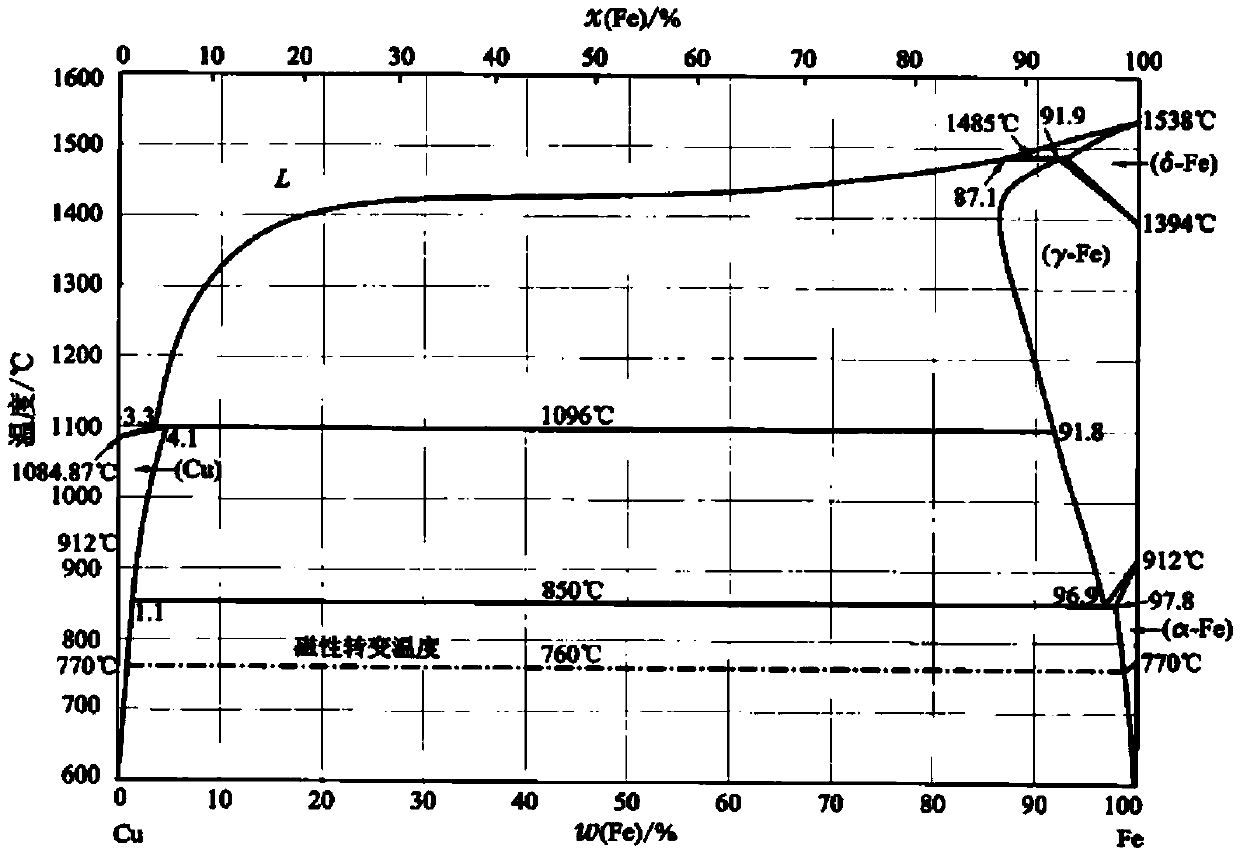

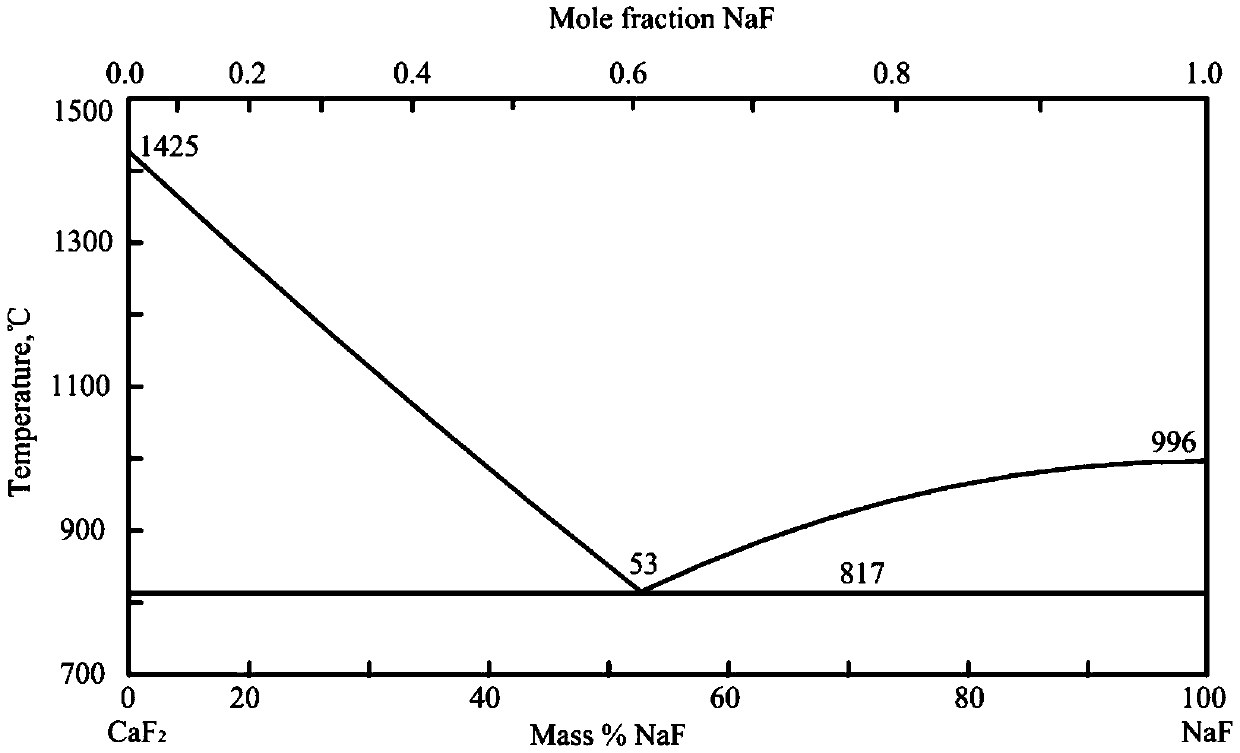

[0060] (1) adopt chemical composition to be (wt%): Fe=7.5%, Ce=0.009%, La=0.052%, the copper-iron alloy master alloy ingot that surplus is Cu is raw material; Slag system proportioning is: high-purity NaF The mass percentage is 18%, the balance is fluorite, and CaF in fluorite 2 The mass percentage content is not less than 98.5% and the mass percentage content of silicon dioxide is less than 1%. The copper-iron alloy electroslag remelting ingot prepared is shown in Figure 5 , the surface of the ingot is smooth after removing the surface slag crust.

[0061] (2) The copper-iron alloy electroslag ingot prepared by the method of electroslag remelting to prepare high-performance copper-iron alloy material has a uniform distribution of components, and a dense internal structure is formed through the electroslag remelting process. The copper-iro...

Embodiment 2

[0068] In this embodiment, the process of preparing high-performance copper-iron alloy material by electroslag remelting is as follows:

[0069] (1) adopt chemical composition to be (wt%): Fe=15%; Ce=0.01%, La=0.055%, the copper-iron alloy master alloy ingot that surplus is Cu is raw material; Slag system proportioning is: high-purity NaF The mass percentage is 20%, the balance is fluorite, and CaF in fluorite 2 The mass percentage content is not less than 98.5% and the mass percentage content of silicon dioxide is less than 1%. The prepared copper-iron alloy electroslag remelting ingot has a smooth surface after removing the surface slag crust. .

[0070] (2) The copper-iron alloy electroslag ingot prepared by electroslag remelting to prepare high-performance copper-iron alloy material has uniform composition distribution and compact internal structure. Image 6 (b).

[0071] (3) The copper-iron alloy electroslag ingot prepared by the method of electroslag remelting to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com