Antibacterial marc paper-type edible packing film

A fruit pomace, antibacterial technology, applied in the field of antibacterial fruit pomace paper-type edible packaging film, can solve the problems of poor antibacterial performance, unsuitable for long-term storage of packaged food, etc., achieve good peeling performance, crisp and pleasant taste, and extend the shelf life and storage time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

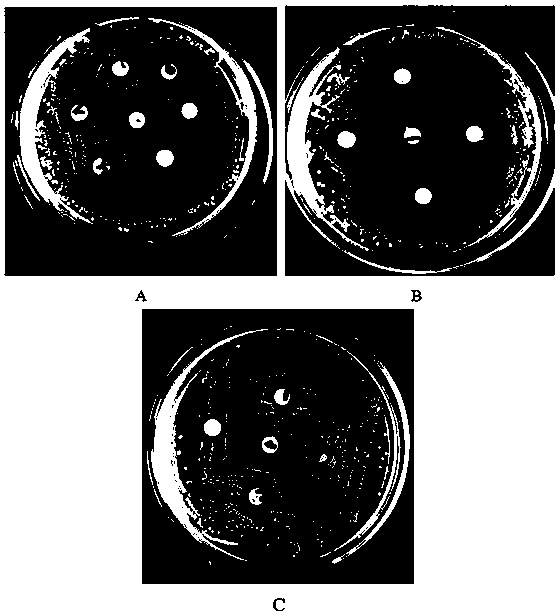

Image

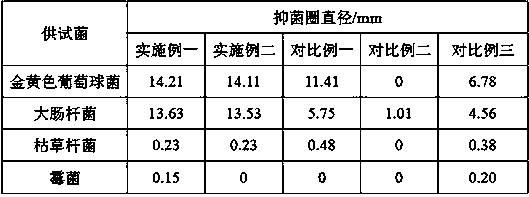

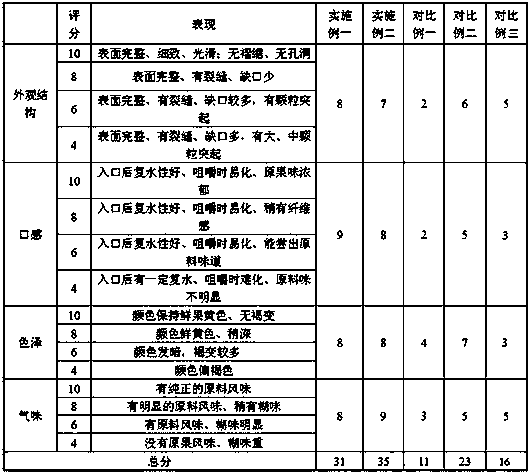

Examples

Embodiment 1

[0028] Embodiment one: the preparation of citrus / olive pomace paper film

[0029] (1) Select fresh citrus and olives with full grains, no signs of pest damage and rot, and pre-clean them with water jets to remove pesticides, dust, and sundries on the surface of the fruits, and then put them into the brush cleaning machine for 2~3 days. Second; use a squirrel cage crusher to crush until the particle size is 3-4cm, then squeeze the juice with a squeezer; use a shredder to finely chop the fruit pomace after the juice;

[0030] (2) Take 200g each of the two kinds of fruit pomace obtained in step (1) into a beater, add 200g of deionized water, 8g of sucrose, 1.2g of salt, 0.8g of five-spice powder, 3.6g of plantain and taro powder, and the modified wheat Gluten protein 2.4g, citric acid 1.6g, glycerin 5g, beating at room temperature at a speed of 1050r / min for 35min, and homogenizing twice through a colloid mill, so that the average particle size of pomace fiber molecules reaches 5...

Embodiment 2

[0035] Embodiment two: the preparation of navel orange / apple / snow pear residue paper type film

[0036] (1) Select fresh navel oranges, apples and snow pears with full grains, no signs of pest damage and rot, and pre-clean them with jet water to remove pesticides, dust and sundries on the surface of the fruits, and then put them into the brush cleaning machine for cleaning 2 ~3 times; use a squirrel cage crusher to crush until the particle size is 3~4cm, and then squeeze the juice with a squeezer; use a shredder to finely chop the juiced fruit pomace;

[0037] (2) Take 50g of each of the three types of fruit pomace obtained in step (1) in a beater, add 75g of deionized water, 4g of sucrose, 0.6g of salt, 0.7g of five-spice powder, 1.3g of plantain taro powder, and the modified wheat Gluten protein 1.1g, citric acid 0.6g, glycerin 2.1g, beating at room temperature at a speed of 1050r / min for 35min, and homogenizing twice through a colloid mill, so that the average particle size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com