Potassium ion battery positive electrode material and preparation method thereof, potassium iodine battery

A battery positive electrode and potassium ion technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of battery energy density increase and achieve the effect of broad application prospects and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation process of potassium iodine battery is as follows:

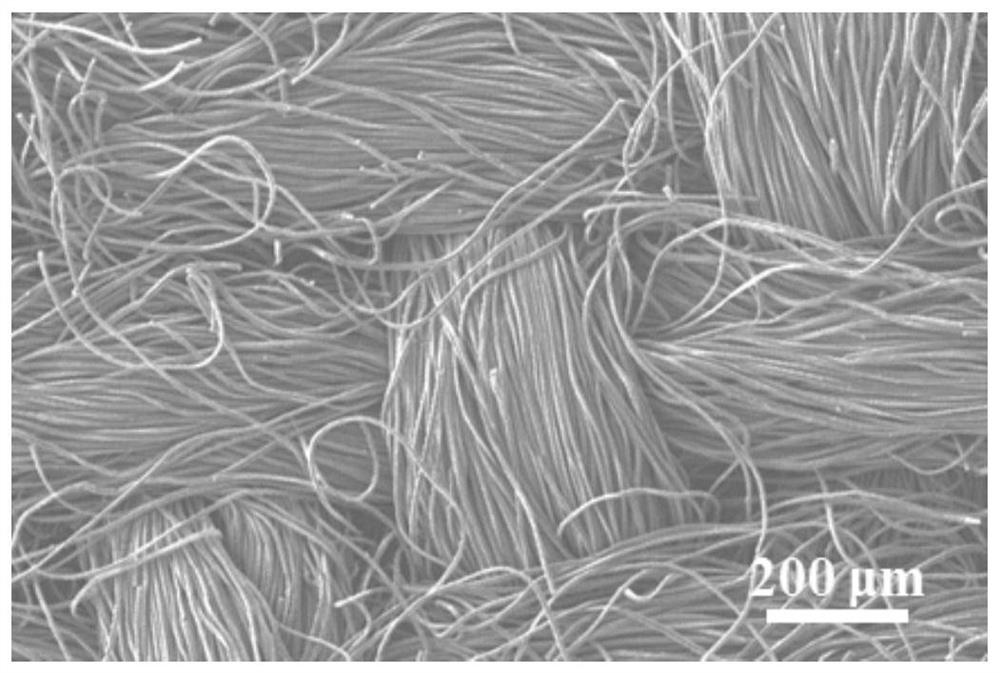

[0052] 1) Preparation of porous carbon cloth: immerse the commercial carbon cloth in 50mL KOH ethanol solution, the mass of KOH contained in the ethanol solution is the same as that of the added carbon cloth, and stir until dry at 80°C; Calcined at 700°C for one hour in a quartz tube furnace filled with inert gas, then washed repeatedly, and dried the porous carbon cloth.

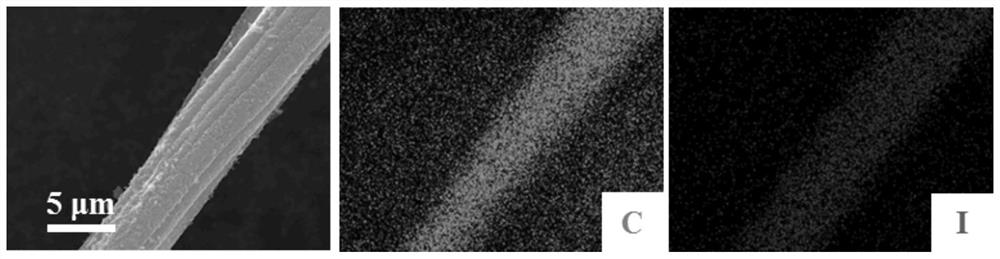

[0053] 2) Iodine-carbon is compounded by simple solution adsorption and internal packaging. The specific process is: dissolve 10mg iodine element in 20mL water. Since the solubility of iodine element in water is very low, there are many fine particles of iodine element in the solution. At this time, the porous carbon cloth is immersed in the above solution for a certain period of time, so that the iodine in the solution is absorbed by the carbon in the porous carbon cloth and encapsulated in the internal pores. Finally, the solution...

