Antimicrobial protection film aqueous solution and preparation method thereof

An anti-microbial and protective film technology, applied in the field of air purification, can solve the problems of low action rate, secondary pollution, easy saturation of filters, etc., to avoid secondary pollution, prevent cross-spreading of viruses, strong physical adsorption performance and The effect of ion exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

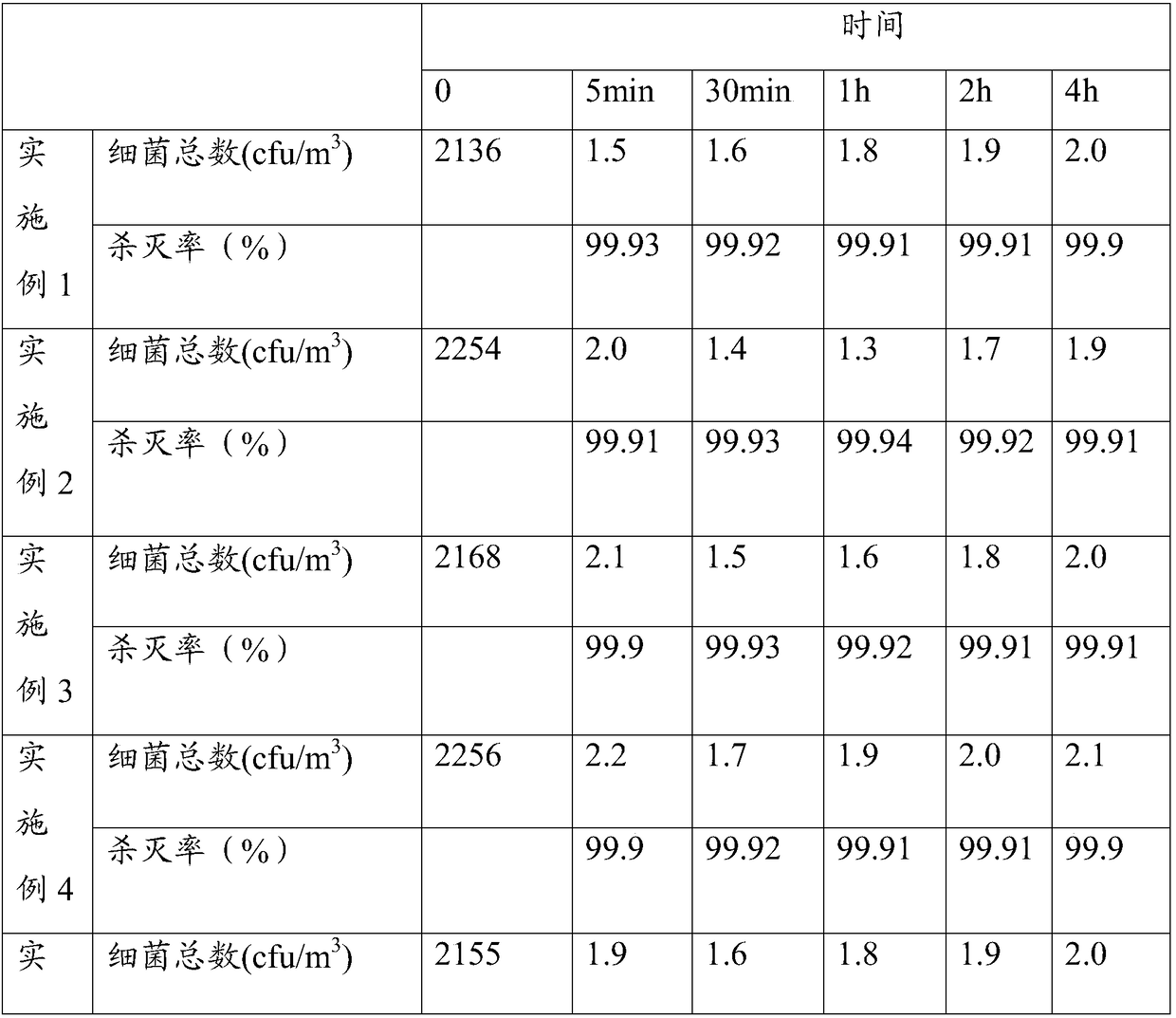

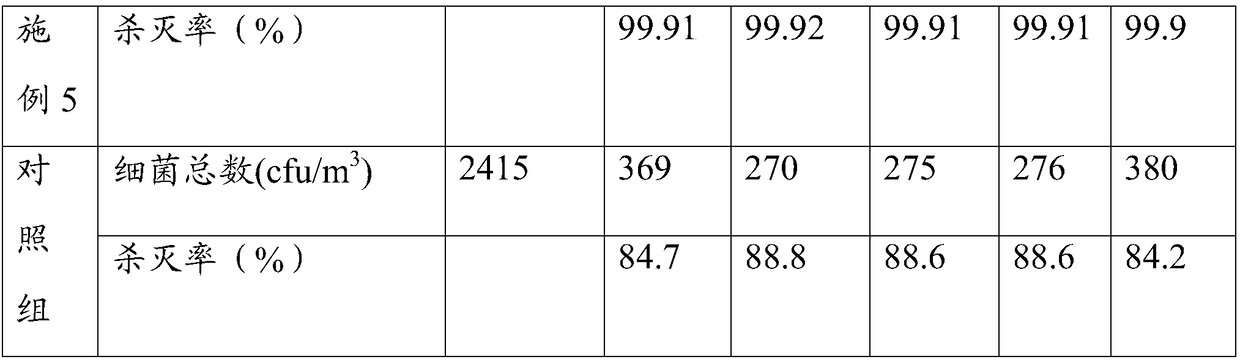

Examples

Embodiment 1

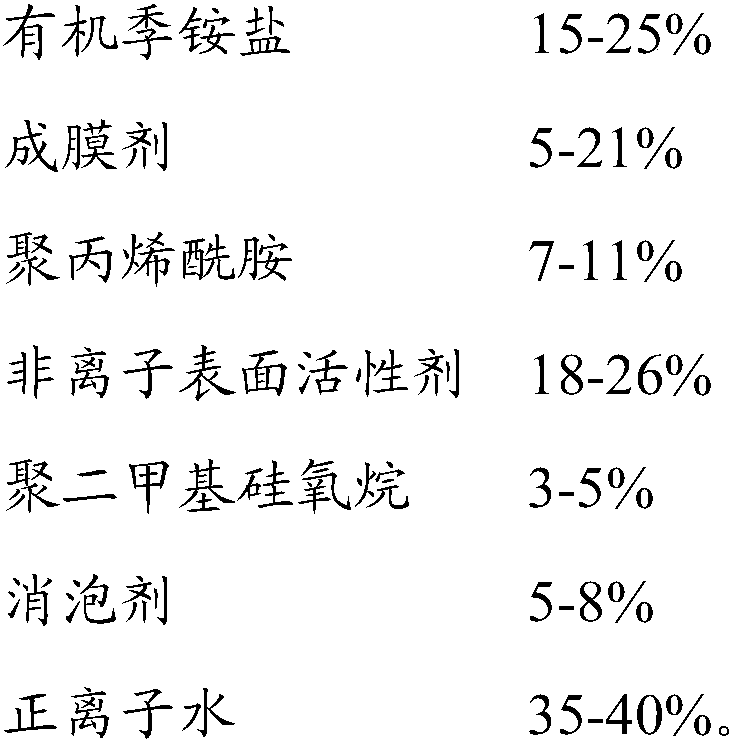

[0022] Microbial protective film water agent: 20g of tetrabutylammonium bromide, 8g of polyurethane, 9g of polyacrylamide, 22g of polyethylene glycol, 4g of polydimethylsiloxane, 7g of polysiloxane, and 37g of positive ion water.

[0023] The preparation method of above-mentioned raw material, comprises the following steps:

[0024] Step (1): Add positive ion water into the reactor, add polyurethane into the reactor at 25°C, and stir for 20 minutes to obtain mixture A;

[0025] Step (2): Add polyacrylamide and polyethylene glycol into the reactor containing mixture A in step (1), and stir at 25°C for 20 minutes to obtain mixture B;

[0026] Step (3): Add polydimethylsiloxane to the reactor containing mixture B in step (2), and stir at 25°C for 10 minutes to obtain mixture C;

[0027] Step (4): Add polyacrylamide to the reactor containing mixture C in step (3), and stir at 25°C for 20 minutes to obtain mixture D;

[0028] Step (5): Let the mixture D in step (4) stand for 18 m...

Embodiment 2

[0030] Microbial protective film water agent: tetrabutylammonium bromide 15g, polyurethane 5g, acrylate 8g, polyacrylamide 9g, polyethylene glycol 22g, polydimethylsiloxane 4g, polysiloxane 7g, positive ion water 37g.

