Composite barrier film with water and oxygen barrier function and preparation method thereof

A water-oxygen barrier and barrier film technology, applied in the field of functional polymers, can solve the problems of reducing water-oxygen barrier properties, increasing process complexity and production cost, and insufficient interface bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

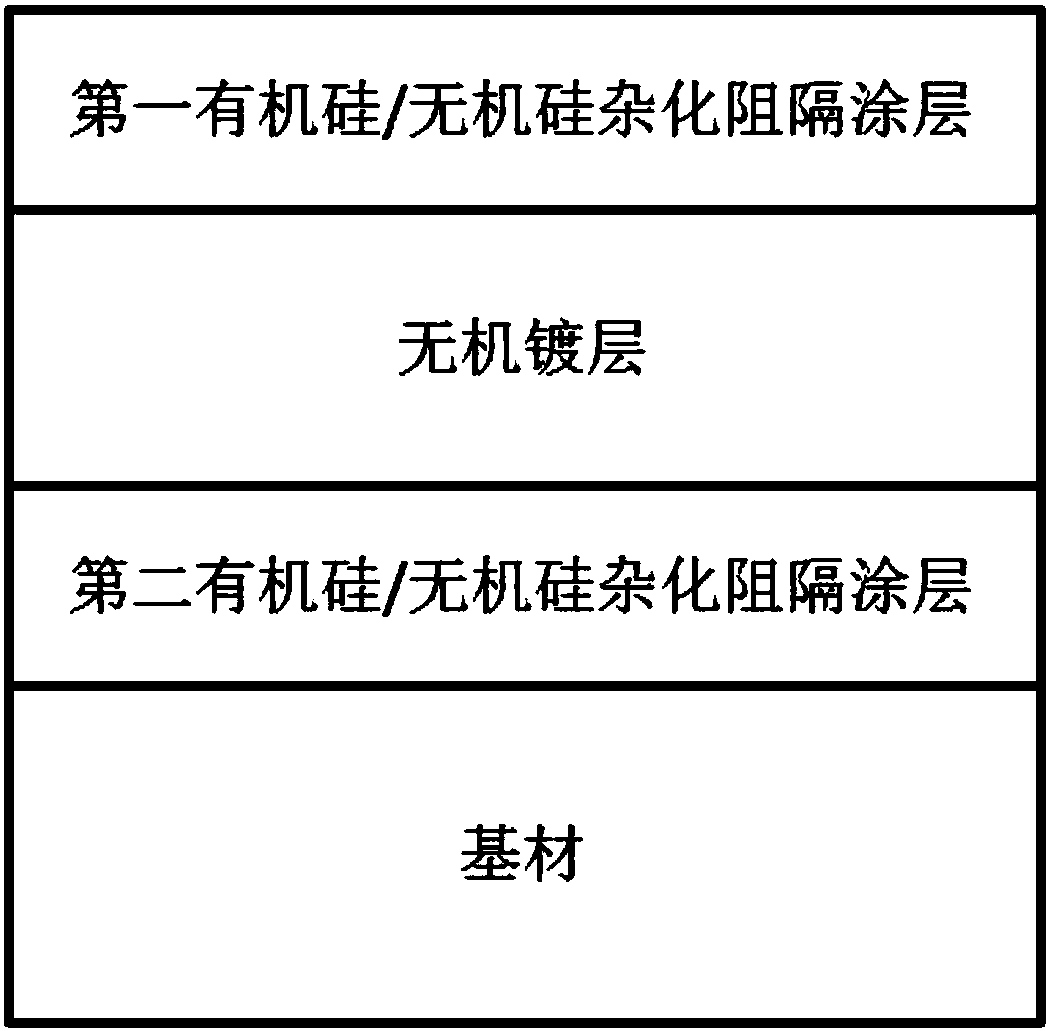

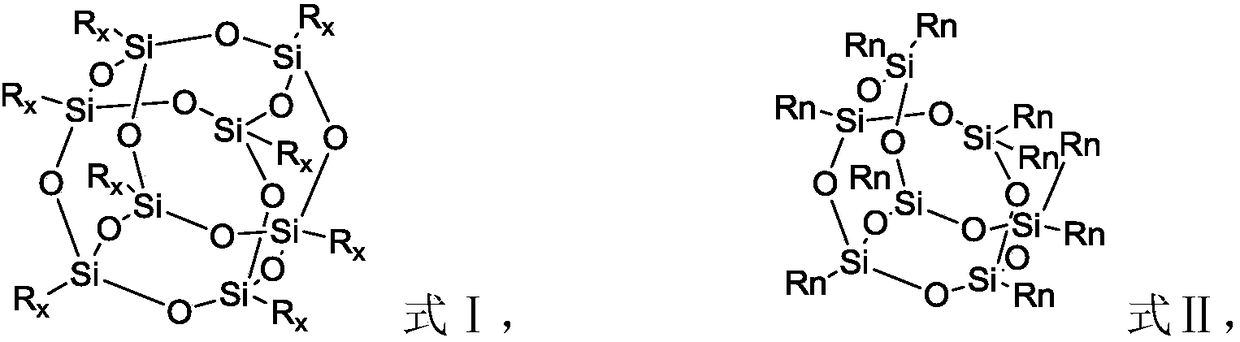

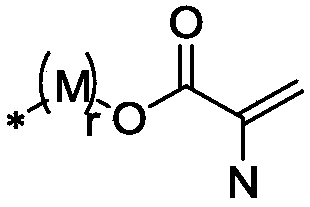

[0087] A composite barrier film with a water and oxygen barrier function, comprising a first organic silicon / inorganic silicon hybrid barrier coating, an inorganic coating, a second organic silicon / inorganic silicon hybrid barrier coating and a film substrate sequentially stacked; Wherein the first organosilicon / inorganic silicon hybrid barrier coating and the second organosilicon / inorganic silicon hybrid barrier coating consist of the following components calculated in parts by weight:

[0088]

[0089] The thickness of the first organic silicon / inorganic silicon hybrid barrier coating is 0.6 μm, the thickness of the second organic silicon / inorganic silicon hybrid barrier coating is 0.6 μm, and the inorganic coating is a silicon nitride coating with a thickness of 30 nm. The film substrate is a PET substrate with a thickness of 200 μm.

[0090] The preparation method of the composite barrier film with water and oxygen barrier function comprises the following steps:

[009...

Embodiment 2

[0097] A composite barrier film with water and oxygen barrier function, its composition and preparation method are basically the same as in Example 1, the only difference is that the polyfunctional cage polysilsesquioxane used in Example 2 is B.

Embodiment 3

[0099] A composite barrier film with water and oxygen barrier function, its composition and preparation method are basically the same as in Example 1, the only difference is that the polyfunctional cage polysilsesquioxane used in Example 3 is C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com