Embodiment 2

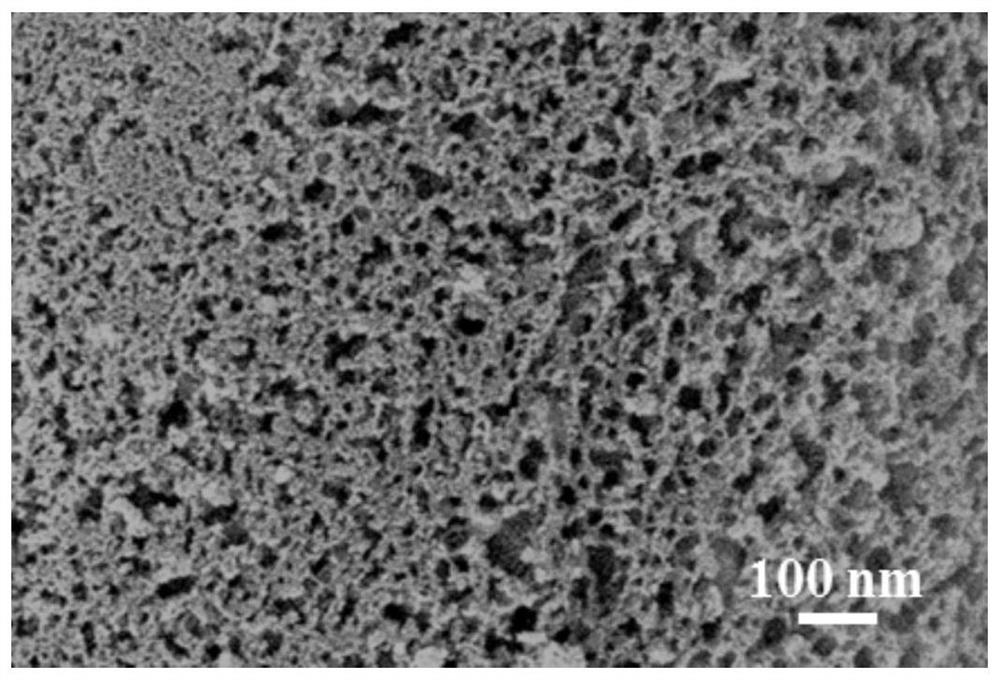

[0059] A positive electrode material for a potassium ion battery, the positive electrode material includes a porous carbon carrier and iodine elemental substance loaded on the porous carbon carrier, the interior of the porous carbon carrier is provided with micropores and mesopores, and the iodine elemental substance is adsorbed and filled in the mesopores of the porous carbon carrier and inside the pores.

[0060] Among them, in the porous carbon carrier, the pore diameter of the mesopore is 4.4nm, and the pore diameter of the micropore is 2nm; in the positive electrode material, the mass percentage of iodine is 29%.

[0061] The preparation method of the positive electrode material of the potassium ion battery comprises the following steps:

[0062] 1) The porous carbon carrier is prepared by alkali etching pore-forming method, specifically:

[0063] 1-1) Submerge the carbon support in an ethanol solution of KOH, and stir until dry at 90°C;

[0064] 1-2) Calcining the carbon...

Embodiment 3

[0071] A positive electrode material for a potassium ion battery, the positive electrode material includes a porous carbon carrier and iodine elemental substance loaded on the porous carbon carrier, the interior of the porous carbon carrier is provided with micropores and mesopores, and the iodine elemental substance is adsorbed and filled in the mesopores of the porous carbon carrier and inside the pores.

[0072] Wherein, in the porous carbon carrier, the pore diameter of the mesopore is 2nm, and the pore diameter of the micropore is 1.2nm; in the positive electrode material, the mass percentage of iodine is 44%.

[0073] The preparation method of the positive electrode material of the potassium ion battery comprises the following steps:

[0074] 1) The porous carbon carrier is prepared by alkali etching pore-forming method, specifically:

[0075] 1-1) Submerge the carbon support in an ethanol solution of KOH, and stir until dry at 70°C;

[0076] 1-2) Calcining the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com