Membrane electrode for hydrogen-oxygen fuel cell and preparation method thereof, and hydrogen-oxygen fuel cell

A fuel cell, membrane electrode technology, applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of high production cost, poor transmission, poor performance, etc., and achieve high repeatability, simple process and high performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

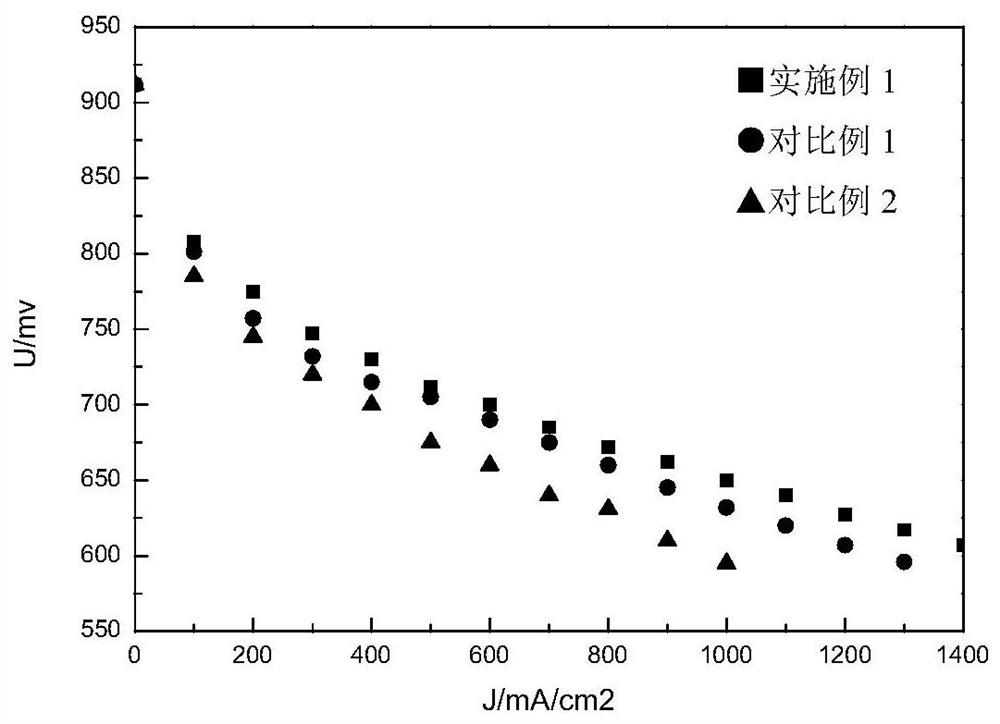

Examples

preparation example Construction

[0015] A method for preparing a membrane electrode for a hydrogen-oxygen fuel cell, comprising the steps of:

[0016] S1. Prepare catalyst slurry 1 and catalyst slurry 2;

[0017] S2. Spraying the catalyst slurry 1 on the proton exchange membrane to form the first catalytic layer;

[0018] S3. spray catalyst slurry 2 on the surface of the first catalytic layer to form a second catalytic layer;

[0019] Wherein, the noble metal content of catalyst 1 in catalyst slurry 1 is higher than the noble metal content of catalyst 2 in catalyst slurry 2, and the mass ratio of catalyst 2 and proton exchange membrane solution in catalyst slurry 2 is lower than that of catalyst in catalyst slurry 1. 1 to the mass ratio of the proton exchange membrane solution, the spraying speed of the catalyst slurry 2 is higher than that of the catalyst slurry 1, and the solid content in the catalyst slurry 2 is lower than that of the catalyst slurry 1.

[0020] Specifically, the proton exchange membrane...

Embodiment 1

[0035] A method for preparing a membrane electrode for a hydrogen-oxygen fuel cell, comprising the steps of:

[0036] S1. Preparation of catalyst slurry 1 and catalyst slurry 2:

[0037] S11. Catalyst 1 selects Pt / C with a Pt mass content of 60%, mixes Catalyst 1 and water at a mass ratio of 1:25, and alternately carries out ultrasonic dispersion and stirring to obtain A1 solution; Mix at a weight ratio of 1:20, alternately perform ultrasonic dispersion and stirring to obtain B1 solution; mix A1 solution and B1 solution and alternately perform ultrasonication and stirring to obtain catalyst slurry 1, in which catalyst 1 and proton exchange membrane The mass ratio of the solution is 1:3, and the solid content is 0.5%;

[0038] S12. Catalyst 2 selects Pt / C with a Pt mass content of 40%, mixes Catalyst 2 and water at a mass ratio of 1:25, and alternately carries out ultrasonic dispersion and stirring to obtain A2 solution; The weight ratio of 10 is mixed, and ultrasonic dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com