[0031] The preparation method of above-mentioned raw material, comprises the following steps:

[0032] Step (1): Add positive ion water into the reactor, add polyurethane into the reactor at 25°C, and stir for 20 minutes to obtain mixture A;

[0033] Step (2): Add polyacrylamide and polyethylene glycol into the reactor containing mixture A in step (1), and stir at 25°C for 20 minutes to obtain mixture B;

[0034] Step (3): Add polydimethylsiloxane to the reactor containing mixture B in step (2), and stir at 25°C for 10 minutes to obtain mixture C;

[0035] Step (4): Add polyacrylamide to the reactor containing mixture C in step (3), and stir at 25°C for 20 minutes to obtain mixture D;

[0036] Step (5): Let the mixture D in step (4) stand for 18 minutes, fil...

Embodiment 3

[0038] Microbial protective film water agent: 20g of tetrabutylammonium bromide, 5g of dodecyltrimethylammonium chloride, 9g of polyurethane, 12g of acrylate, 11g of polyacrylamide, 26g of polyethylene glycol, polydimethylsiloxane Alkanes 5g, polysiloxane 8g, positive ion water 40g.

[0039] The preparation method of above-mentioned raw material, comprises the following steps:

[0040] Step (1): Add positive ion water into the reactor, add polyurethane into the reactor at 25°C, and stir for 20 minutes to obtain mixture A;

[0041] Step (2): Add polyacrylamide and polyethylene glycol into the reactor containing mixture A in step (1), and stir at 25°C for 20 minutes to obtain mixture B;

[0042] Step (3): Add polydimethylsiloxane to the reactor containing mixture B in step (2), and stir at 25°C for 10 minutes to obtain mixture C;

[0043] Step (4): Add polyacrylamide to the reactor containing mixture C in step (3), and stir at 25°C for 20 minutes to obtain mixture D;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com